Simplified CeO2/LaZrO3 composite separating layer used for second generation high temperature superconductive tapes and its preparation method

A technology of composite isolation layer and seed layer, which is applied in metal material coating technology, coating, ion implantation plating, etc., can solve the problems of long vacuuming time, huge equipment, and unfavorable high-temperature superconducting strips, etc., and achieves The effect of good surface finish, stable chemical properties and superior superconducting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] based on the following Figure 3 ~ Figure 7 Preferred embodiments of the present invention will be described in detail.

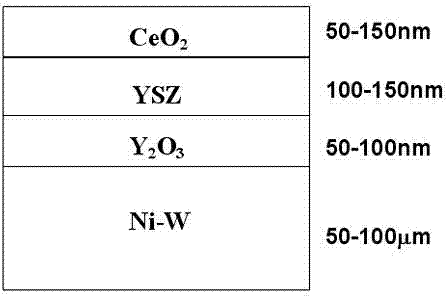

[0060] Such as image 3 Shown, is the simplified CeO provided by the present invention 2 / LaZrO 3 Schematic diagram of the structure of the composite isolation layer. The composite isolation layer adopts a double-layer structure, and the upper layer is LaZrO 3 layer, the lower layer (adjacent to the baseband) is CeO 2 seed layer. ZrO 3 The thickness of the layer is 100-200nm, CeO 2 The thickness of the seed layer is 50-100 nm.

[0061] The double-layer structure simplifies the structure of the composite isolation layer, reduces the number of isolation layers, greatly reduces the cost of coating, and improves the cost performance of the second-generation high-temperature superconducting strip.

[0062] Such as Figure 4 As shown, the present invention adopts multi-channel laser coating method to prepare simplified CeO 2 / LaZrO 3 Composite i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com