Dry distillation and liquefying method for coal

A dry distillation and coal technology, applied in the field of coal chemical industry, can solve the problems of difficult recycling and reuse of molybdenum-based catalysts, high industrialization cost, and difficult separation of products, so as to reduce the cost of coal-to-oil conversion, low cost, and low operating pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

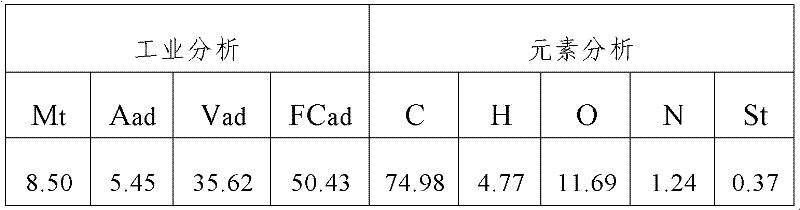

Embodiment 1

[0028] Step 1. Mix the Shenmu coal, the catalyst and the co-catalyst evenly, and then crush the mixture until the particle size is no more than 200 mesh, so as to obtain the coal powder loaded with the catalyst; the catalyst is a nanometer iron-based catalyst, and the amount of the catalyst is 1 / 2 of the weight of the raw coal 3%; the co-catalyst is elemental sulfur, and the consumption of the co-catalyst is 5% of the raw coal weight; the nano-iron series catalyst is prepared by the following method: in the ferrous sulfate solution whose mass concentration is 10%, add A dispersant and a precipitating agent are stirred and reacted at room temperature for 3 hours to obtain a nano-iron catalyst with a colloidal particle size not greater than 20nm; the dispersant is sodium dodecylbenzenesulfonate, and the amount of the dispersant is ferrous sulfate solution 0.1% of the mass; the precipitating agent is urea, and the addition of the precipitating agent is 2% of the ferrous sulfate so...

Embodiment 2

[0035] Step 1. Mix the Shenmu coal, the catalyst and the co-catalyst evenly, and then crush the mixture until the particle size is no more than 200 mesh, so as to obtain the coal powder loaded with the catalyst; the catalyst is a nanometer iron-based catalyst, and the amount of the catalyst is 1 / 2 of the weight of the raw coal 1.5%; the cocatalyst is elemental sulfur, and the consumption of the cocatalyst is 3% of the raw coal weight; the nano-iron series catalyst is prepared by the following method: adding A dispersant and a precipitating agent are stirred and reacted at room temperature for 8 hours to obtain a nano-iron catalyst with a colloidal particle size not greater than 20nm; the dispersant is sodium dodecylbenzenesulfonate, and the amount of the dispersant is ferrous sulfate solution 0.2% of the mass; the precipitating agent is urea, and the addition of the precipitating agent is 4% of the ferrous sulfate solution quality;

[0036] Step 2: Use semi-coke powder at a te...

Embodiment 3

[0042]Step 1. Mix the Shenmu coal, the catalyst and the co-catalyst evenly, and then crush the mixture until the particle size is no more than 200 mesh, so as to obtain the coal powder loaded with the catalyst; the catalyst is a nanometer iron-based catalyst, and the amount of the catalyst is 1 / 2 of the weight of the raw coal 0.5%; the cocatalyst is elemental sulfur, and the consumption of the cocatalyst is 1% of the raw coal weight; the nano-iron series catalyst is prepared by the following method: adding A dispersant and a precipitating agent are stirred and reacted at room temperature for 5 hours to obtain a nano-iron catalyst with a colloidal particle size not greater than 20nm; the dispersant is sodium dodecylbenzenesulfonate, and the amount of the dispersant is ferrous sulfate solution 0.15% of the mass; the precipitating agent is urea, and the addition of the precipitating agent is 3% of the ferrous sulfate solution quality;

[0043] Step 2. Use semi-coke powder at a te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com