Electrically rewritable non-volatile memory element and method of manufacturing the same

A non-volatile storage and component technology, used in electrical components, semiconductor/solid-state device manufacturing, information storage, etc., can solve the problems of recording layer damage, inability to apply electrode protective film, low thermal efficiency, etc., and achieve the effect of reducing the amount of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Now, preferred embodiments of the present invention will be explained in detail with reference to the drawings.

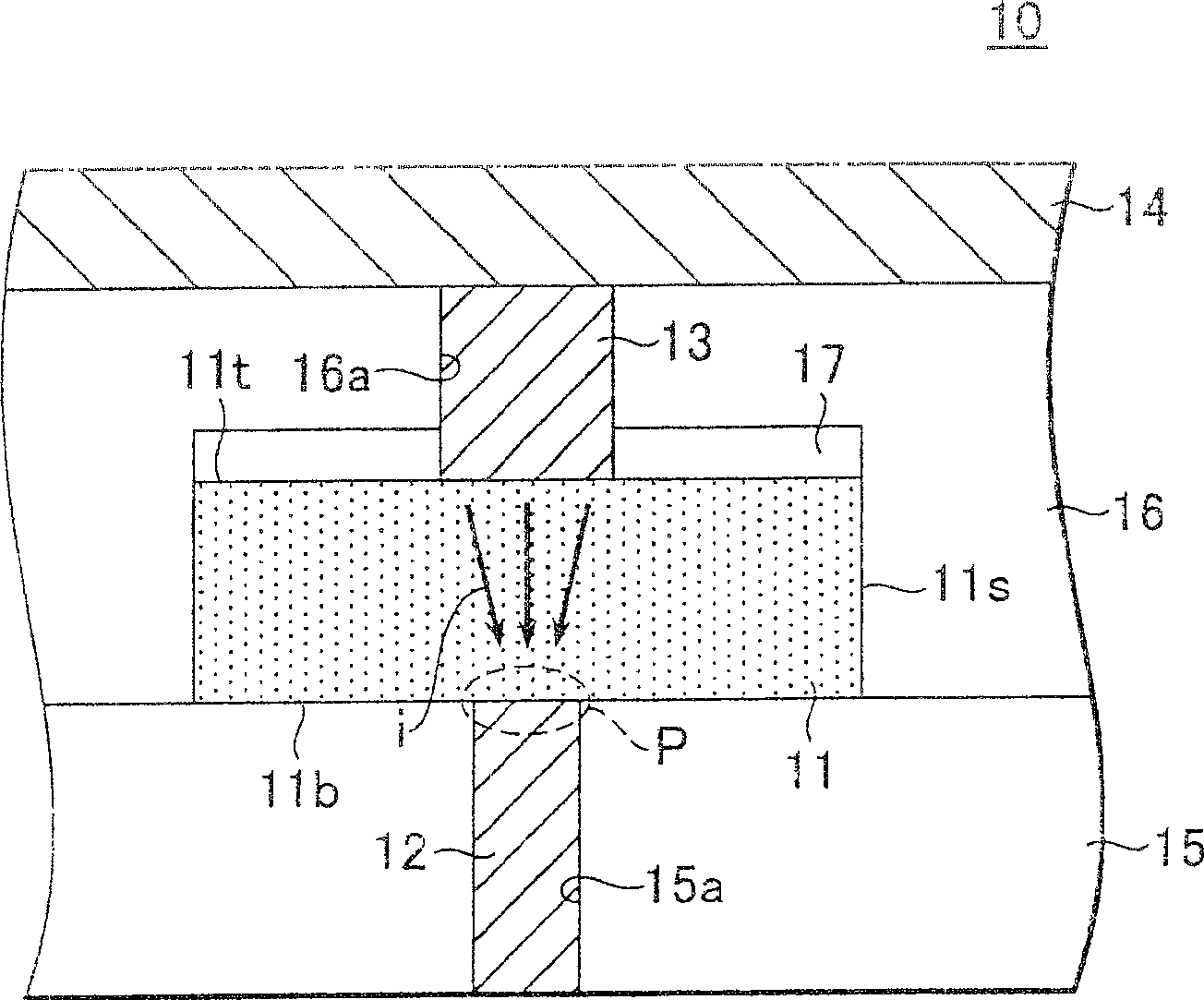

[0056] figure 1 It is a schematic cross-sectional view of the structure of the nonvolatile memory element 10 according to the first preferred embodiment of the present invention.

[0057] Such as figure 1 As shown, the nonvolatile memory element 10 according to the present invention is provided with: a recording layer 11, which includes a phase change material; a lower electrode 12, which is provided in contact with the lower surface 11b of the recording layer 11; and an upper electrode 13 which is in contact with The upper surface 11 t of the recording layer 11 is provided in contact; and the bit line 14 is a metal layer provided on the upper electrode 13.

[0058] The lower electrode 12 is embedded in the through hole 15 a provided to the first interlayer insulating film 15. Such as figure 1 As shown, the lower electrode 12 is in contact with the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com