Cutting tool

A technology of cutting tools and sipes, which is applied to milling cutting blades, tools for lathes, milling cutters, etc., can solve problems such as overlapping of difficult positioning surfaces, deformation of fasteners, vibration of blades, etc., and improve the quality of the processed surface , Reduce blade deformation and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

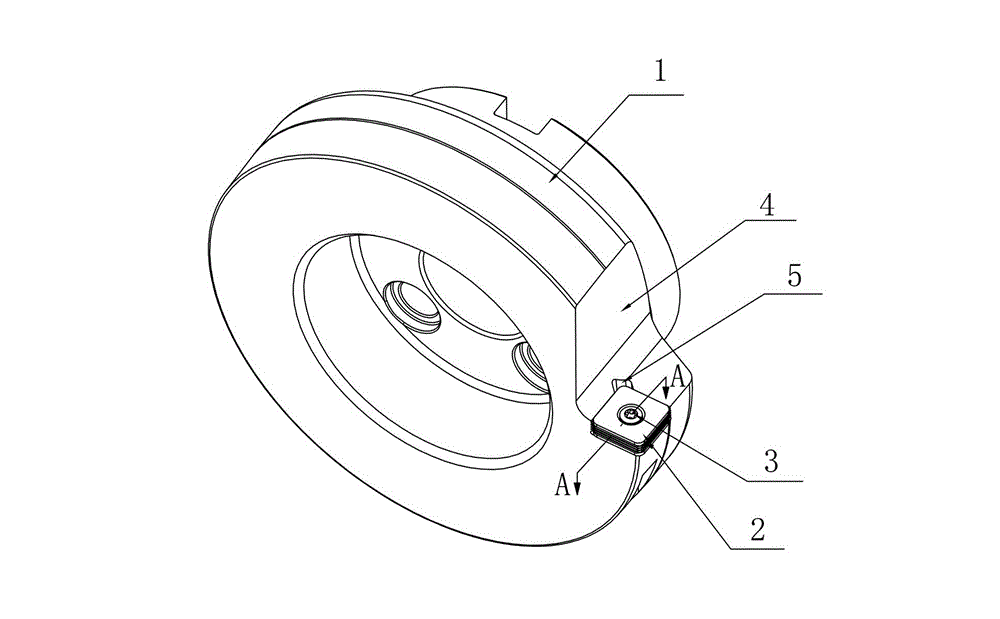

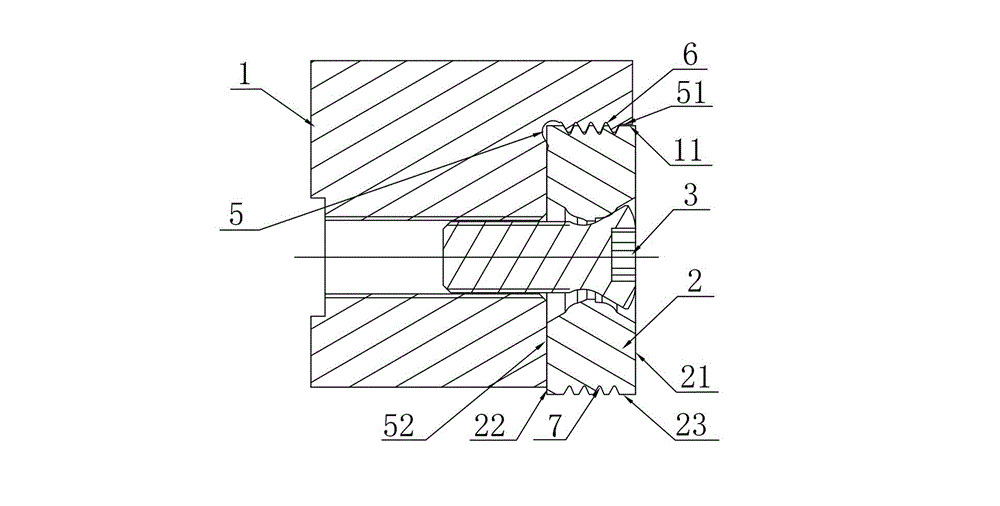

[0023] Figure 1 to Figure 3 A rotary cutting tool embodiment of the present invention is shown, the cutting tool includes a cutter body 1, a blade 2 and a fastener 3, the cutter body 1 is a cylindrical cutter body with its own central axis as the center of rotation, the cutter Body 1 is provided with a set of chip flutes 4 and sipes 5, cutter body 1 fixes blade 2 in sipes 5 through fasteners 3, sipes 5 are composed of sipes side 51 and sipes bottom 52, blade 2 It consists of an upper bottom surface 21, a lower bottom surface 22, and a side surface 23 connecting the upper bottom surface 21 and the lower bottom surface 22. There is an unevenness between the side surface 23 of the blade 2 and the side surface 51 of the sipe, which can prevent the side surface 23 from being inclined outward relative to the side surface 51 of the sipe. The matching structure makes the connection between the cutter body 1 and the blade 2 more compact and reliable. During the cutting process, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com