Titanium-based amorphous brazing alloy foil strip for brazing and preparation method for foil strip

A brazing filler metal, titanium-based technology, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc., can solve the adverse effects of intermetallic compound joint performance, titanium-based powder brazing filler metal can not meet the requirements of small structural parts and complex structures Problems such as the use of parts and low liquidus temperature, etc., to improve the assembly difficulty, superior brazing process, and improve the effect of band formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

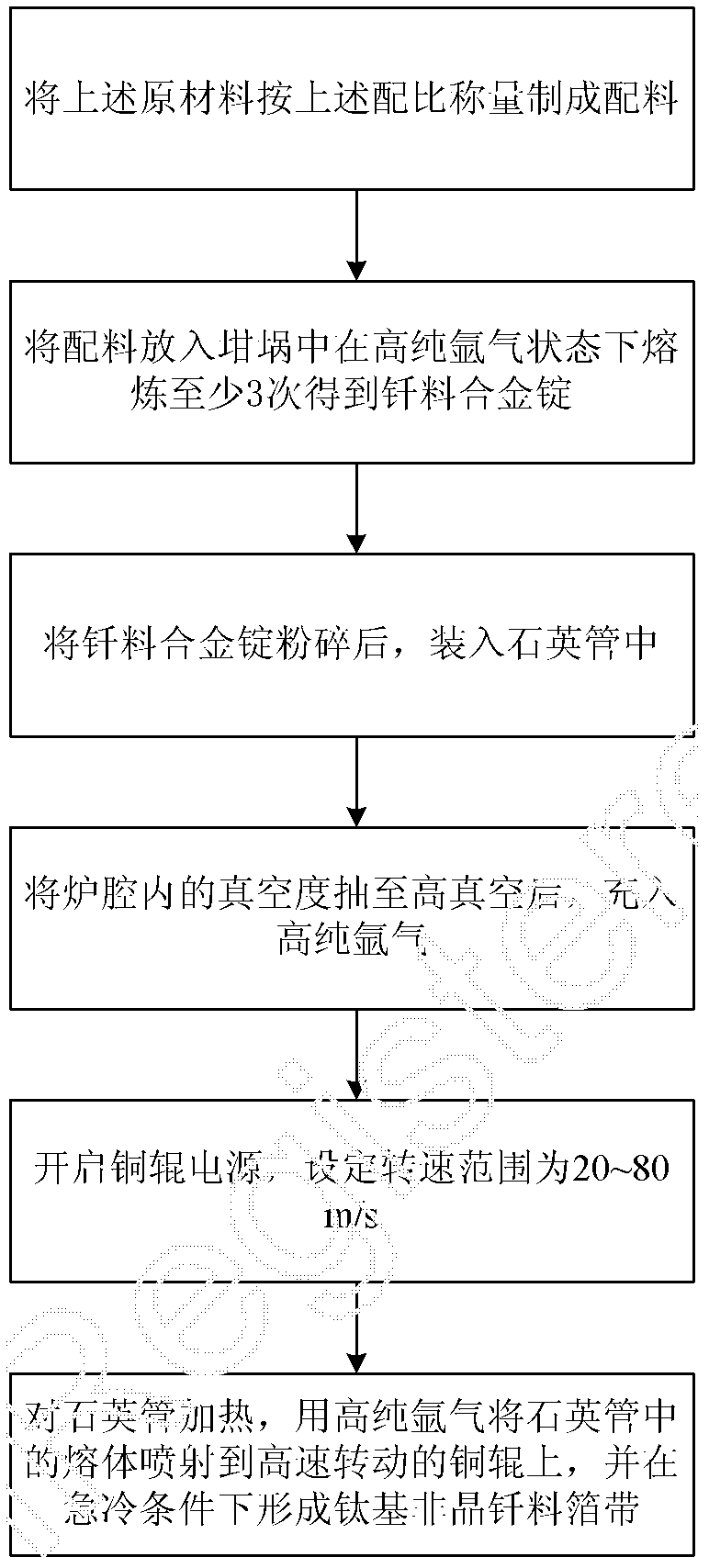

[0030] The present invention also provides a preparation method of a titanium-based amorphous solder foil for brazing, comprising the following steps:

[0031] (1) weighing the above-mentioned raw materials according to the above-mentioned proportioning ratio to make batching;

[0032] (2) Put the ingredients into the crucible and smelt at least 3 times under high-purity argon to obtain the solder alloy ingot;

[0033] (3) After the solder alloy ingot is pulverized, it is packed into a quartz tube;

[0034] (4) After evacuating the vacuum in the furnace chamber to a high vacuum, fill it with high-purity argon;

[0035] (5) Turn on the power supply of the copper roller, and set the speed range to 20-80m / s;

[0036] (6) The quartz tube is heated, and the melt in the quartz tube is sprayed onto a high-speed rotating copper roller with high-purity argon gas, and a titanium-based amorphous solder foil strip is formed under rapid cooling conditions.

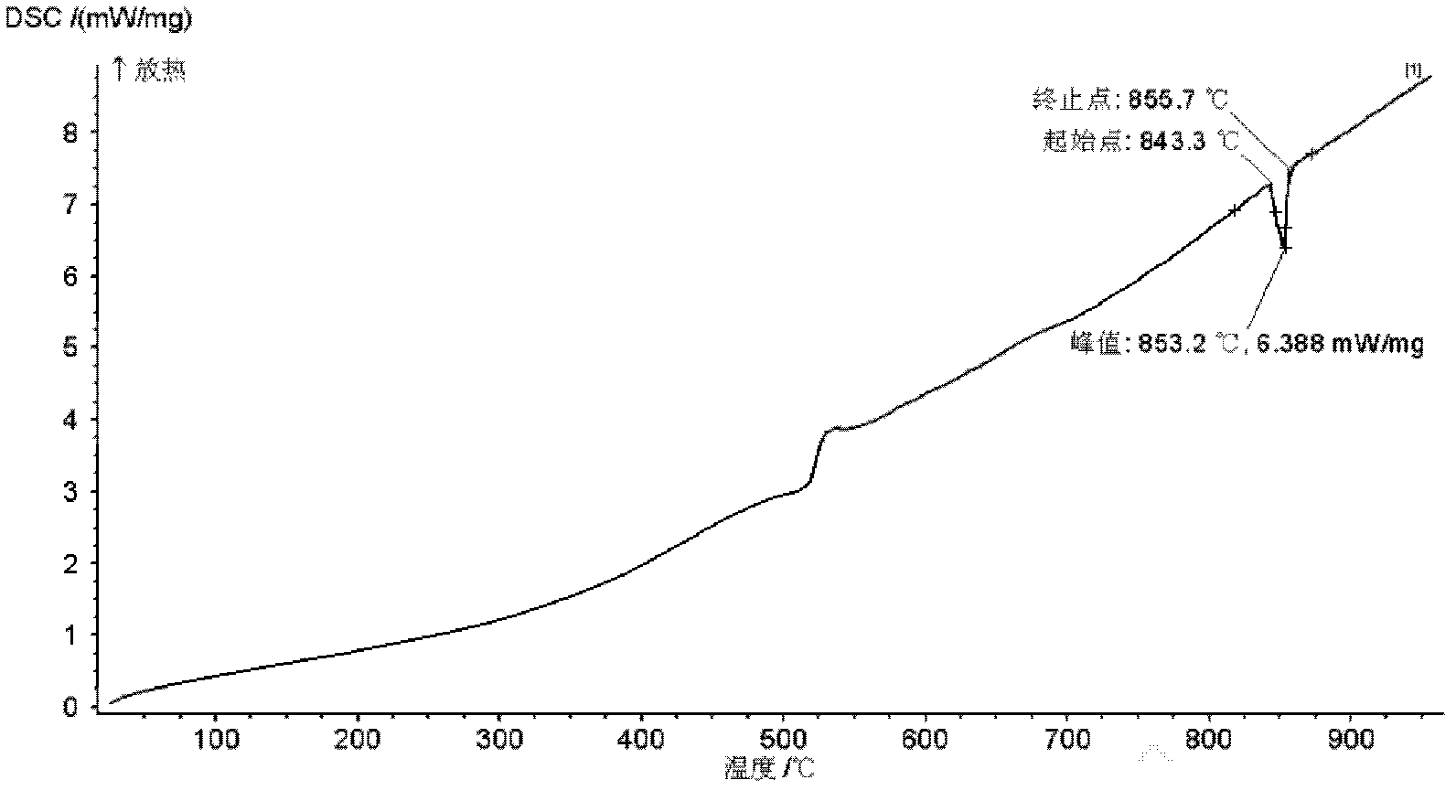

Embodiment 1

[0038] The invention provides a titanium-based amorphous solder foil strip for brazing. The percentages of its components and contents are: Ti: 40%, Zr: 35%, Cu: 13%, Ni: 9.0%, Co: 3.0%.

[0039] The preparation method of the above-mentioned titanium-based amorphous solder foil strip for brazing comprises the following steps:

[0040] (1) Ti, Zr, Cu, Ni and Co are weighed according to the above formula on an electronic balance to prepare ingredients, wherein the purity of Ti, Zr, Cu, Ni and Co is all greater than 99.99%.

[0041] (2) Put the above-mentioned ingredients into a magnetic levitation water-cooled crucible and repeatedly smelt 4 times. Among them, before melting, the inner vacuum of the magnetic levitation water-cooled crucible was evacuated to 2.0×10 -2 Pa, filled with high-purity argon to repeatedly wash the magnetic levitation water-cooled crucible 4 times, and then smelted 4 times under the protection of argon. In order to ensure uniform composition of the sme...

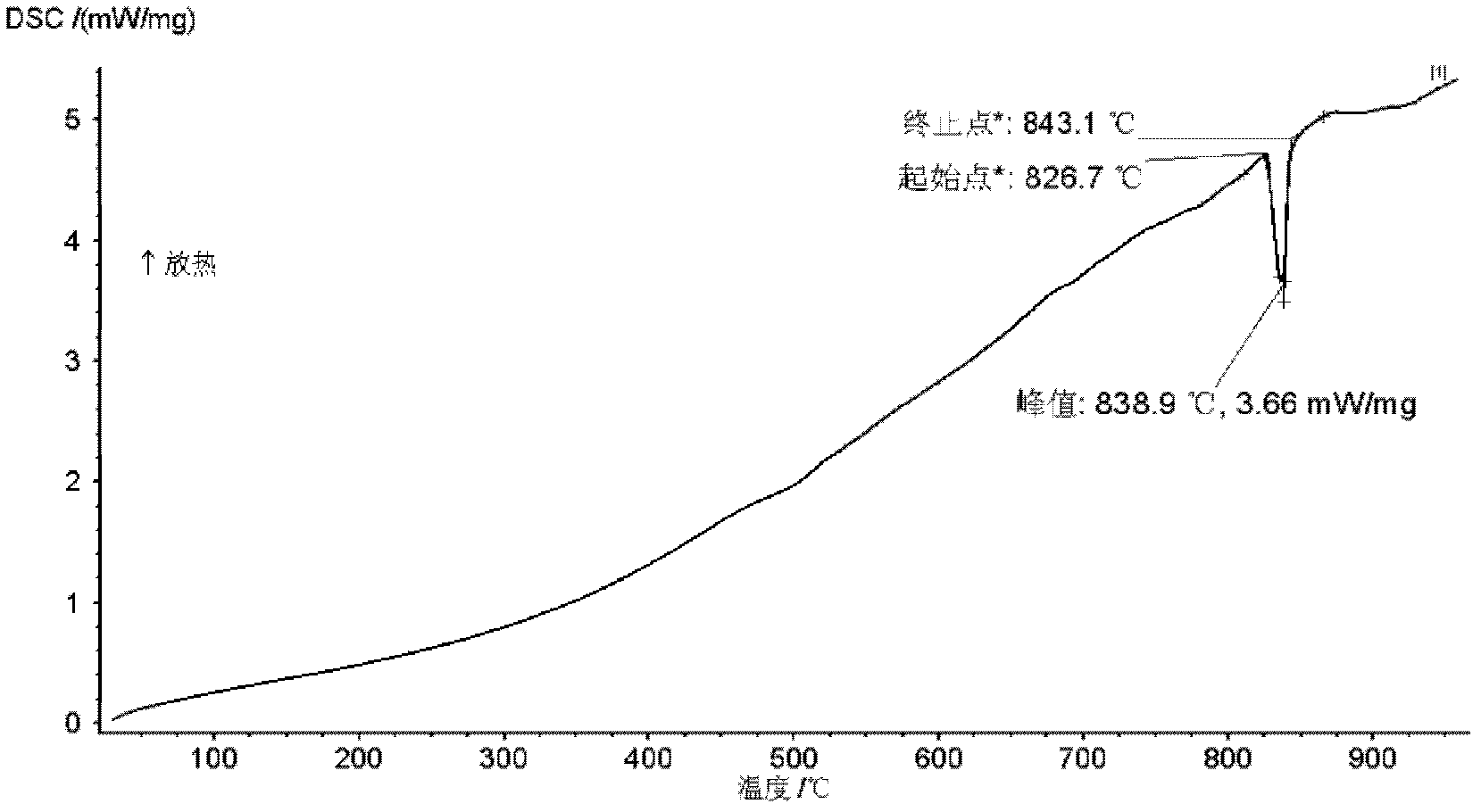

Embodiment 2

[0048] The invention provides a titanium-based amorphous solder foil strip for brazing. The percentages of its components and contents are: Ti: 44.5%, Zr: 30%, Cu: 10%, Ni: 15%, Co: 0.5%.

[0049] The preparation method of the above-mentioned titanium-based amorphous solder foil strip for brazing comprises the following steps:

[0050] (1) Ti, Zr, Cu, Ni and Co are weighed according to the above formula on an electronic balance to prepare ingredients, wherein the purity of Ti, Zr, Cu, Ni and Co is all greater than 99.99%.

[0051] (2) Put the above-mentioned ingredients into a magnetic levitation water-cooled crucible and repeatedly smelt 4 times. Among them, the vacuum in the crucible was evacuated to 2.0×10 before melting. -2 Pa, filled with high-purity argon to wash the crucible 5 times repeatedly, and then smelted under the protection of argon. In order to ensure uniform composition of the smelted solder, electromagnetic stirring is used and the alloy ingot is broken bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com