Preparation method of additive applied in addition type liquid silicone rubber

A liquid silicone rubber and additive technology, applied in the chemical industry, can solve problems such as platinum catalyst poisoning, and achieve the effect of improving performance, good compatibility, and improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

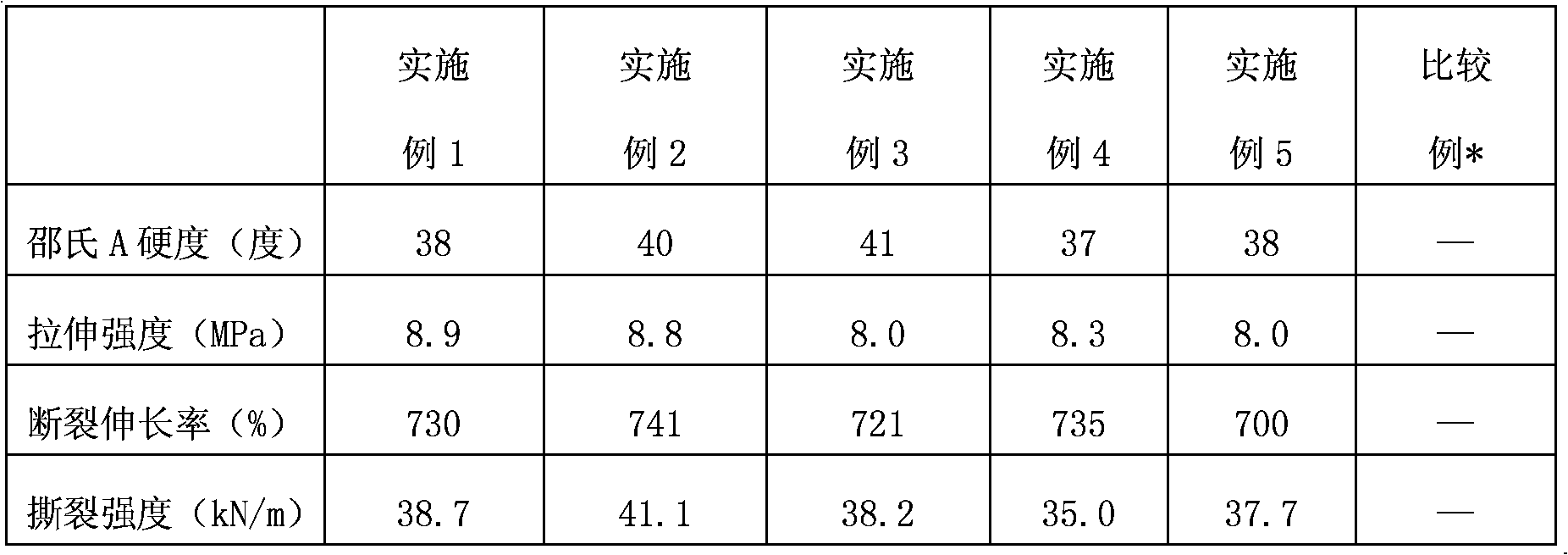

Examples

Embodiment 1

[0018] Mix 100 parts of raw rubber and 30 parts of fumed silica in a kneader to obtain a silicone rubber base material, add 60 parts of benzotriazole to the 100 parts of the base material and mix evenly, add 0.3 parts of 2,5 Methyl 2,5-bis(tert-butylperoxy)hexane was mixed evenly, and pressurized and vulcanized at 170°C for 10 minutes to obtain silicone rubber with benzotriazole added, which was mechanically crushed to obtain silicone rubber micropowder, which was washed with ethanol The silicone rubber micropowder is cleaned to obtain an additive for encapsulating benzotriazole in silicone rubber.

Embodiment 2

[0020] Dissolve 100 parts of phenyl silicone resin with a softening point of 180°C and 100 parts of benzotriazole in toluene to make a solution, pass the solution through a sharp hole, and spray it into a heated spray dryer to obtain a fine powder, which is immersed in stirring and cleaning in ethanol to remove the benzotriazole on the surface of the micropowder, and drying in the air to obtain an additive for encapsulating the benzotriazole with silicone resin.

Embodiment 3

[0022] 4.0g of sodium lauryl sulfate and 200ml of water were stirred and heated to dissolve to obtain a transparent solution, and moved into a flask equipped with a thermometer, a reflux condenser, and a stirrer, stirred, and heated under N 2 Under protection, the temperature was raised to 70°C. Dissolve 25g of benzotriazole in an appropriate amount of isopropanol to prepare a solution, slowly add it to the flask, dissolve 0.5g of potassium persulfate in 2g of 5 styrene monomer, and add it to the reaction system by gradually dropping. React for 4 hours, heat up to 90°C and react for 0.5h, stop the reaction and cool down, add magnesium sulfate aqueous solution to break the emulsion, wash repeatedly with absolute ethanol and distilled water, filter with suction, and obtain polystyrene-encapsulated benzotriazole after vacuum drying at 80°C additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com