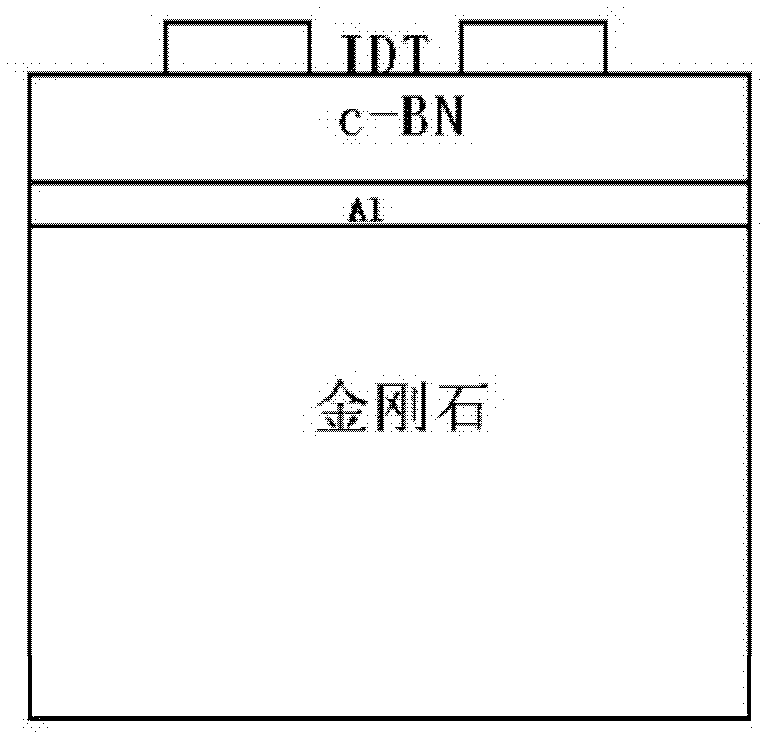

Cubic boron nitride piezoelectric film surface acoustic wave device and preparation method thereof

A surface acoustic wave device, boron nitride piezoelectric technology, applied in the direction of electrical components, impedance networks, etc., to achieve high frequency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a cubic boron nitride piezoelectric thin film surface acoustic wave device, comprising the steps of:

[0029] 1) Prepare nano-Al film on the surface of nano-CVD diamond substrate by DC magnetron sputtering:

[0030] Nano-Al films were prepared on the surface of nano-CVD diamond substrates using a DC magnetron sputtering system. The specific process parameters were: the background vacuum was 3.3×10 -4 Pa, the rotation speed of the substrate turntable is 20 rpm, the substrate temperature is room temperature, the sputtering power is 50w, the argon gas flow rate is 20sccm, the working pressure is 1.0Pa, the target base distance is 6.5cm, and the deposition time is 12 minutes;

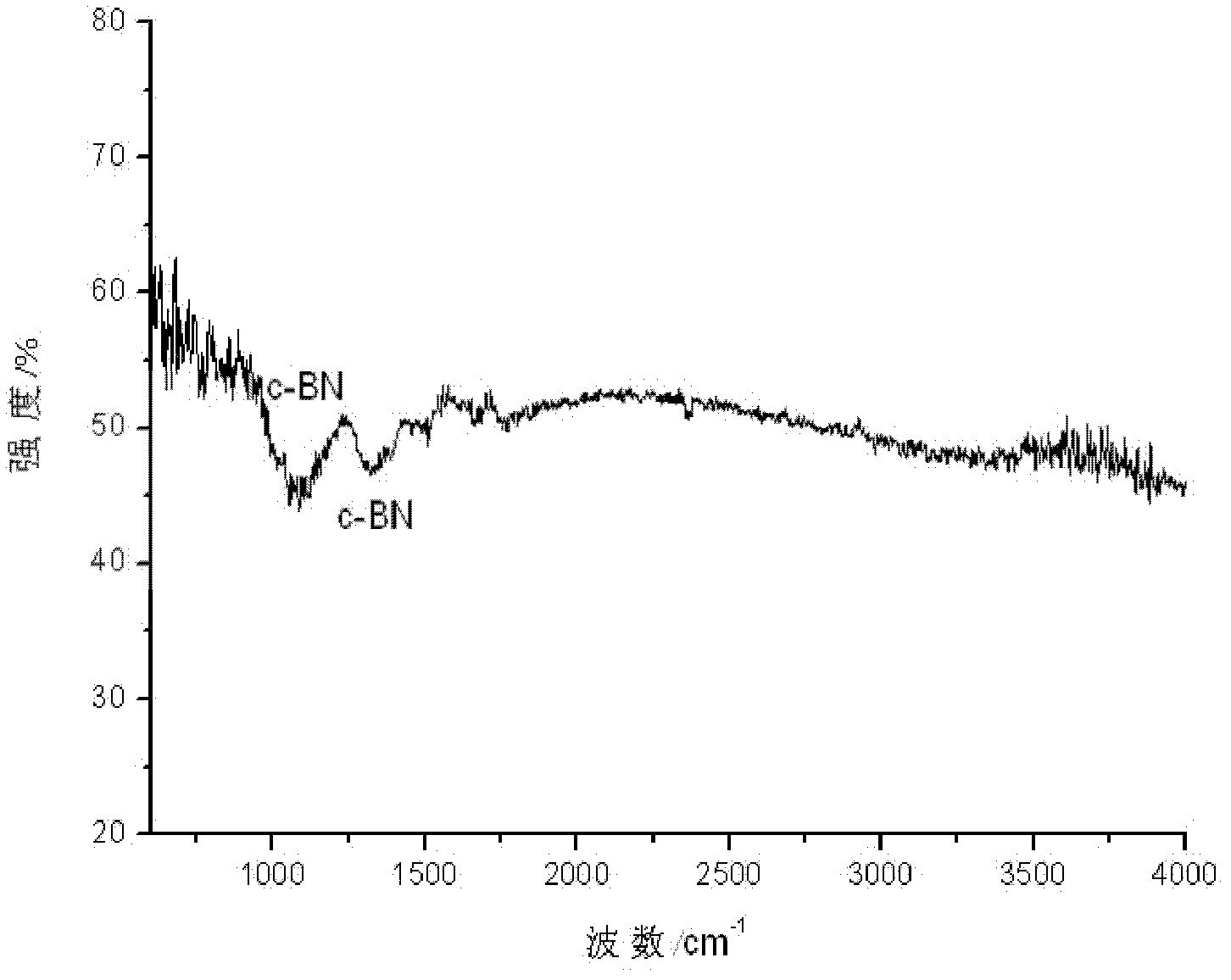

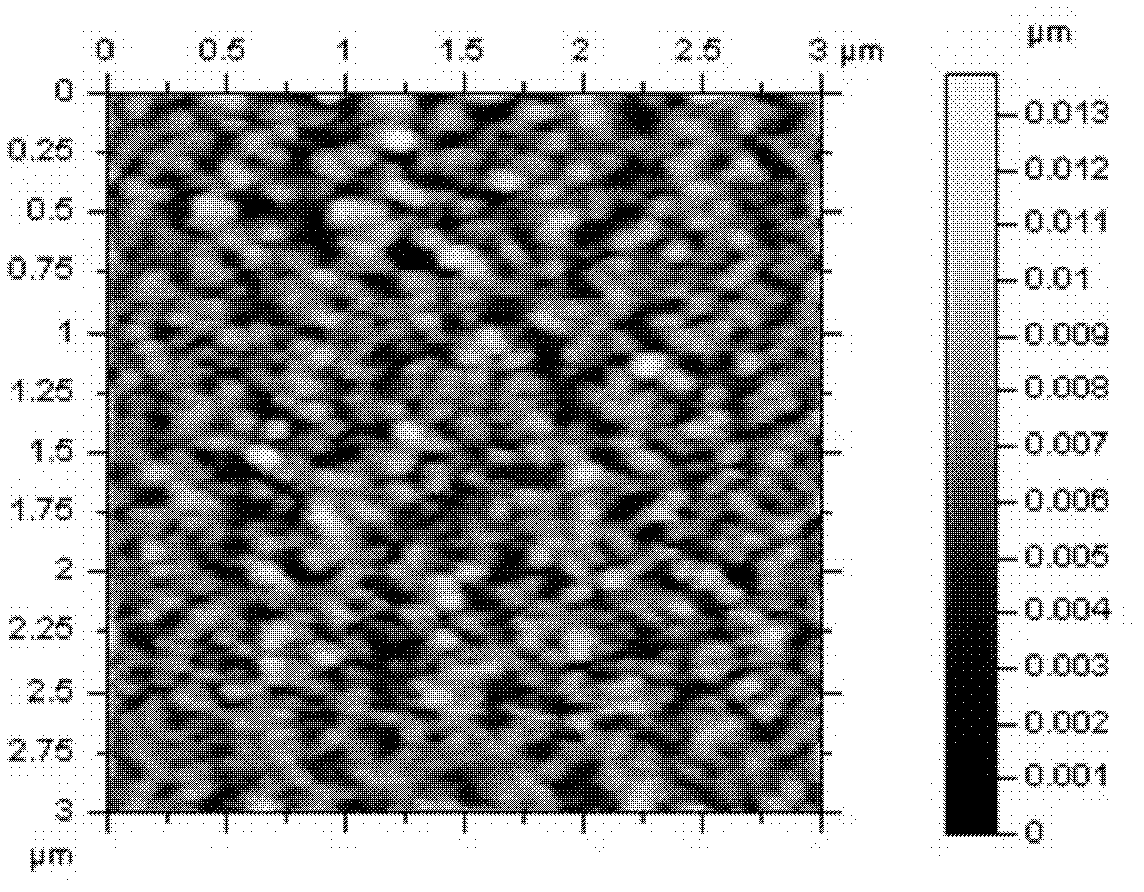

[0031] 2) Prepare nano-cubic boron nitride c-BN film on the surface of nano-Al film by radio frequency magnetron sputtering method:

[0032] Using radio frequency magnetron sputtering system to deposit nano-cubic boron nitride c-BN film can be realized at low temperature and l...

Embodiment 2

[0038] A method for preparing a cubic boron nitride piezoelectric thin film surface acoustic wave device, comprising the steps of:

[0039] 1) Prepare nano-Al film on the surface of nano-CVD diamond substrate by DC magnetron sputtering:

[0040] Nano-Al films were prepared on the surface of nano-CVD diamond substrates using a DC magnetron sputtering system. The specific process parameters were: the background vacuum was 3.3×10 -4 Pa, the rotation speed of the substrate turntable is 20 rpm, the substrate temperature is room temperature, the sputtering power is 50w, the argon gas flow rate is 18sccm, the working pressure is 1.0Pa, the target base distance is 6.5cm, and the deposition time is 12 minutes;

[0041] 2) Prepare nano-cubic boron nitride c-BN film on the surface of nano-Al film by radio frequency magnetron sputtering method:

[0042] Using radio frequency magnetron sputtering system to deposit nano-cubic boron nitride c-BN film can be realized at low temperature and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com