Method for improving upper critical field and critical current density of iron-based superconductor

A critical current density and iron-based superconductor technology, which is applied in the usage of superconductor elements, the manufacture/processing of superconductor devices, superconducting devices, etc., can solve the problem of low critical current density of iron-based superconductors, and improve the irreversible field and Effects of critical current density, improvement of grain connectivity, and improvement of superconducting grain connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

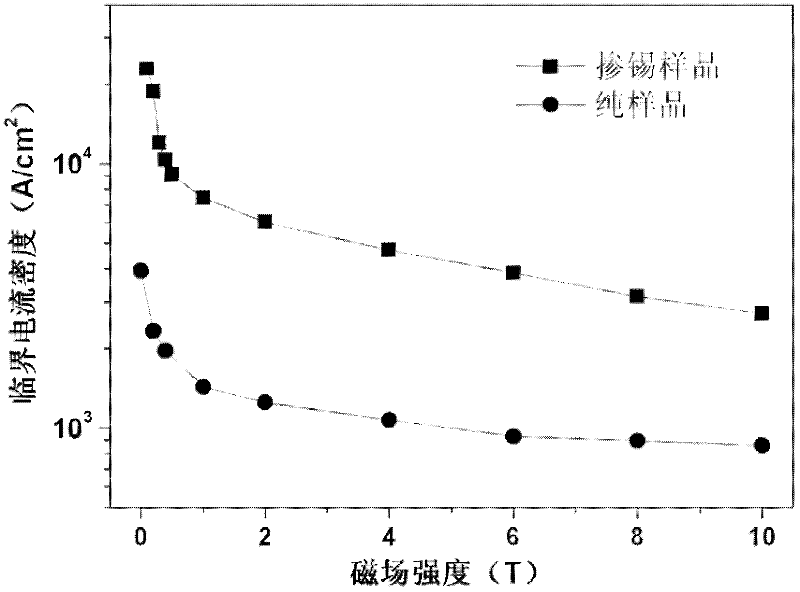

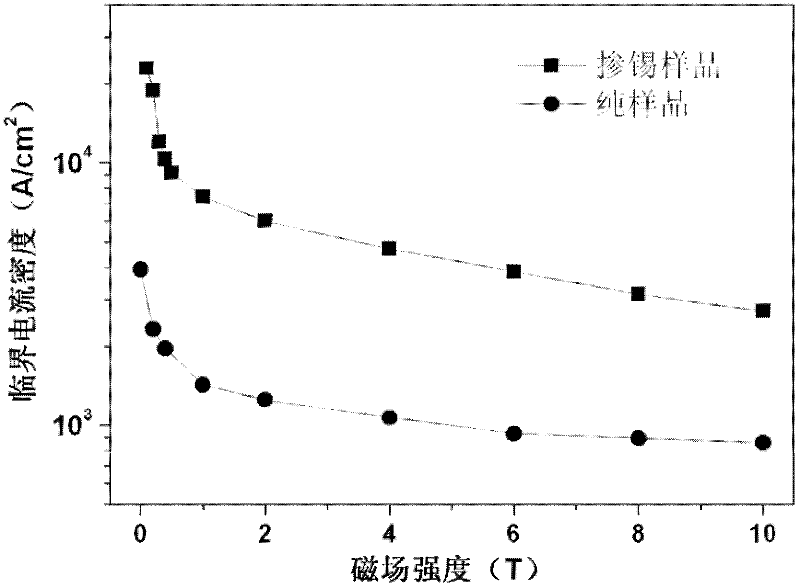

[0013] In an argon atmosphere glove box, put Ba chips, K blocks, Fe powder, and As powder according to the chemical formula Ba 0.5 K 0.5 Fe 2 As 2 For the molar ratio shown, weigh 1.963 grams of Ba, 0.559 grams of K, 3.193 grams of Fe, and 4.284 grams of As, and mix thoroughly and uniformly to obtain a precursor powder. Then add a mass ratio of Sn:Ba to the precursor powder 0.5 K 0.5 Fe 2 As 2 = 0.01:1 tin powder, after grinding and mixing evenly again, put the Sn-added precursor powder into the abrasive tool and press it into a block, put it into a quartz tube, vacuumize the quartz tube and seal it. Put the sealed quartz tube in an annealing furnace, keep it at 500°C for 0.5 hours, and then raise the temperature to 1100°C for 0.5 hours. After the furnace is cooled to room temperature, the magnetism and resistance of the sample are measured by a comprehensive physical property measurement system (PPMS-9, manufactured by Qunatum Design Company of the United States), and ...

Embodiment 2

[0015] In an argon atmosphere glove box, the solid-state reaction method sintered Ba 0.6 K 0.4 Fe 2 As 2 Weigh 5 grams, grind evenly, and then add a mass ratio of Sn: Ba 0.6 K 0.4 Fe 2 As 2 = 0.05:1 tin powder, grind and mix evenly again, put the mixed powder into a 10cm long iron tube, the inner diameter of the tube is 5mm, the outer diameter is 7mm, so that the powder is full and compact in the tube, and then the iron tube is sealed. tube ends. Place the sealed iron tube in the annealing furnace, fill it with high-purity argon after vacuuming, and raise the temperature to 1000°C for 5 hours. After the furnace is cooled to room temperature, the magnetism and resistance of the sample are measured by a comprehensive physical property measurement system (PPMS-9, manufactured by Qunatum Design Company of the United States), and the magnetization critical current density can be obtained greater than 15000A / cm 2 (4.2K, 0T), Ba with an irreversible field greater than 10T (30...

Embodiment 3

[0017] In an argon atmosphere glove box, put Ba chips, K blocks, and FeAs powder according to the chemical formula Ba 0.7 K 0.3 Fe 2 As 2 For the molar ratio shown, weigh 2.602 grams of Ba, 0.318 grams of K, and 7.080 grams of FeAs, and mix them thoroughly and uniformly to obtain the precursor powder. Then add a mass ratio of Sn:Ba to the precursor powder 0.7 K 0.3 Fe 2 As 2 = 0.1:1 tin powder, after re-grinding and mixing evenly, put the mixed powder into an 8cm long niobium tube with an inner diameter of 8mm and an outer diameter of 10mm, so that the powder is full and compact in the tube, and then closed Niobium tube ends. Put the sealed niobium tube in an annealing furnace, vacuumize it, keep it at 500°C for 10 hours, then raise the temperature to 900°C for 20 hours. After the furnace is cooled to room temperature, the magnetism and resistance of the sample are measured by a comprehensive physical property measurement system (PPMS-9, manufactured by Qunatum Design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com