Testing system for researching flow boiling heat transfer character and pressure drop character of cryogenic fluid

A technology of boiling heat transfer and pressure drop characteristics, applied in low temperature engineering and low temperature field, can solve the problems of high overall system integration, unavailability, limited capacity of evaporation pressure, etc., to simplify complexity, reduce test cost and improve utilization efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

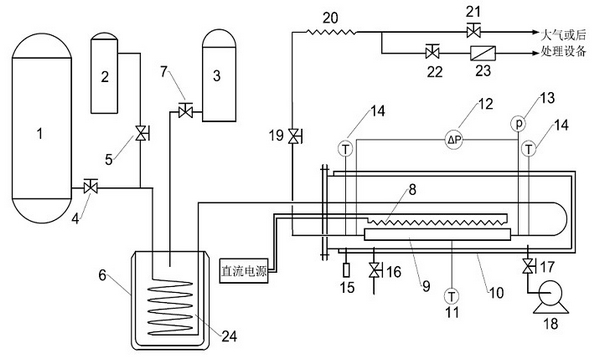

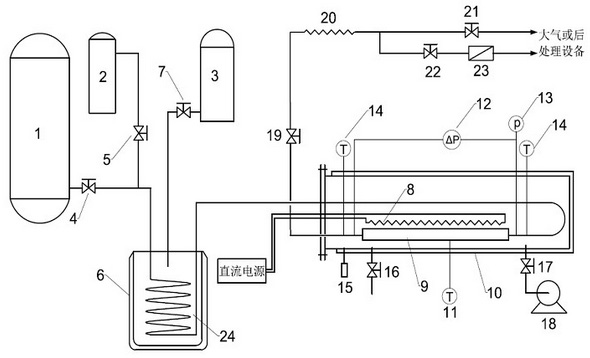

[0020] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0021] Such as figure 1As shown, the present invention includes a low-temperature self-pressurized storage tank 1, a nitrogen cylinder 2, a liquid nitrogen cylinder 3, a pressure regulating valve 4, a nitrogen valve 5, a wide-mouth Dewar 6, a liquid nitrogen valve 7, and an electric heating device 8, to be tested Heat exchange equipment 9, test vacuum dewar 10, wall temperature sensor 11, inlet and outlet differential pressure sensor 12, inlet pressure sensor 13, inlet and outlet temperature sensor 14, vacuum gauge 15, vacuum valve 16, evacuation valve 17, vacuum pump 18, Flow regulating valve 19, vaporizer 20, vent valve 21, on-off valve 22, gas flow meter 23, cooling coil 24. Among them, the cooling coil 24 is placed in the wide-mouth Dewar 6 to form a pre-cooling device; the vacuum pump 18 is connected to the test vacuum Dewar 10 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com