Heat treatment process for improving GH4145 alloy pipe

A technology of GH4145 and pipe materials, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of fast cooling speed, cracking, low temperature, etc., and achieve the effects of improved processing performance, smooth inner and outer surfaces, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Heat treatment: In the first stage, heat up to 600°C with the furnace for 15 minutes; in the second stage, heat to 980°C and hold for 20 minutes;

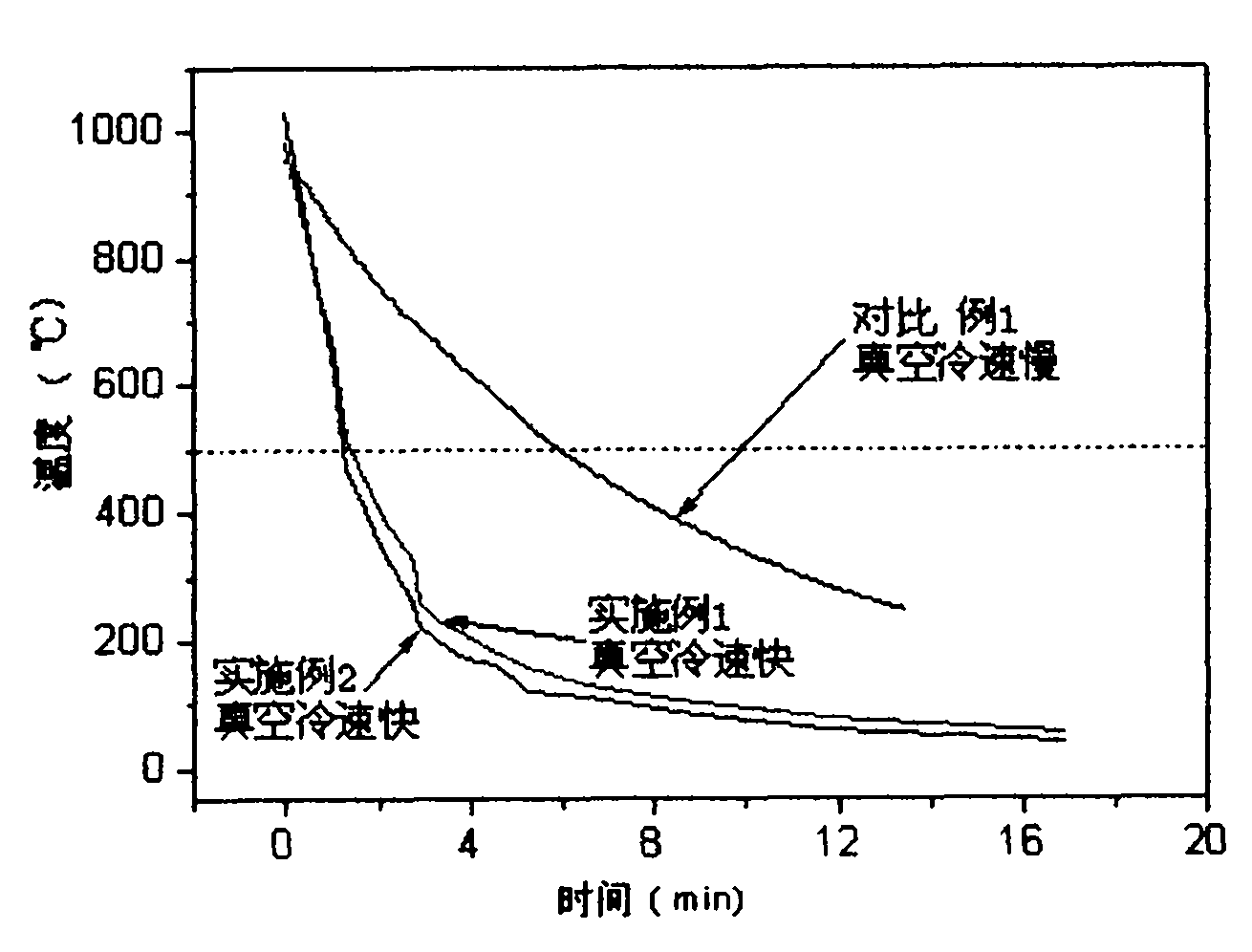

[0020] Rapid cooling: the cooling gas is nitrogen, the cooling pressure is 4bar, and the cooling rate is greater than 350°C / min before cooling to 500°C (cooling rate see figure 1 ), and then cooled to room temperature with the furnace.

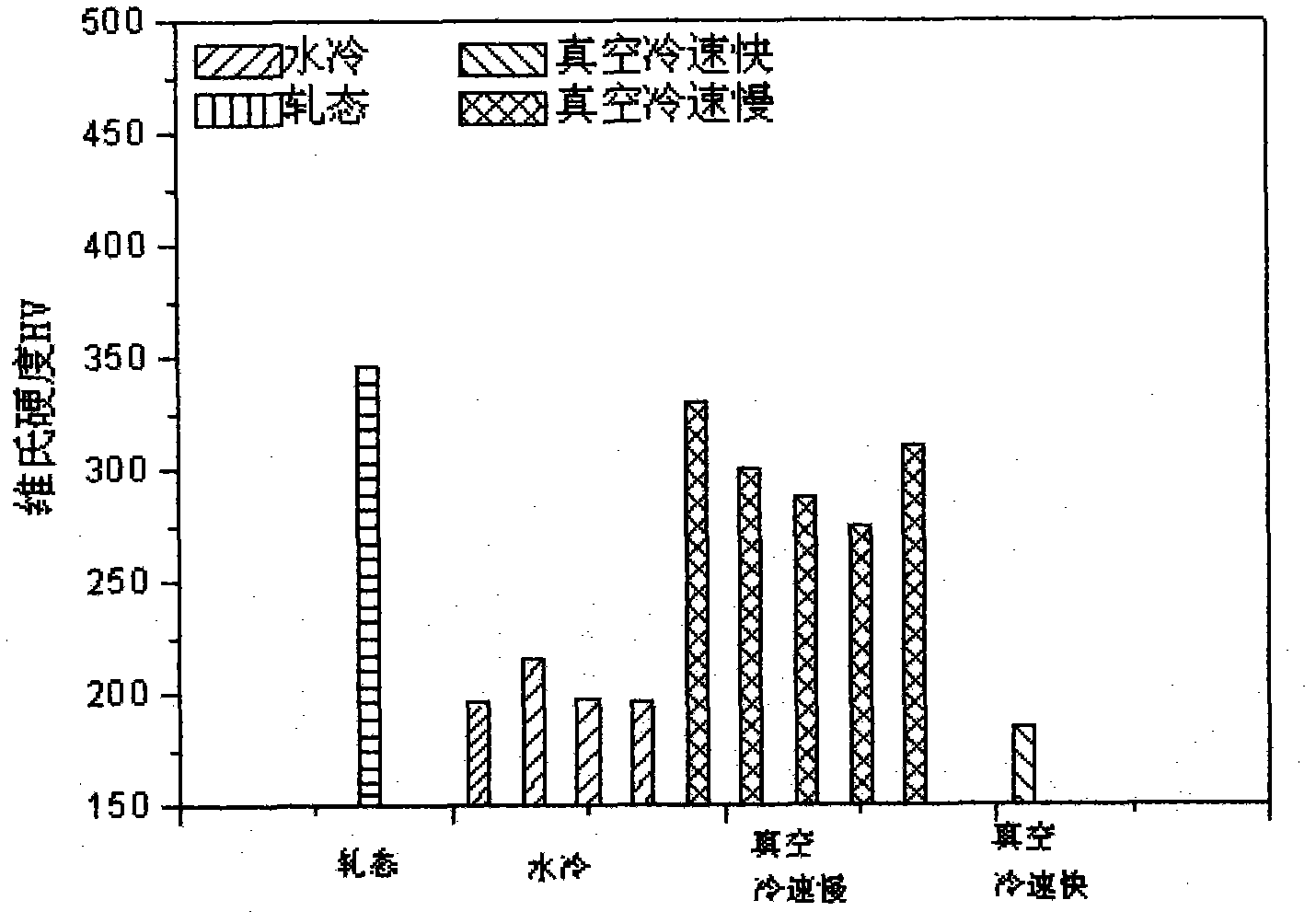

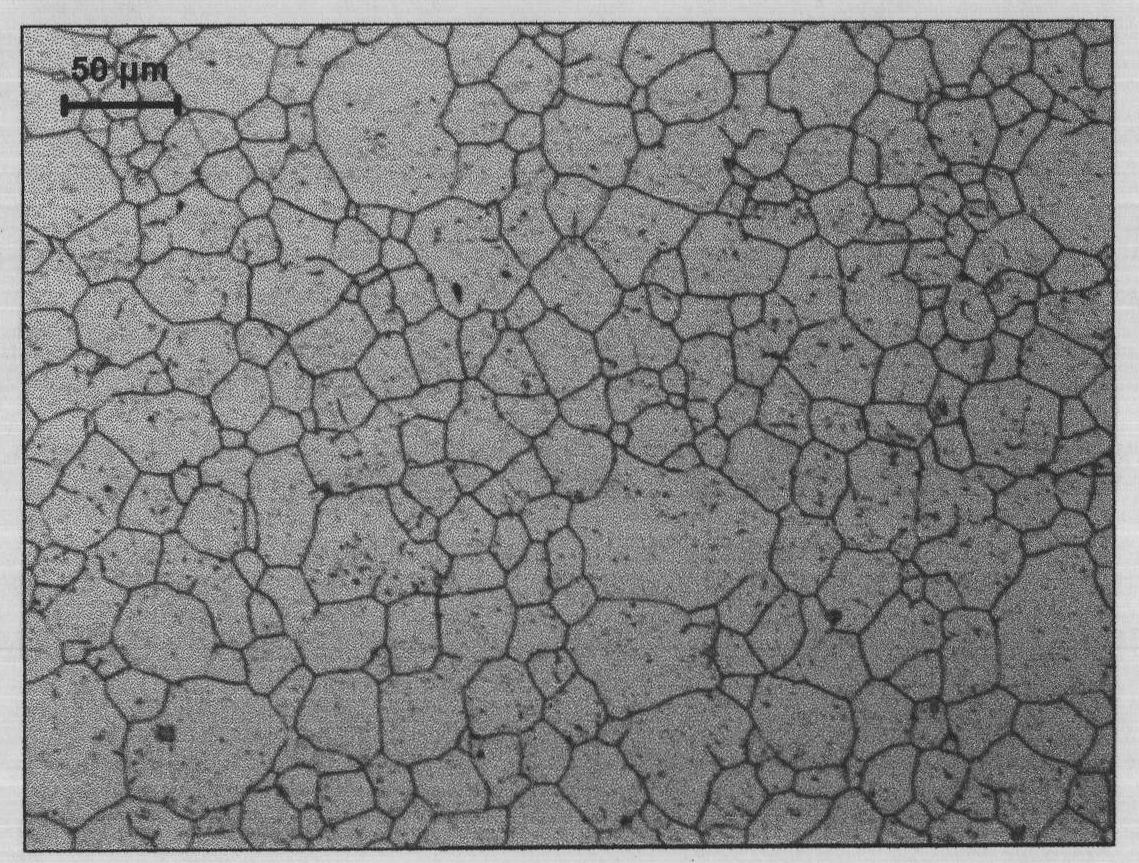

[0021] The organizational chart of the resulting finished product is shown in image 3 , whose hardness see figure 2 , see Table 1 for performance data.

Embodiment 2

[0023] Heat treatment: In the first stage, heat up to 600°C with the furnace for 20 minutes; in the second stage, heat to 1030°C and hold for 15 minutes;

[0024] Rapid cooling: the cooling gas is argon, the cooling pressure is 6bar, and the cooling rate is greater than 350°C / min before cooling to 500°C (cooling rate see figure 1 ), and then cooled to room temperature with the furnace.

[0025] The organizational chart of the resulting finished product is shown in Figure 4 , and its performance data are shown in Table 1.

Embodiment 3

[0027] Heat treatment: In the first stage, heat up to 600°C with the furnace for 15 minutes; in the second stage, heat to 1000°C and hold for 18 minutes;

[0028] Rapid cooling: the cooling gas is argon, the cooling pressure is 5bar, and the cooling rate is greater than 350°C / min before cooling to 500°C, and then cooled to room temperature with the furnace.

[0029] The organizational chart of the resulting finished product is shown in Figure 5 , and its performance data are shown in Table 1.

[0030] Table 1 Comparison of pipe properties at different cooling rates

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com