Method for preparing hydro-demetalization catalyst

A technology for hydrodemetallation and catalysts, which is applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve problems such as affecting catalyst activity, and improve activity stability. , to avoid uneven distribution, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

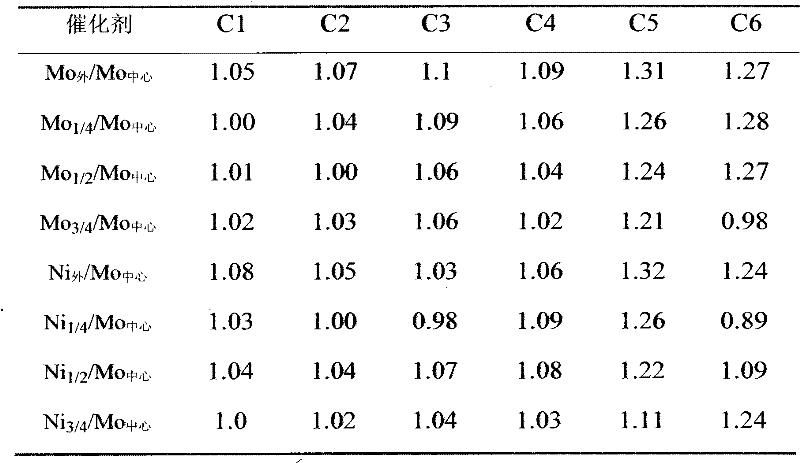

Examples

example 1

[0024] Weigh the pore volume as 0.95ml / g and the specific surface area as 200m 2 100 grams of γ-phase cylindrical strip-shaped alumina carrier / g, add 150ml Mo-Ni-NH 3 solution (with MoO 3 12.0wt%, NiO3.0wt%) impregnated for 2 hours, filter off the excess solution, put the impregnated wet catalyst in the atmosphere roasting furnace, feed water vapor, control the pressure of water vapor in the furnace cavity to be the saturated steam of the steam Pressing pressure, the roasting furnace heats up slowly, and the heating rate is 5°C·min -1 After the temperature rose to 80°C, the temperature was kept constant for 3 hours, then the water vapor was stopped, and dry air was passed in, and dried at 100°C for 3 hours. The dried catalyst was calcined at 550° C. for 4 hours to obtain the hydrodemetallization catalyst C1 of the present invention.

example 2

[0026] Same as Example 1, except that the mixed gas of water vapor and air is fed in, wherein water vapor accounts for 70% by volume, the temperature is raised to 100°C, and the temperature is kept constant for 2 hours, then the water vapor atmosphere is stopped, and dry air is passed in, and dried at 120°C for 2 hours. Hour. The dried catalyst was calcined at 550° C. for 4 hours to obtain the hydrodemetallization catalyst C2 of the present invention.

example 3

[0028] Same as Example 1, except that the mixed gas of water vapor and nitrogen is fed, wherein water vapor accounts for 80% by volume, the temperature is raised to 110°C, and the temperature is kept constant for 2 hours, then the water vapor atmosphere is stopped, and dry air is passed in, and dried at 130°C for 2 hours. Hour. The dried catalyst was calcined at 550° C. for 4 hours to obtain the hydrodemetallization catalyst C3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com