Successive-compounding-process based plugging method for well drilling

A plugging method and technology of composite method, which are applied in drilling compositions, chemical instruments and methods, earthwork drilling, etc., can solve the problem of low plugging success rate, narrow application range, and difficulty in improving the pressure bearing capacity of weak formations, etc. problems, to achieve the effect of high success rate of plugging, improving the success rate of plugging, and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

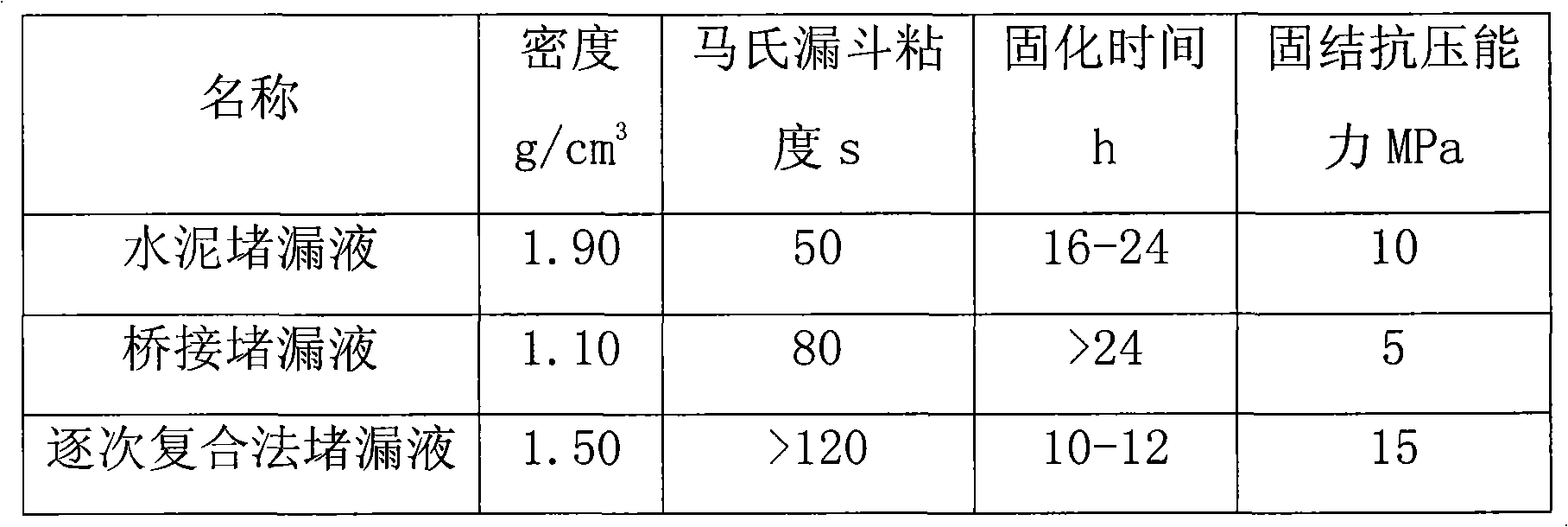

[0072] Embodiment: successive compound method plugging method of the present invention

[0073] First mix 12m3 cement slurry, the formula is: 2400g cement, natural plant fiber (0.3%), polyacrylate fluid loss reducer (3%), rubber particle high-strength proppant (3%), expansion fiber anti-cracking agent (0.2 %), cement mortar defoamer (0.2%). Add 8m3 bridge plugging slurry, the formula is: calcium carbonate powder (5%), saw foam (7%), medium particle composite plugging agent (including rice husk, walnut shell, cottonseed husk) (3%), medium particle walnut The shell (1.5%) and high carbon fiber (3%) are combined to make 20m3 of successive composite plugging slurry.

[0074] At 1:30 on the 20th, the drilling tool was lowered to 2111m without any obstruction. After the water hole was topped, the leakage plugging fluid was pumped in successively according to the ratio of 6:4, with a displacement of 50SPM, and a total of 17m3 was pumped; m3, 3.5m3 is left inside the drill pipe.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com