Continuous type alloy steel heat treatment line

A technology of alloy steel and wire pairs, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., to achieve the effect of avoiding quenching deformation, eliminating fire hazards and oil smoke pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

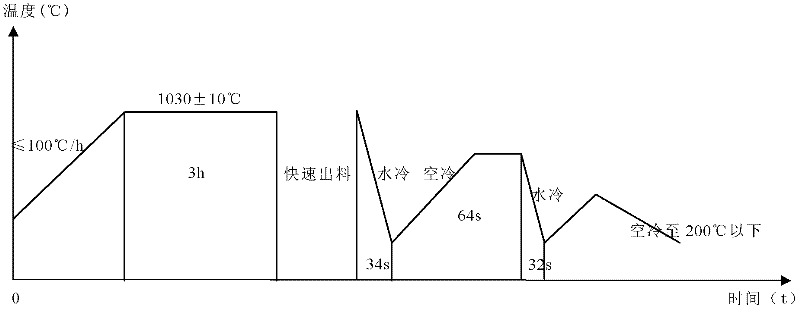

Embodiment 1

[0025] Such as figure 2 As shown, the 3Cr17 corrosion-resistant plastic mold flat steel has a thickness of 34mm, a width of 205mm, and a length of 6.0m. The steel is heated by gas in a continuous roller bottom heating furnace. The furnace temperature is ≤200°C and the heating rate is ≤100°C / h. Heating to 1030°C for austenitization and heat preservation for 3 hours; after the heat preservation is completed, the material is quickly discharged and enters the roller bottom quenching tank for water-air quenching (water cooling for 34 seconds→air cooling for 64 seconds→water cooling for 32 seconds). The steel is air-cooled to below 200°C and enters the electric heating continuous roller hearth furnace for tempering, the tempering temperature is 590°C, and the time is 5.5 hours; the tempered steel hardness reaches 30±1HRC, and the bending degree is not more than 2.5mm / m.

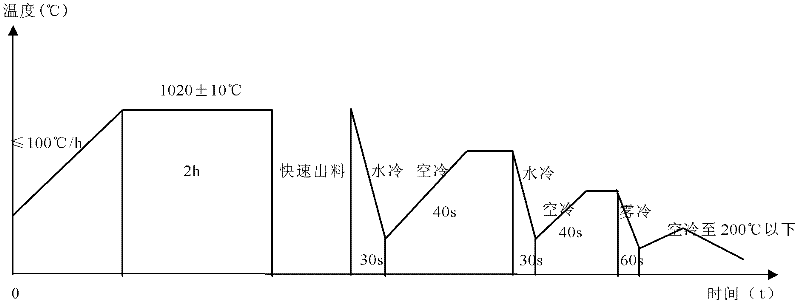

Embodiment 2

[0027] Such as image 3 As shown, the austenitic stainless steel 0Cr17Ni4Cu4Nb, the workpiece size is 75mm × 83mm, × 8.5m, is heated by gas in a continuous roller bottom heating furnace, and the temperature is raised to 1020°C for austenitization and heat preservation for 2 hours; after the heat preservation is completed, quickly The material is discharged into the roller bottom quenching tank for water immersion, fog cooling, air cooling and other combined cooling (water cooling for 30 seconds→air cooling for 40 seconds→water cooling for 30 seconds→air cooling for 40 seconds→fog cooling for 60 seconds). After the steel is air-cooled Enter the electric heating continuous roller hearth furnace for tempering below 200°C, and keep the tempering temperature at 635°C for 4 hours. Comprehensive properties: tensile strength 950MPa~1010MPa, yield strength 860MPa~910MPa, elongation after fracture 18%~22%, reduction of area 64%~70%, hardness (HBW) 297~310; bending degree not more than 2...

Embodiment 3

[0029] Such as Figure 4 As shown, Junjia-61 bearing steel ZGCr15, steel size ∮ 80mm ~ 120mm, heated in a continuous roller bottom heating furnace, heated to a temperature of 870 ° C, holding time 3 hours; after the heat preservation is completed, the material is quickly discharged and enters the roller Bottom-type quenching tank, after 30 seconds of water mist cooling (30 seconds of water cooling → 40 seconds of air cooling → 30 seconds of water cooling), the steel is air-cooled to 550 ° C, and then air-cooled to 300 ° C ~ 400 ° C; after electric heating continuous roller bottom Furnace spheroidizing annealing, steel mesh grade is 1.5~2.5 grade, spheroidization grade is 2.0~3.0 grade; bending degree is not more than 2.5mm / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com