Intelligent anti-impact bracket device

A support device and anti-shock technology, which is applied to pillars/supports, roof beams supporting mine roofs, mining equipment, etc. Resistance to load capacity, easy handling and installation, and the effect of protecting hydraulic supports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

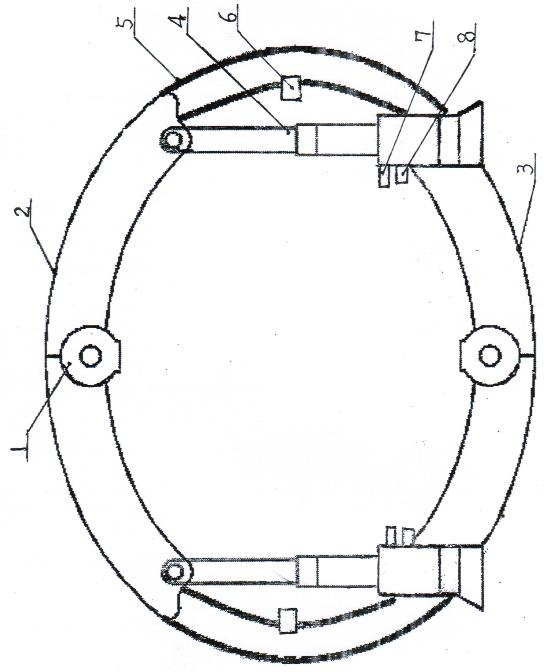

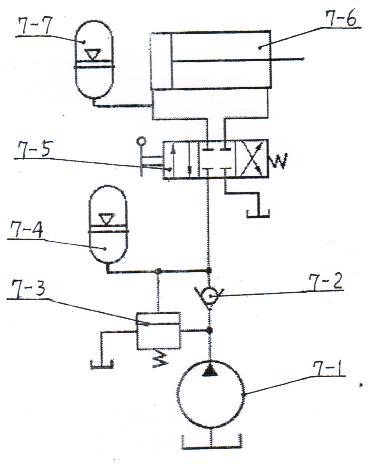

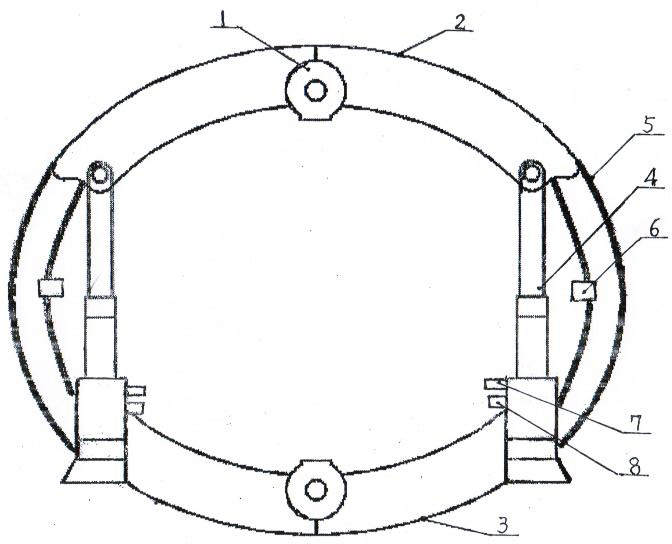

[0010] Examples, see attached figure 1 , 2 , The middle of the top beam 2 and the bottom beam 3 of the intelligent anti-impact bracket device is divided into two halves, and the two halves of the top beam 2 and the bottom beam 3 are hingedly connected at the middle division of the top beam 2 and the bottom beam 3 together. The top and low ends of the hydraulic support 4 are hinged to connect the two ends of the top beam 2 and the bottom beam 3 respectively. The top beam 2 and the bottom beam 3 are hingedly connected with the baffle 5 at both ends. A stress sensor 6 is installed in the middle of the baffle 5. The bottom side of the hydraulic support 4 is installed with a displacement sensor 8 and an anti-scour component 7. Anti-surge component 7 is hydraulic pump 7-1 connected to check valve 7-2, check valve 7-2 connected to overflow valve 7-3 and hydraulic accumulator 7-4, hydraulic accumulator 7-4 connected to reversing The valve 7-5 and the reversing valve 7-5 are connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com