Cluster fiber thermoplastic composite sheet material

A composite sheet, thermoplastic technology, used in textiles and papermaking, non-woven fabrics, layered products, etc., can solve the large difference in the ratio of longitudinal and lateral strength of the sheet, the effect of lightweight material reduction is not significant, and the fibers are not in all directions. The problem of homogeneity, etc., achieves the effect of small vertical and horizontal strength ratio, light weight and low density of the plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

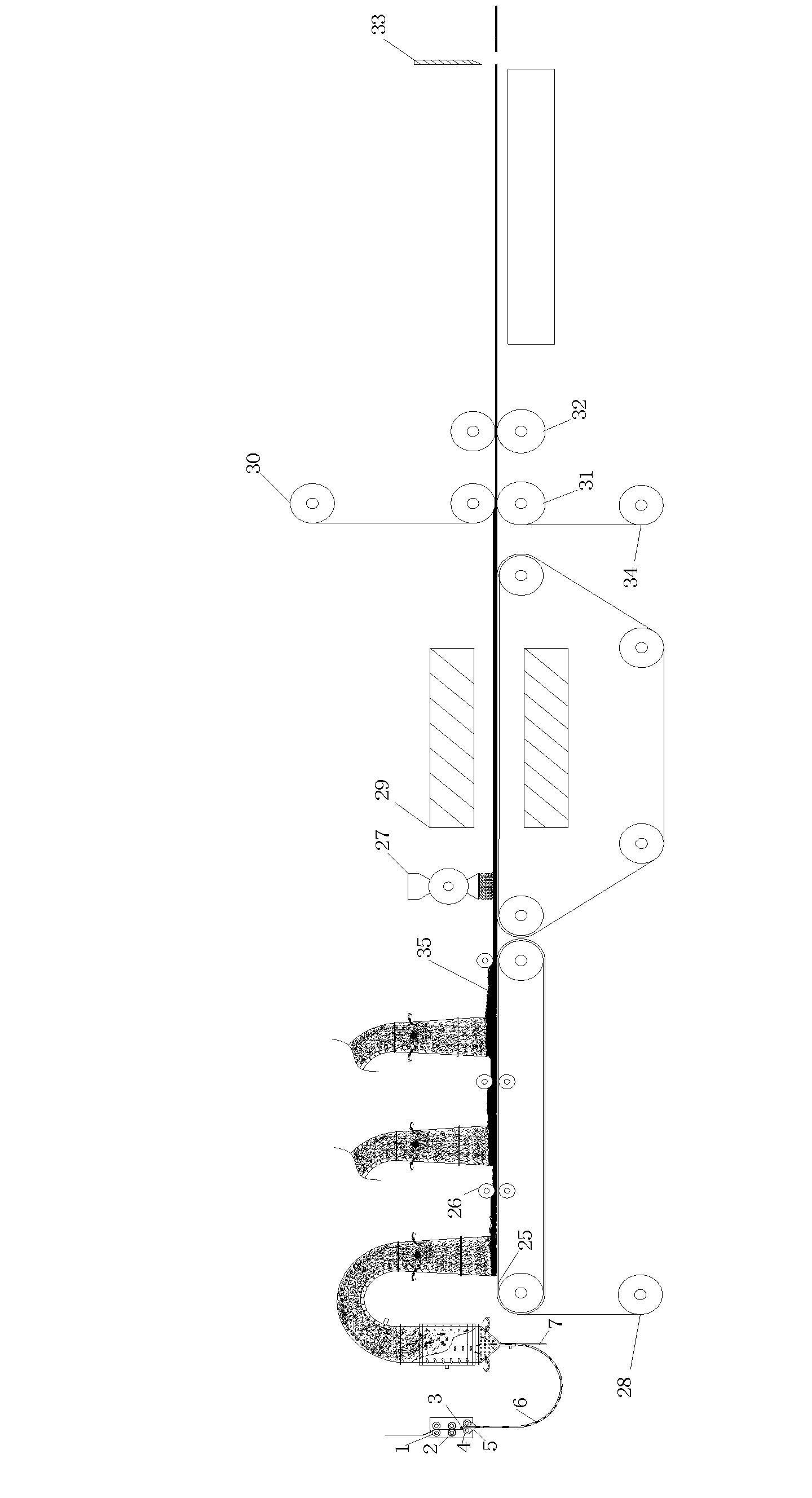

Method used

Image

Examples

Embodiment 1

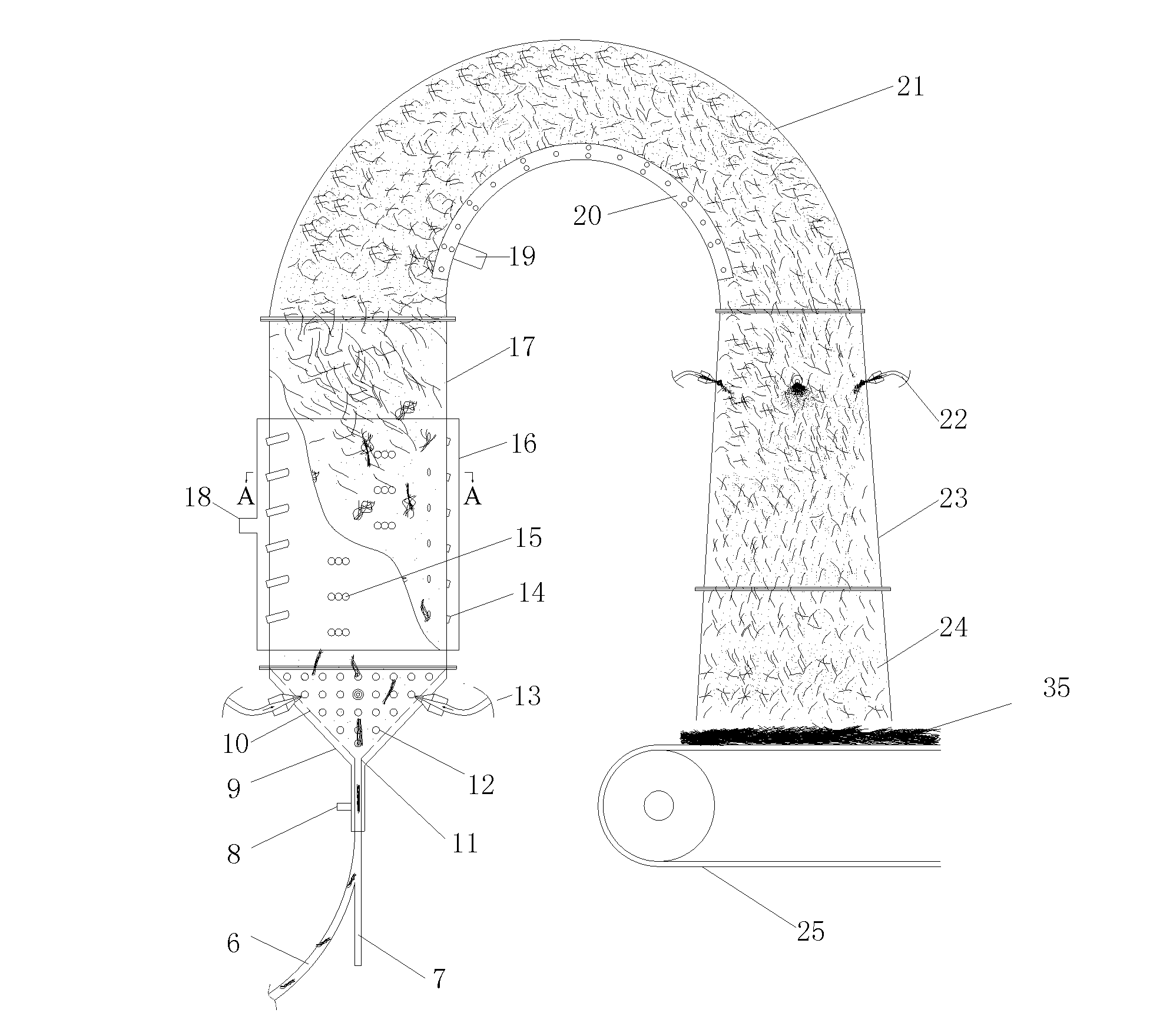

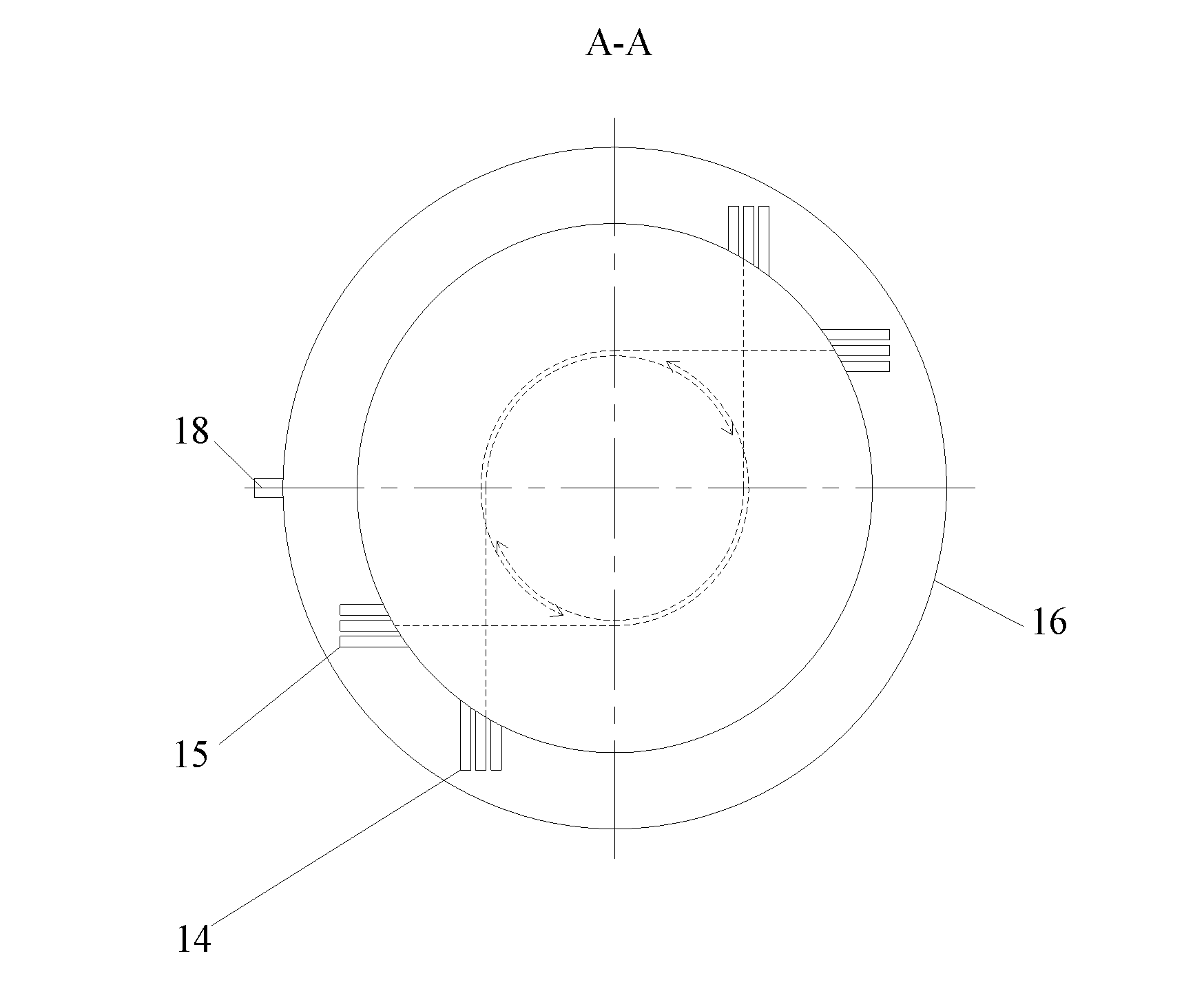

[0039] The diameter of the pneumatic dispersing and mixing chamber 17 is 800 mm, the diameter of the conveying pipe 6 is Ф20 mm, the diameter of the rising dispersed airflow nozzle 12 is Ф15 mm, the diameters of the clockwise side stirring and cutting air nozzle 14 and the counterclockwise side stirring and cutting air nozzle 15 are equal. It is Ф10mm.

[0040] Raw materials: E-glass fiber 2400tex (twisted roving, density 2.35g / cm 3 , diameter 13μm), the shear length of glass fiber bundles is 50-75mm, 145#PP powder (density 0.91g / cm 3 , 80 mesh), the glue surface is 55g / ㎡ of PP film, and the non-woven fabric is 100g / ㎡ of spunlace non-woven fabric compounded with PE glue surface (of which 45g / ㎡ of PE film and 55g / ㎡ of PET spunlace non-woven fabric) .

[0041] The velocity of the glass fiber conveying airflow is 4m / s, the velocity of the ascending dispersed airflow is 3m / s, and the velocity of the lateral stirring and cutting airflow is 2.0m / s.

[0042] The uniform base mat m...

Embodiment 2

[0044] The diameter of the pneumatic dispersing and mixing chamber 17 is 600mm, the diameter of the conveying pipe 6 is Ф18mm, the diameter of the rising dispersed airflow nozzle 12 is Ф15mm, the diameters of the clockwise side stirring and cutting airflow nozzle 14 and the counterclockwise side stirring and cutting airflow nozzle 15 are equal. It is Ф10mm.

[0045] Raw materials: E-glass fiber 2400tex (twisted roving, density 2.35g / cm 3 , diameter 13μm), the shear length of glass fiber bundles is 50-75mm, 145#PP powder (density 0.91g / cm 3 , 80 mesh), polyethylene (PE) powder (density 0.95g / cm 3 , 60 mesh), the rubber surface adopts PP film 55g / ㎡, and the non-woven fabric adopts needle-punched non-woven fabric 80g / ㎡.

[0046] The velocity of the glass fiber conveying airflow is 5m / s, the velocity of the ascending dispersed airflow is 4m / s, and the velocity of the lateral stirring and cutting airflow is 3m / s.

[0047] The uniform base mat made of disordered and three-dimensi...

Embodiment 3

[0049] The diameter of the pneumatic dispersing and mixing chamber 17 is 500mm, the diameter of the glass fiber conveying pipe is Ф25mm, the diameter of the rising dispersed airflow nozzle 12 is Ф15mm, the clockwise side stirring and cutting airflow nozzle 14 and the counterclockwise side stirring and cutting airflow nozzle 15 The diameters are Ф8mm.

[0050] Raw materials: E-glass fiber 2400tex (twisted roving, density 2.35g / cm 3 , diameter 13μm), the shear length of glass fiber bundles is 70-75mm, 145#PP powder (density 0.91g / cm3, 80 mesh), polyethylene (PE) powder (density 0.95g / cm 3 , 60 mesh), the rubber surface adopts PP film 55g / ㎡, and the non-woven fabric adopts needle-punched non-woven fabric 80g / ㎡.

[0051] The velocity of the glass fiber conveying airflow is 3.5m / s, the velocity of the ascending dispersed airflow is 3m / s, and the velocity of the lateral stirring and cutting airflow is 2.5m / s.

[0052] The uniform base mat made of disordered and three-dimensional a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com