Electroplating pretreatment method for acrylonitrile butadiene styrene (ABS) plastic surface

A pre-treatment technology for ABS plastics and electroplating, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., can solve the problems of complex processing process, high price, adverse effects on operators and the environment, and achieve simple process , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

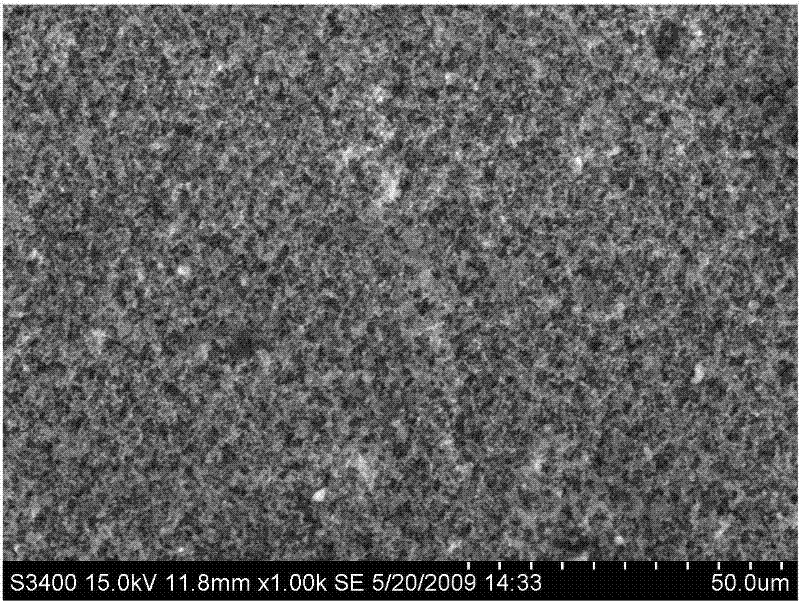

[0056] (4) The chromic acid system is used for roughening, the purpose of which is to increase the microscopic roughness, contact area and hydrophilic ability of the surface of the part, so as to ensure good adhesion of the coating, which is the key process to determine the adhesion of the coating. There are many methods of roughening, and the most widely used is the chromic acid system, which has fast roughening speed and good coating adhesion. Process conditions: 400 g / L CrO 3 , 350mL / L H 2 SO 4 , temperature 65 ℃, time 50 min.

[0057] (5) Neutralization treatment: After chemical roughening treatment, the microporous structure on the surface of plastic parts contains some hexavalent chromium and other impurities. If the cleaning is not thorough, it will affect the bonding force between the plastic and the coating and pollute the plating solution. For this reason, the following process was used for neutralization treatment: 100 g / L NaOH solution, the temperature was room...

Embodiment 2

[0067] (4) Coarsening adopts chromic acid system, process conditions: 400 g / L CrO 3 , 350mL / L H 2 SO 4 , temperature 75 ℃, time 70 min.

[0068] (5) Neutralization treatment: process conditions: 100 g / L NaOH solution, the temperature is room temperature, and the time is 5 minutes.

[0069] (6) Chemical activation: activation solution formula: nickel sulfate concentration 12g / L, sodium hypophosphite concentration 25g / L, stabilizer sodium citrate concentration 8g / L, pH=11, temperature 75°C. The activation method is as follows: dissolve nickel sulfate in sodium citrate solution, then add sodium hypophosphite solution, and then adjust the pH value with dilute ammonia water with a volume fraction of 20%. When activating, put the plastic substrate into the solution and use a constant temperature water bath to After heating up to 75°C, carry out constant temperature treatment at this temperature for 10 minutes.

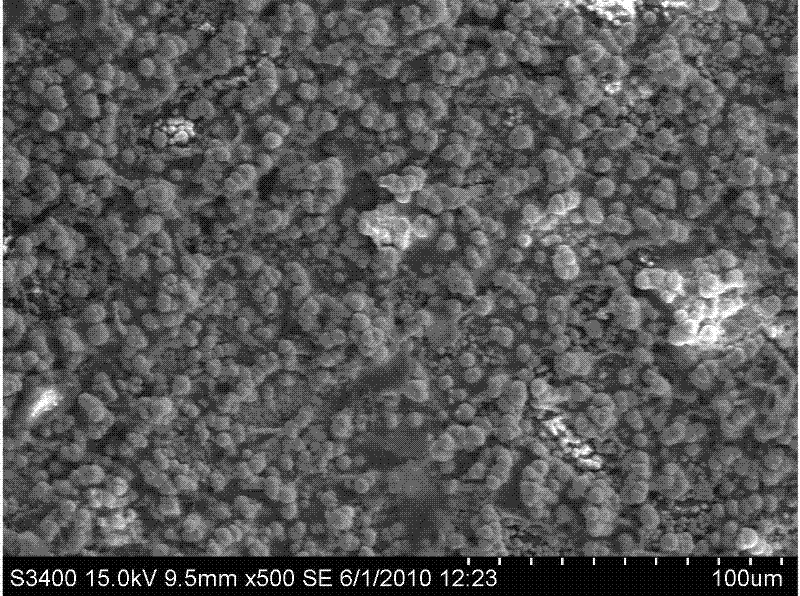

[0070] The plastic after electroplating pretreatment is observed u...

Embodiment 3

[0078] (4) Coarsening adopts chromic acid system, process conditions: 400 g / L CrO 3 , 350mL / L H 2 SO 4 , temperature 70 ℃, time 60 min.

[0079] (5) Neutralization treatment: process conditions: 100 g / L NaOH solution, room temperature, 4 minutes.

[0080] (6) Chemical activation: activation solution formula: nickel sulfate concentration 11g / L, sodium hypophosphite concentration 22g / L, stabilizer sodium citrate concentration 7g / L, pH=10, temperature 73°C. The activation method is as follows: dissolve nickel sulfate in sodium citrate solution, then add sodium hypophosphite solution, and then adjust the pH value with dilute ammonia water with a volume fraction of 20%. When activating, put the plastic substrate into the solution and use a constant temperature water bath to After the temperature was raised to 73°C, a constant temperature treatment was carried out at this temperature for 20 minutes.

[0081] The plastic after electroplating pretreatment is observed under a scan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com