Poly-guanidine SFT bactericide

A fungicide, polyhexamethylene guanidine technology, applied in biocides, sterilization/microdynamic water/sewage treatment, disinfectants, etc. Excellent bacteriostatic and bactericidal effect, safe transportation and storage, long-lasting effect of sterilization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1, a kind of oilfield reinjection water bactericide is made up of the raw material of following weight ratio, 12 kilograms of polyhexamethyleneguanidine hydrochloride, 3 kilograms of jieeramine, 6 kilograms of polyaminopropyl biguanide, 2 kilograms of guanidine hydrogen chloride, 3 kg of iron sulfate, 25 kg of water.

[0012] The preparation method is as follows: firstly add water, ferric sulfate and jieeramine into the reaction kettle in proportion, stir for 10 hours at a temperature of 100-110°C, cool to normal temperature after the reaction is completed, and then add polyhexamethyleneguanidine, Add polyolefin-based guanidine, then stir and mix evenly.

Embodiment 2

[0013] Embodiment 2, a kind of oilfield reinjection water bactericide, is made up of the raw material of following weight proportion, polyhexamethylene guanidine hydrochloride 10 kilograms, jieeramine 4 kilograms, polyaminopropyl biguanide 5 kilograms, guanidine hydrogen chloride 3 kilograms parts , 2 kg of iron sulfate, 30 kg of water. Preparation method is the same as embodiment 1

Embodiment 3

[0014] Embodiment 3, a kind of oilfield reinjection water bactericide, is made up of the raw material of following weight ratio, polyhexamethylene guanidine hydrochloride 15 kilograms, geeramine 2 kilograms, polyaminopropyl biguanide 7 kilograms, guanidine hydrogen chloride 1 kilogram, 4 kg of iron sulfate, 20 kg of water. The preparation method is the same as in Example 1.

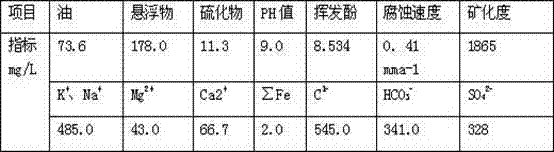

[0015] 1. Comparison of the effects of guanidine fungicides

[0016] Use concentrationmg / l temperature TGB (Saprophytic bacteria) efficiency SRB (Sulphate Reducing Bacteria) efficiency Polyhexamethyleneguanidine Hydrochloride 10 40 2.5X10 7 / ml 80 2.5X10 7 / ml 83 polyaminopropyl biguanide 10 40 2.5X10 7 / ml 76 2.5X10 7 / ml 78 Guanidine Hydrochloride 10 40 2.5X10 7 / ml 75 2.5X10 7 / ml 75 Background technology listed oilfield reinjection water bactericide 10 40 2.5X10 7 / ml 90 2.5X10 7 / ml 90 Example 1 10 40 2.5X10 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com