Magnesium alloy with good millability and preparation method of magnesium alloy plate

A magnesium alloy and performance technology, applied in the field of preparation of magnesium alloys and their sheets, can solve the problems of poor rollability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

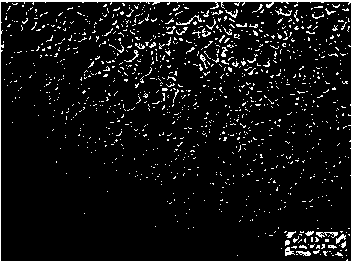

[0026] Using a resistance melting furnace, under the protection of No. 2 flux, metal magnesium is melted and heated to 730°C for melting. According to the mass percentage of the magnesium alloy, 4% of Zn, 3% of Cu and 0.4% of Mn are added to obtain the magnesium alloy. The melt is purified with hexachloroethane and No. 2 flux, and cooled to 680°C after stirring; in SF with a volume ratio of 1:10 6 and CO 2 Under the protection of the formed mixed gas, the magnesium alloy ingot is prepared by low-frequency electromagnetic oil-slip semi-continuous casting. The casting speed is 135mm / min, the water volume is 25L / min, and the electromagnetic conditions are: the electromagnetic frequency is 30Hz, and the number of ampere turns is 5500AT. Magnesium alloy slab with specifications of 200mm×60mm×1800mm, chemical analysis composition Mg-3.35Zn-2.73Cu-0.16Mn, attached figure 1 Its typical casting structure; anneal the slab at 400°C for 10 hours, mill the surface after annealing, select ...

Embodiment 2

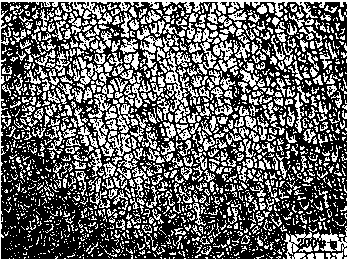

[0030] Using a resistance melting furnace, under the protection of No. 2 flux, metal magnesium is melted and heated to 740°C for melting. According to the mass percentage of the magnesium alloy, 4% of Zn, 3% of Cu and 0.5% of Zr are added to obtain the magnesium alloy. The melt was purified with hexachloroethane and No. 2 flux, and cooled to 685°C after stirring; in SF with a volume ratio of 1:10 6 and CO 2 Under the protection of the formed mixed gas, the magnesium alloy ingot is prepared by low-frequency electromagnetic oil-lubricating semi-continuous casting. The casting speed is 100mm / min, the water volume is 30L / min, and the electromagnetic conditions are: the electromagnetic frequency is 30Hz, and the number of ampere turns is 5500AT. Magnesium alloy slab with specifications of 200mm×60mm×1800mm and composition of Mg-4.01Zn-2.95Cu-0.3Zr according to chemical analysis, attached figure 2 Its typical casting structure; anneal the slab at 400°C for 10 hours, mill the surfa...

Embodiment 3

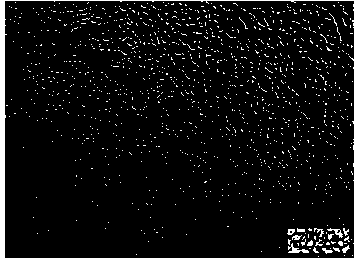

[0034] Using a gas-fired melting furnace, under the protection of No. 5 flux, melt the magnesium metal and heat it to 740°C to melt it. According to the mass percentage of the magnesium alloy, add 1.5% Zn, 4% Cu, and 0.8% Nd to obtain the magnesium alloy. The melt is purified with hexachloroethane and No. 5 flux, and cooled to 690°C after stirring; in SF with a volume ratio of 1:10 6 and CO 2 Under the protection of the formed mixed gas, the magnesium alloy ingot is prepared by low-frequency electromagnetic oil-lubricating semi-continuous casting. The casting speed is 100mm / min, the water volume is 30L / min, and the electromagnetic conditions are: the electromagnetic frequency is 30Hz, and the ampere-turn is 3500AT. Magnesium alloy slab with specifications of 200mm×60mm×1800mm, chemical analysis composition Mg-1.22Zn-3.62Cu-0.66Nd, attached image 3Its typical casting structure; anneal the slab at 420°C for 24 hours, mill the surface after annealing, select a sample with a siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com