Method of in situ synthetic steel bond hard alloy casting composite hammerhead and hammerhead

A technology of steel-bonded hard alloy and composite hammer head, which is applied in the direction of grain processing, etc., can solve the problems of complex casting process, hammer head failure, narrow application range, etc., and achieve wear-resistant alloy without falling off, good surface quality and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Weigh 0.5 kg of Ti powder with an average particle size of 5 μm, 0.2 kg of 5 μm graphite powder, 0.2 kg of 3-4.5 μm W powder and 2-20 μm metal powder (Ni: 60% wt, Cr: 5% wt , Cu: 5% wt, B: 3% wt, all the other being Fe) 0.2kg, mixed in ball mill for 4 hours;

[0041] Step 2: Add 50g of polyvinyl alcohol (concentration 8%wt) aqueous solution to the mixed powder, stir and mix to make a powder coating paste;

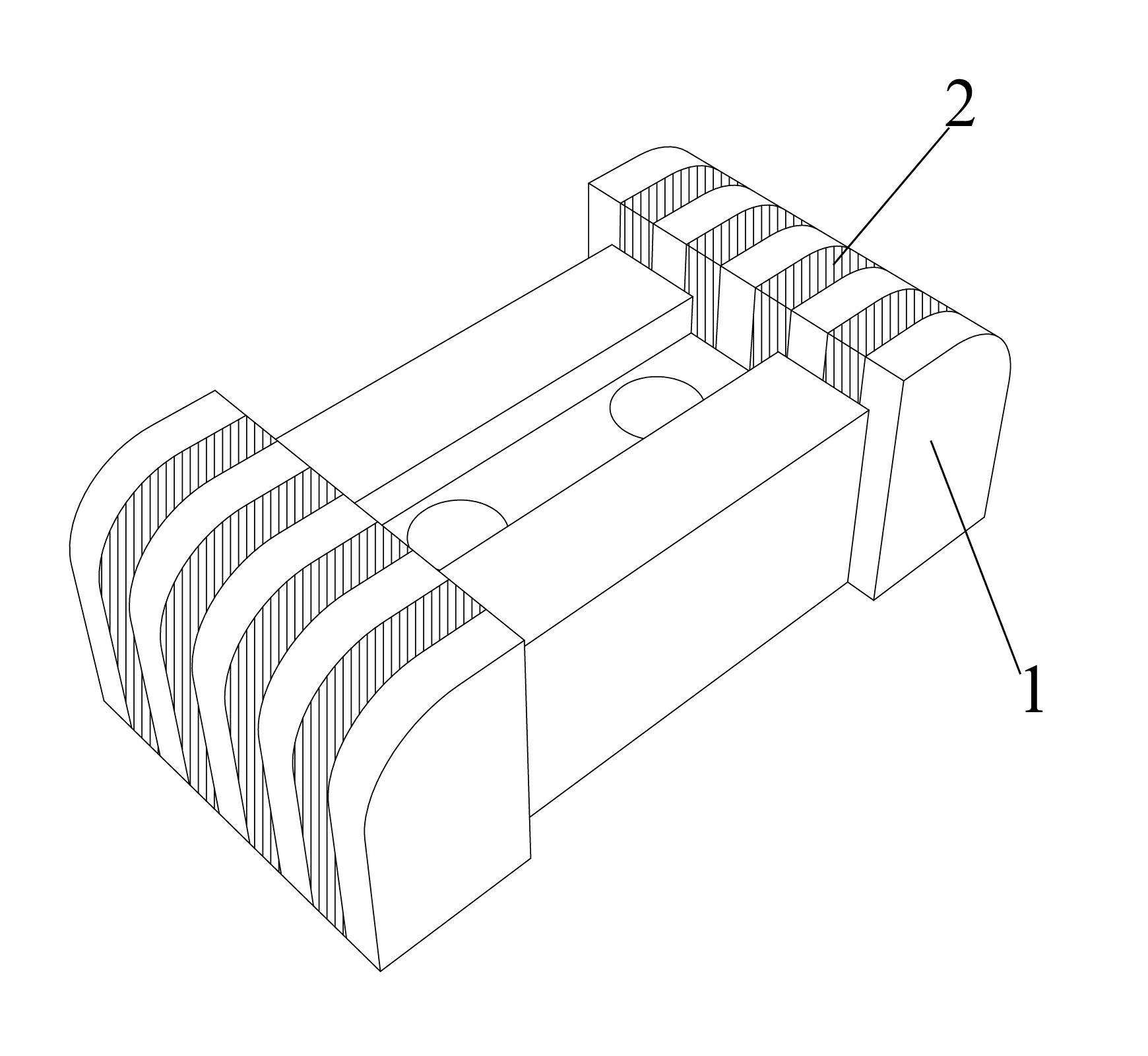

[0042] Step 3: Cut out 5 grooves with a width of 20 mm and a depth of 60 mm in the working part of the EPS foam plastic model prepared in advance, and fill the grooves with powder coating paste;

[0043] Step 4: Hang a magnesia powder anti-sticking sand coating about 2mm thick on the outside, and dry it at 45°C for 36 hours;

[0044]Step 5: Assemble the pouring device, smelt the high-chromium cast iron molten steel and vacuumize it for pouring. The pouring temperature is 1400-1500 ℃ and the vacuum degree is 0.06MPa. During the pouring process, the high tempe...

Embodiment 2

[0047] Step 1: Weigh 0.25 kg of Ti powder with an average particle size of 15 μm, 0.15 kg of graphite powder of 10 μm, 0.1 kg of W powder of 5.5 μm and metal powder of 10-80 μm (Ni: 20% wt, Cr: 30% wt, Cu : 10%wt, the rest is Fe) 0.1kg, mixed in ball mill for 4 hours;

[0048] Step 2: Add 30g of polyvinyl alcohol (concentration 8%wt) aqueous solution to the mixed powder, stir and mix to make a powder coating paste;

[0049] Step 3: Cut out three 15mm wide and 40mm deep grooves in the working part of the EPS foam plastic model of the hammer head casting prepared in advance, and fill the grooves with powder coating paste;

[0050] Step 4: Hang a magnesia powder anti-sticking sand coating about 2mm thick on the outside, and dry it at 45°C for 24 hours;

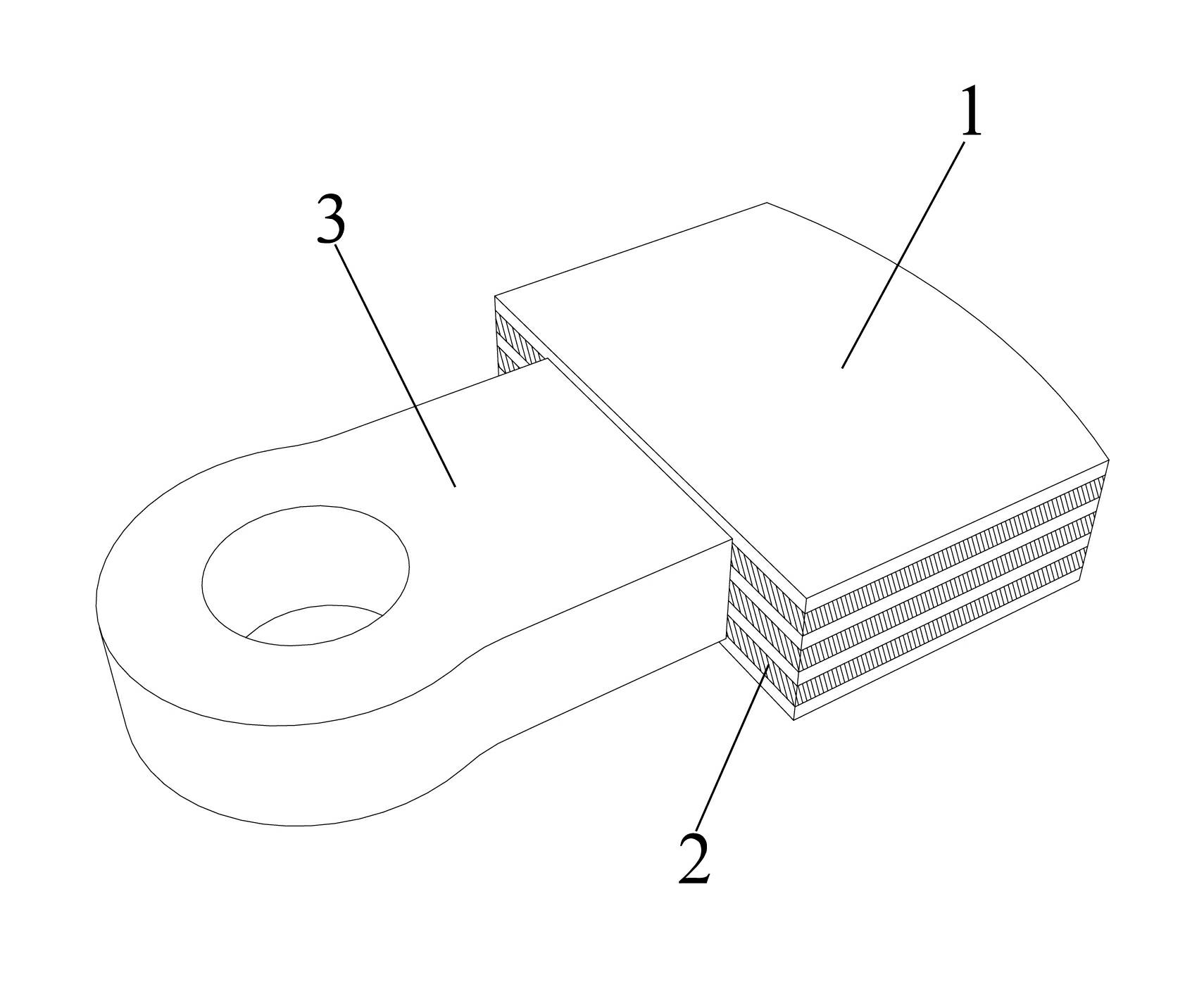

[0051] Step 5: Insert the pre-made carbon steel, alloy steel or high manganese steel hammer handle into the hammer head mold. If necessary, the hammer handle should be treated with hard alloy coating to increase wear resistance;...

Embodiment 3

[0055] Step 1: Weigh 0.1 kg of Ti powder with an average particle size of 20 μm, 0.15 kg of 10 μm graphite powder, 0.6 kg of 2.5 μm W powder and 15-64 μm metal powder (Co: 20% wt, Cr: 20% wt, B : 8%wt, Si: 5%wt, all the other are Fe) 0.1kg, mix 4 hours in ball mill;

[0056] Step 2: Add 30g of polyvinyl alcohol (concentration 8%wt) aqueous solution to the mixed powder, stir and mix to make a powder coating paste;

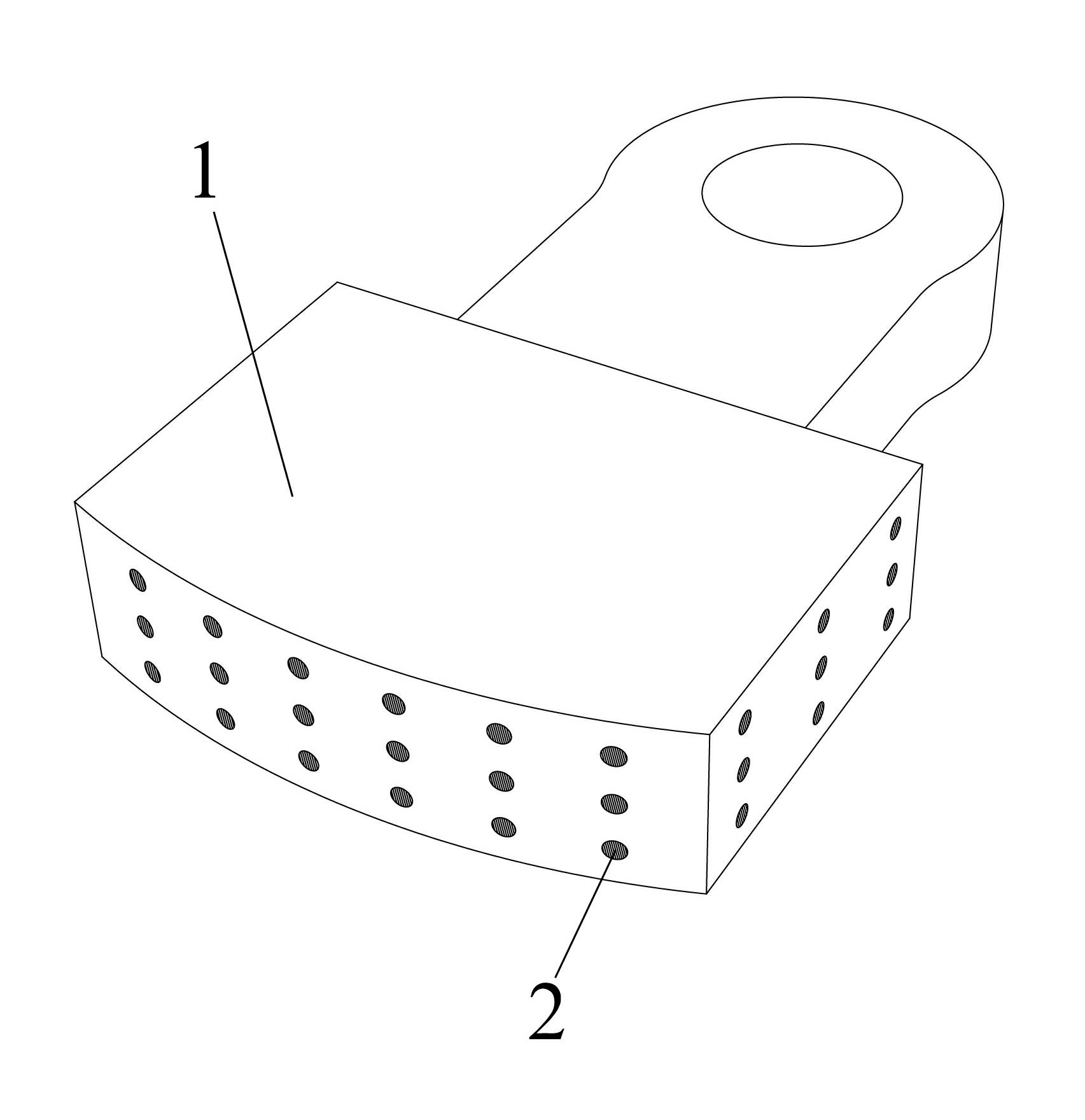

[0057] Step 3: Drill densely distributed ¢10-¢20 mm holes on both sides and the bottom surface of the working part of the EPS foam plastic model prepared in advance, and the hole depth is 15-40 mm, and fill the powder coating paste in the holes;

[0058] Step 4: Hang a magnesia powder anti-sticking sand coating about 2mm thick on the outside, and dry it at 45°C for 48 hours;

[0059] Step 5: Assemble the pouring device, smelt the molten Mn13 high manganese steel and vacuumize it for pouring. The pouring temperature is 1400-1500°C and the vacuum degree is 0.06MPa. D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com