Semiconductor memory device and manufacturing method of the same

A technology of memory elements and semiconductors, applied in semiconductor devices, static memory, electric solid state devices, etc., can solve the problems of reducing tunneling magnetoresistance and achieve the effect of reducing write current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

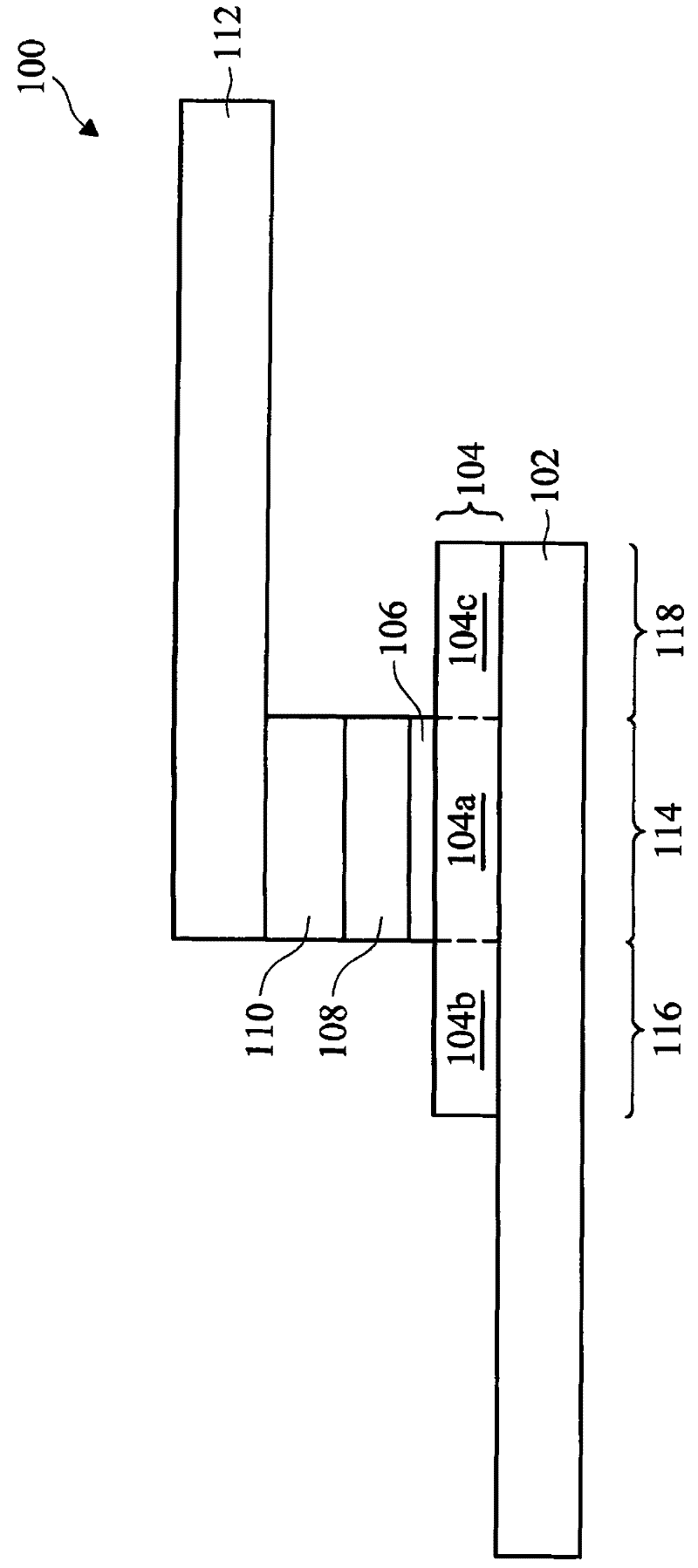

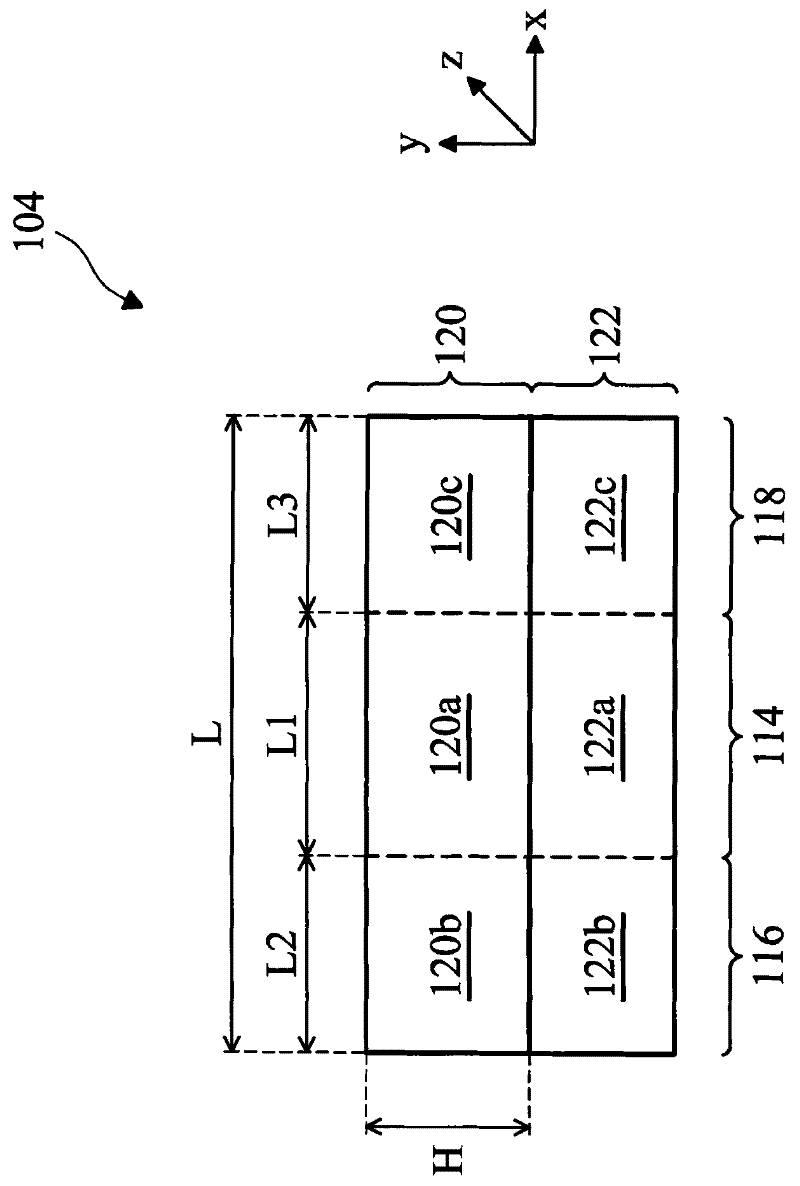

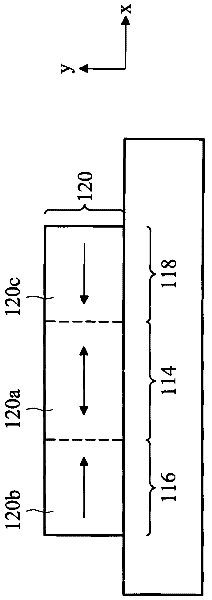

[0080] figure 1 It is a cross-sectional view showing a semiconductor memory device 100 constructed according to an embodiment disclosed in the present invention. Please refer to figure 1 ,this Figure 1 Also, the semiconductor memory element 100 and its manufacturing method will be described. The semiconductor memory device 100 is part of a spin torque transfer magnetic random access memory (STT-MRAM). In one embodiment, the semiconductor memory device 100 includes a stack formed of a plurality of material layers, which functions as a magnetic tunnel junction (MTJ), and according to various disclosed embodiments of the present invention There are different configurations.

[0081] The semiconductor memory device 100 is formed on a semiconductor substrate, such as a silicon substrate or other suitable semiconductor substrates. The semiconductor memory device 100 includes a first electrode (or bottom electrode) 102, wherein the first electrode is formed of a conductive mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com