Flexible package lithium ion battery and processing method thereof

A lithium ion battery and a processing method technology, which are applied in the field of flexible packaging lithium ion batteries and their processing, can solve the problems of reduced packaging effect, reduced packaging tension, and many processes and working hours, saving workstations and certain working hours, and reducing contact time, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

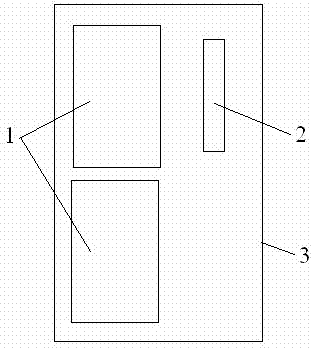

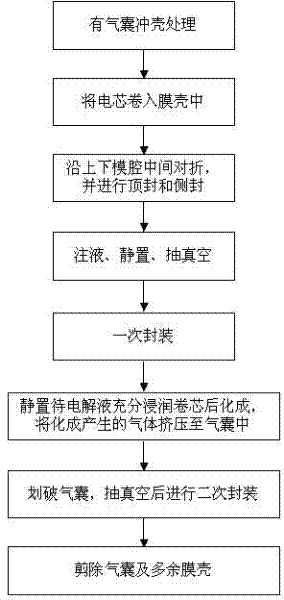

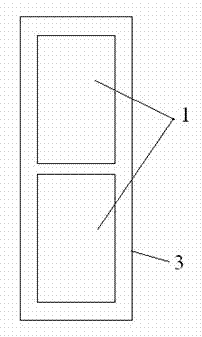

[0026] Such as image 3 Shown is the processing method flowchart of this embodiment, and this processing method comprises the following steps:

[0027] A. Airbag-free shelling, that is, when shelling, there is no need to keep the airbag structure in the aluminum-plastic film shell;

[0028] B. Roll the cell into the aluminum-plastic film case;

[0029] C. Fold in half along the upper and lower mold cavities, perform top sealing and side sealing, and seal a thin sheet check valve on the membrane shell at the same time;

[0030] D. Inject the liquid, let it stand until the electrolyte is completely absorbed, and then vacuumize;

[0031] E. Encapsulate the liquid injection side;

[0032] F. Formation.

[0033] Wherein, it is preferable to seal the sheet check valve into the top of the membrane shell, and at the lug glue, it is realized by melting and bonding the lug glue and the inner PP layer of the aluminum-plastic film to ensure a better packaging effect. The sheet check ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com