Mutant blocked in glycerol oxidaion pathway for producing 1,3-propanediol

A technology of propylene glycol and glycerol, applied in biochemical equipment and methods, transferase, enzyme and other directions, can solve problems such as high manufacturing cost and waste oil generation

- Summary

- Abstract

- Description

- Claims

- Application Information

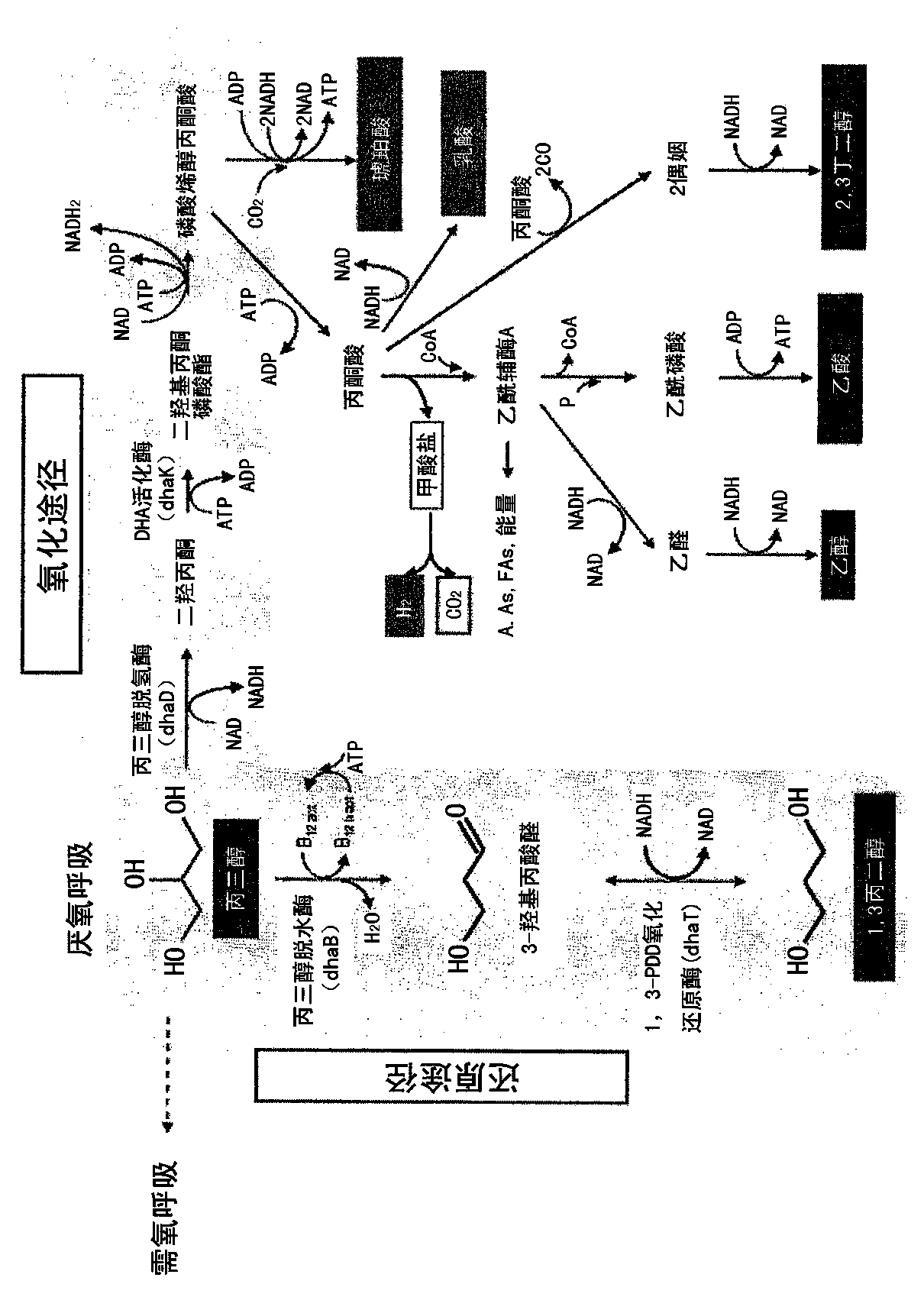

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

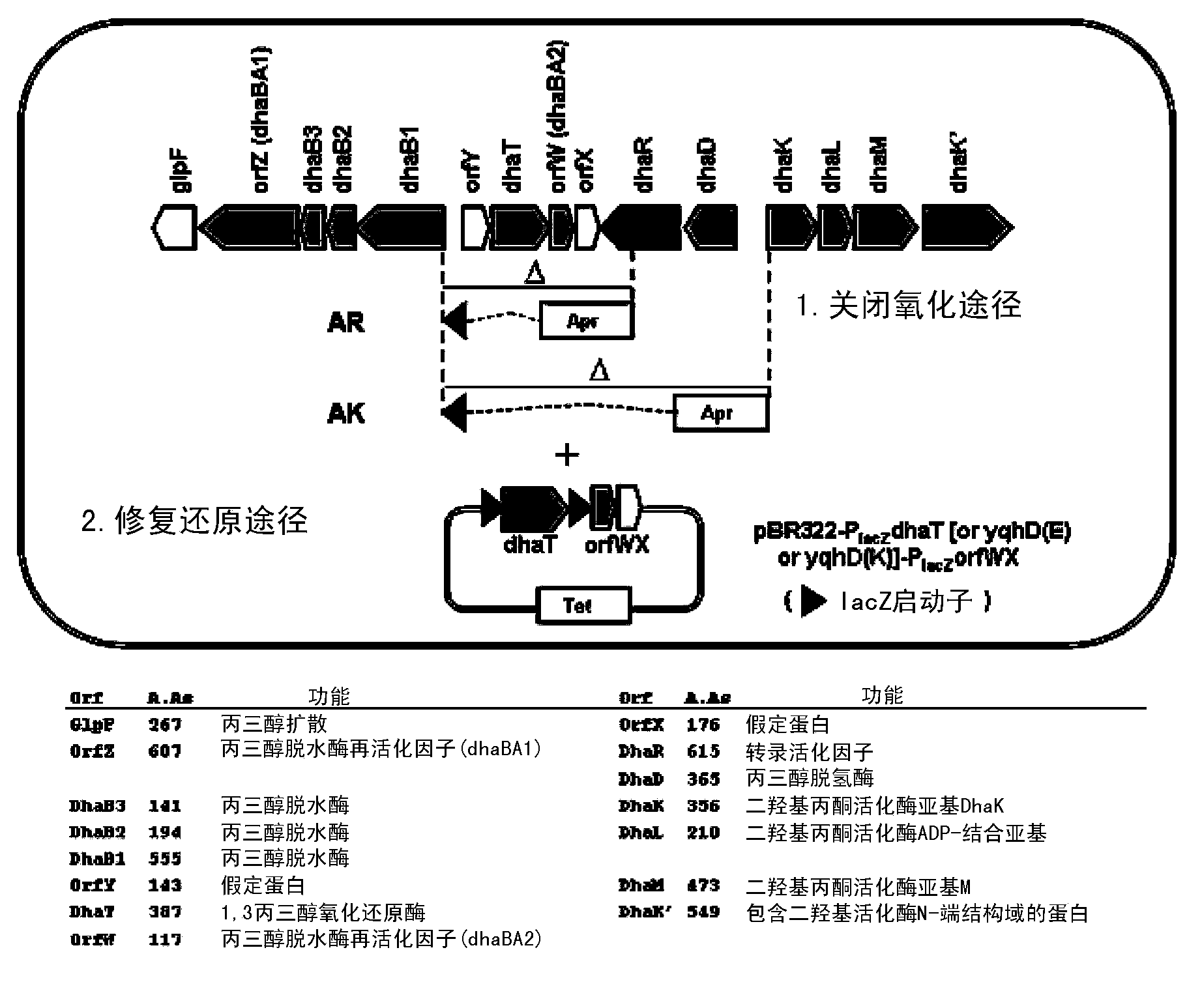

[0054] Example 1: Preparation of recombinant bacterial strains blocked by the oxidation-reduction metabolic pathway of glycerol

[0055]For the redesign of the glycerol metabolic pathway, the recombinant bacterial strain in which the glycerol metabolic pathway in Klebsiella MGH78578 (ATCC 700721) was completely blocked was prepared as the basic strain. The antibiotic resistance profile of the Klebsiella MGH 78578 strain was analyzed in order to fix a selection marker that could be used in the genetic recombination process. Therefore, it was found that apramycin (50 / ml) can be used as an antibiotic marker for the screening of recombinant strains. In addition, the plasmid initially present in the strain was removed by processing and tetracycline was added as an available selectable marker. Using plasmid DNA-treated Klebsiella MGH 78578 strain (named "Cu") as a parent strain, the DhaD gene of the DhaB enzyme reactivator, DhaT gene, DhaR regulator, and dha regulator ( figure 2 ...

Embodiment 2

[0077] Example 2: Analysis of the properties of Klebsiella strains AK and AR

[0078] The proliferation and glycerol metabolism properties of recombinant Klebsiella strains AK and AR, in which the anaerobic metabolic pathway for glycerol was removed, were analyzed. Each strain of AK and AR was cultured into a medium supplemented with glycerol and incubated at 37° C. at 180 rpm for 12 hours. Then, the degree of proliferation of the cells was studied, and the content of glycerol present in the culture supernatant and the metabolites produced including 1,3-propanediol were analyzed by chromatography (device used: Agilent 1200 (refractive index detector , RID); used column: Aminex HPX-87H (Bio-Rad) 300mm×78mm; used solvent: 65:35 deionized water-acetonitrile (0.005M H 2 SO 4 ); and flow rate: 0.5ml / min. The AK and AR strains showed cell proliferation rates that were about two times slower than the parent strain Cu used as a control, and their glycerol consumption rates and 1,3-...

Embodiment 3

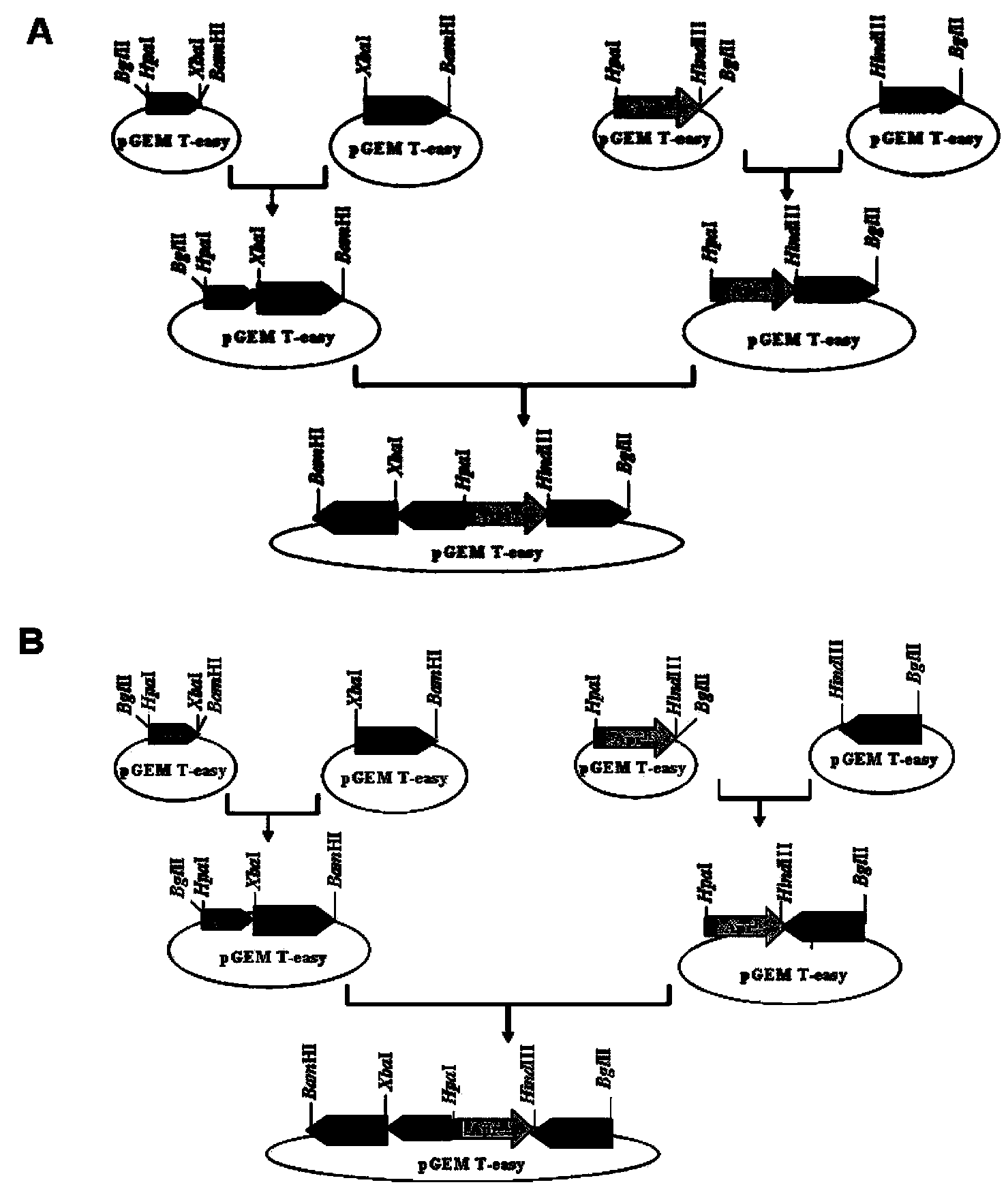

[0079] Embodiment 3: the bacterial strain that the reductive pathway of preparation glycerol is repaired

[0080] (1) Preparation of plasmid DNA for repairing the reduction pathway of glycerol

[0081] DhaB reactivase gene (orfW)-orfX DNA fragments and dhaT, yqhD (from E. coli) or yqhD homologous genes (from Klebsiella) with 1,3-propanediol oxidoreductase activity were amplified using the following primer sequences. The amplified gene was cloned into pGEM TEasy vector, and its basic sequence was analyzed. Then, if Figure 5 Plasmid DNAs were prepared as indicated in .

[0082] SEQ ID NO: 9: 5'-AGATCTATGAGCTATCGTATGTTTGA-3'(dhaT-BglII F)

[0083] Sequence number 10: 5'-CTCGAGAAGCTTCAGAATGCCTGGCGGAAAAT-3'

[0084] (dhaT-HindIII / XhoI R)

[0085] SEQ ID NO: 11: 5'-AGATCTATGAACAACTTTAATCTGCAC-3'(yqhD-BglII F)

[0086] SEQ ID NO: 12: 5'-AGATCTATGAATAATTTCGACCTGCA-3'(yqhD-HindIII /

[0087] XhoI R)

[0088] SEQ ID NO: 13: 5'-AGATCTATGAATAATTTCGACCTGCA-3'(yqhD Kle BglII F)

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com