Samarium-ferrite radar absorbing material and preparation method thereof

A technology of radar absorbing materials and oxygen bodies, applied in the field of radar absorbing materials, can solve the problems of restricting the industrialized mass production of materials, unfavorable practical application, complicated process flow, etc. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

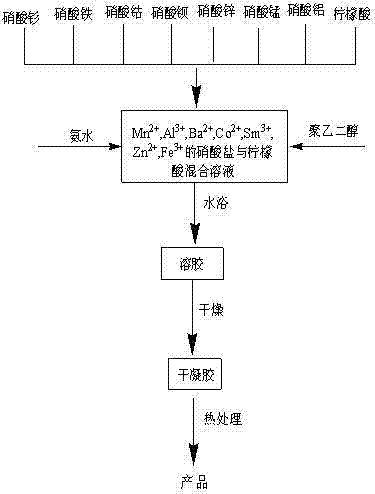

Method used

Image

Examples

Embodiment 1

[0032] A. Raw material preparation: according to the molecular formula BaMn 0.4 Zn 0.4 Al 0.2 CoFe 16 o 27 The stoichiometric ratio of each metal nitrate Ba (NO 3 ) 2 , Co (NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 9H 2 O, Mn (NO 3 ) 2 , Zn (NO 3 ) 2 ·6H 2 O, Al (NO 3 ) 3 9H 2 0, simultaneously take citric acid by citric acid / metal ion total molar number=0.6:1, dissolve metal nitrate and citric acid respectively with deionized water, obtain reddish-brown clear solution and colorless transparent solution respectively, add simultaneously The molar ratio of ethylene glycol / citric acid=0.6 Add polyethylene glycol, adjust the pH to 4 with ammonia water, and the solution is dark reddish brown at this time;

[0033] B. Dry gel preparation: put the solution in step A under electric stirring, slowly concentrate in a 50°C water bath for 12 hours, then move to a 100°C oven and continue drying for 40 hours until a black fluffy dry gel is formed;

[0034] C. Heat treatment proc...

Embodiment 2

[0037] A. Raw material preparation: according to the molecular formula BaMn 0.4 Zn 0.4 Al 0.2 CoFe 16 o 27 The stoichiometric ratio of each metal nitrate Ba (NO 3 ) 2 , Co (NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 9H 2 O, Mn (NO 3 ) 2 , Zn (NO 3 ) 2 ·6H 2 O, Al (NO 3 ) 3 9H 20, simultaneously take citric acid by citric acid / metal ion total molar number=0.8:1, dissolve metal nitrate and citric acid respectively with deionized water, obtain reddish-brown clear solution and colorless transparent solution respectively, add simultaneously The molar ratio of ethylene glycol / citric acid=0.8 Add polyethylene glycol, adjust the pH to 5 with ammonia water, and the solution is dark reddish brown at this time;

[0038] B. Preparation of xerogel: Place the solution in step A under electric stirring, slowly concentrate in a 55°C water bath for 11.5h, then move to an oven at 105°C and continue drying for 38h until a black fluffy xerogel is formed;

[0039] C. Heat treatment proc...

Embodiment 3

[0041] A. Raw material preparation: according to molecular formula Ba 0.9 SM 0.1 mn 0.4 Zn 0.4 Al 0.2 CoFe 16 o 27 The stoichiometric ratio of each metal nitrate Ba (NO 3 ) 2 , Co (NO 3 ) 2 ·6H 2 O and Fe (NO 3 ) 3 9H 2 O, Mn (NO 3 ) 2 , Zn (NO 3 ) 2 ·6H 2 O, Al (NO 3 ) 3 9H 2 O and Sm (NO 3 ) 3 ·6H 2 O, add SiO 2 0.2%wt, CaO0.2%wt, MgO0.5%wt, weigh citric acid according to citric acid / metal ion total molar number=1:1 simultaneously, dissolve metal nitrate and citric acid respectively with deionized water, obtain respectively Reddish-brown solution and colorless transparent solution, add polyethylene glycol at the same time according to the molar ratio of polyethylene glycol / citric acid = 1, adjust the pH to 6 with ammonia water, and the solution is dark reddish-brown at this time;

[0042] B. Preparation of xerogel: Place the solution in step A under electric stirring, slowly concentrate in a water bath at 60°C for 11 hours, then move to an oven at 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com