A laser rotary cutting marking method on the surface of hard and brittle materials

A hard and brittle material, laser marking machine technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of material cracking, affecting the clarity of marking, etc., to avoid cracking, good marking effect, good effect clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

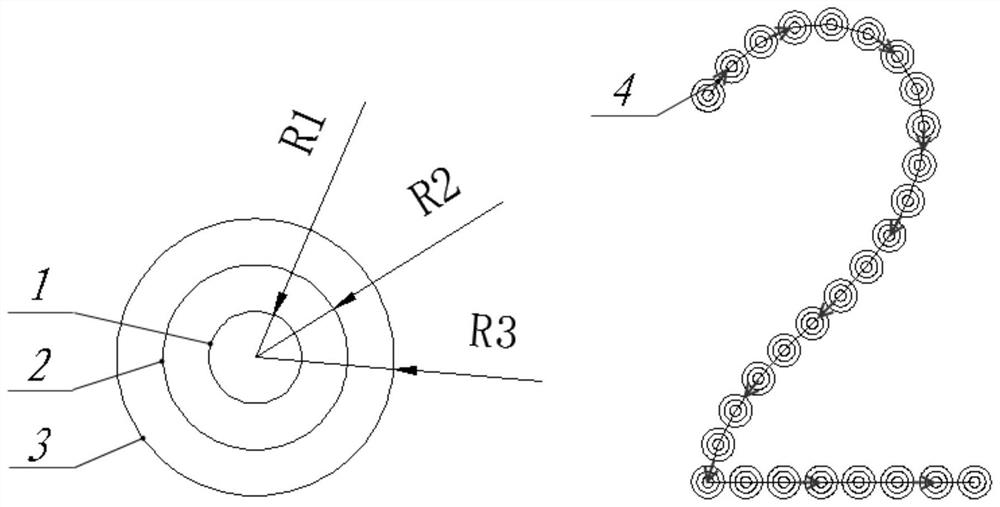

[0015] In this example, the laser is a pulsed fiber laser, the single pulse energy of the laser is 1mj, the frequency is 20KHZ, the pulse width of the laser beam is 10ns, the wavelength is 1064nm, the diameter of the laser spot is 0.05mm, the scanning speed is 1m / s, and the hard and brittle material is nitrogen Silicon. The shape of the character is number 2, and the width W is 0.14mm. Specific steps are as follows:

[0016] Step 1: Determine the fitting path 4 of laser marking as the number "2";

[0017] Step 2: According to the laser spot diameter and the character width, the number of rotary cutting paths scanned by the laser is n=3, the radius R1 of the first rotary cutting path 1 is 0.025mm, and the radius R2 of the second rotary cutting path 2 is 0.075mm. The radius R3 of the three rotary cutting paths 3 is 0.125 mm, and the distance between adjacent rotary cutting paths is 0.05 mm.

[0018] Step 3: Make the laser beam of the laser marking machine complete the first r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com