Method for modifying micro-fluidic chip by using chiral selective magnetically-functionalized graphene

A microfluidic chip and selective technology, applied in the field of micro-total analysis, can solve the problems of high-efficiency loading of unfavorable biomolecules and maintenance of biological activity, etc., to achieve the effect of improving the reuse rate, simple and controllable operation, and saving modification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

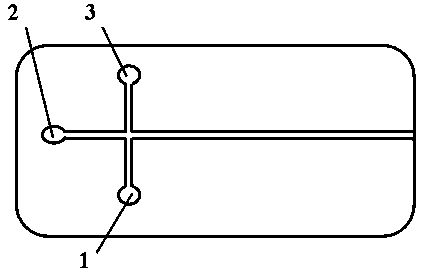

[0036] Fabrication of PDMS chip: Using the GaAs positive mold (produced by the 55th Institute of Electronics in Nanjing) as a template, fabricate a typical cross-shaped PDMS microfluidic chip channel, such as figure 1 shown. The specific production process is as follows: Take a certain amount of PDMS monomer and curing agent according to 10:1 (mass ratio), mix evenly, degas, pour on the GaAs template, and cure at 70 oC for 2 hours. After cooling, peel off the PDMS chip containing the cross-shaped channel from the template, cut it into the desired shape with a blade, and punch holes in the buffer pool, sample pool and sample waste pool with a puncher to form a diameter of 3 mm holes. At the same time, using the smooth glass plate as a template, follow the same steps to prepare a PDMS chip without microchannels as a cover slip. The PDMS chip containing the cross channel and the PDMS cover sheet without the channel were ultrasonically cleaned with secondary water, methanol, and...

Embodiment 2

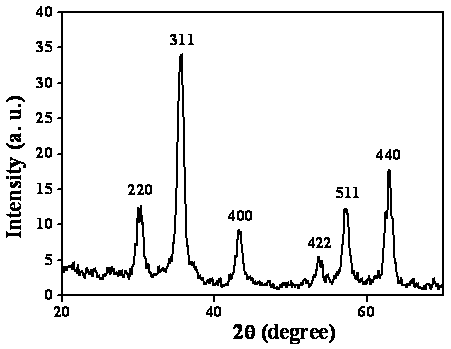

[0038] (1) Using the improved Hummers method (Hummers W S, Offeman R E. Journal of the American Chemical Society, 1958, 80(6): 1339~1339. Cote L J, Kim F, Huang J. Journal of the American Chemical Society, 2009, 131(3): 1043~1049. Shin H J, Kim K K, Benayad A, et al. Advanced Functional Materials, 2009, 19(12): 1987~1992) Preparation of GO: 0.5 g graphite powder and 0.5 g NaNO 3 Added to 23 mL of 18 mol / L concentrated H 2 SO 4 In ice bath, slowly add 3 g KMnO 4 , after stirring well to make it evenly mixed, transfer the solution to a water bath at 35 ± 5 °C and stir for an hour to form a beige paste. Add 40 mL of water, stir at room temperature for 30 min, then dilute to 140 mL with water. Add 3 mL of 30% H2 dropwise 2 o 2, the solution turned from dark brown to bright yellow. The obtained product was filtered while it was hot, and the product was centrifuged and washed with double distilled water until the supernatant was neutral, and centrifuged at a speed of 12000 r...

Embodiment 3

[0045] GO / Fe 3 o 4 Modification process of / BSA composite on the surface of PDMS microchannel

[0046] (1) The manufacturing process of the simple PDMS microfluidic chip refers to the steps in Example 1.

[0047] (2) GO / Fe 3 o 4 Modification process of / BSA composite material on the surface of PDMS microchannel: First, the PDMS channel was rinsed with double distilled water for 10 min; a permanent magnet was placed on the upper and lower sides of the chip (attracted poles facing each other), and the prepared 2 mg mL -1 GO / Fe 3 o 4 / BSA composite was continuously pumped into the separation pipe for 5 min, and under the action of an external magnetic field, the GO / Fe 3 o 4 The / BSA composite was quickly and controllably immobilized in the PDMS channel, and the modified chip was placed in the refrigerator for 1 hour; the channel was continuously washed with buffer solution for 5 min to wash off the residue in the separation channel, and the GO chip was obtained. / Fe 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com