Metallurgical process for recovering metal copper, lead, zinc and tin from copper refining waste slag

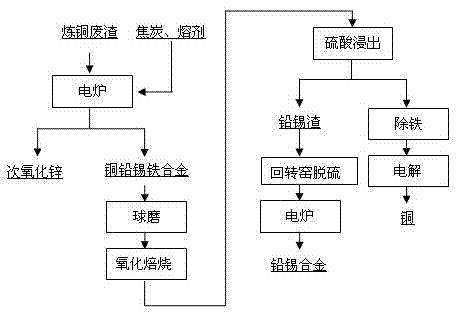

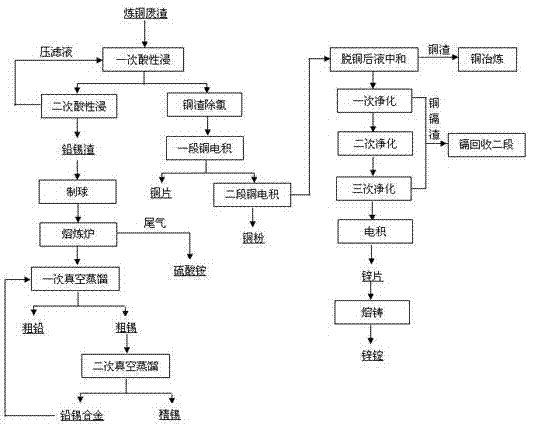

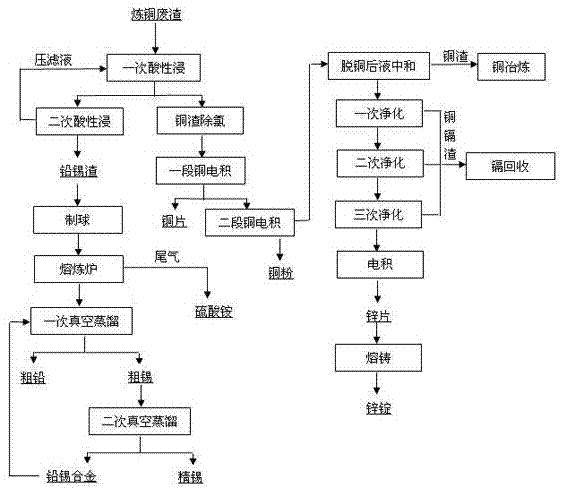

A technology for recovering copper and tin metals, which is applied to lead metal products, wet-fire cleaning combined new technology to extract copper, tin and zinc, can solve the problems of high waste gas treatment requirements, high production costs and long process flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Ingredients:

[0076] elementCu Pb Zn Sn Cd Fe Mn Co Ni content(%) 9.55 19.07 17.17 10.423.017.700.210.110.17 elementSiO 2 MgO CaOAl 2 O 3 Cl- SbFS As content(%)7.40.931.565.264.720.0920.930.830.085

[0077] Supplementary materials:

[0078] Manganese powder: MnO 2 55%;

[0079] Industrial sulfuric acid 98%;

[0080] Lime: 75%;

[0081] Zinc powder: 98%, effective zinc 88%.

[0082] The wet smelting in this experiment was carried out in the company's pilot plant, and one ton (dry basis) of copper smelting waste was put in for 30 days. The specific implementation is as follows:

[0083] 1. Primary acid leaching: add copper smelting waste residue to secondary acid leaching solution, 10m of zinc electrolytic waste solution 3 In the reaction tank, add sulfuric acid to control the pH of the leaching end point from 2.5 to 3, and the Fe in the leaching solution is required to be ≤ 1.5g / L. The leaching temperature is 85~95℃, the liquid-to-solid ratio is 2.5:1, and 7.5% (weight of ...

Embodiment 2

[0146] The raw material composition is shown in Table 3:

[0147] elementCu Pb Zn Sn Cd Fe Mn Co Ni content(%) 9.55 19.07 17.17 10.423.017.700.210.110.17 elementSiO 2 MgO CaOAl 2 O 3 Cl- SbFS As content(%)7.40.931.565.264.720.0920.930.830.085

[0148] Supplementary materials:

[0149] Manganese powder: MnO 2 55%;

[0150] Industrial sulfuric acid 98%;

[0151] Lime: 75%;

[0152] Zinc powder: 98%, effective zinc 88%;

[0153] It processes 70 tons of copper smelting waste every day for 3 months.

[0154] 1. Primary acid leaching: add copper smelting waste residue to secondary acid leaching solution, 54m of zinc electrolytic waste solution 3 In the reaction tank, add sulfuric acid to control the pH of the leaching end point from 2.5 to 3, and the Fe in the leaching solution is required to be ≤ 1.5g / L. The leaching temperature is 85~95℃, the liquid-to-solid ratio is 2.5:1, and 7.5% (weight of copper smelting residue) manganese powder is added for 4 hours (the pH value is controlled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com