Preparation method of foamed aluminum and alloy sandwich plate

A foamed aluminum and sandwich panel technology, applied in the direction of chemical instruments and methods, metal layered products, layered products, etc., can solve the problems of heat damage to foam core materials, achieve low processing costs, anti-aging and external impact And the effect of increased anti-fatigue ability and high structural precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

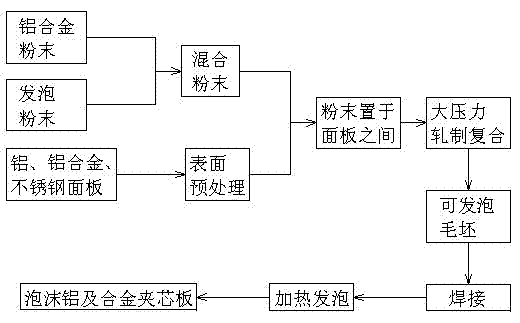

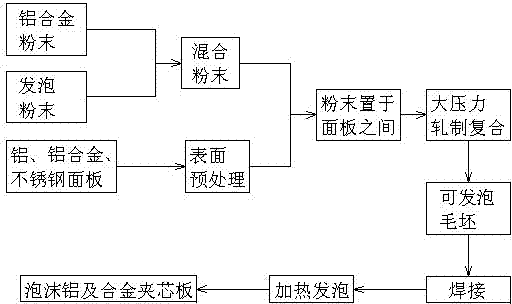

[0020] Embodiment one: see figure 1 Shown, a kind of preparation method of aluminum foam and alloy sandwich panel comprises the following steps:

[0021] (1) Coating treatment of foamed aluminum and alloys and powder: select the prepared aluminum and alloy panels, aluminum and alloy panels and powder to be foamed, and press them on the rolling sub-unit to prepare rough foamed aluminum and alloy sandwich panels;

[0022] (2) Welding: Grind and clean the welded surface of the prepared blank aluminum foam and alloy sandwich panel, clamp and position the blank aluminum foam and composite sandwich panel through the positioning device, and then weld it, and then Obtain rough aluminum foam and alloy sandwich panels of required specifications and sizes;

[0023] (3) Foaming: put the foamed aluminum and alloy sandwich panels welded with blanks into a heating furnace for heating, the heating temperature is 300-600°C, and the heating time is 10-40 minutes;

[0024] (4) Cooling: Place t...

Embodiment 2

[0026] Embodiment two: technology is similar to embodiment one.

[0027] Select aluminum alloy as the panel, and after coating the powder, carry out large-scale deformation pressing on a large rolling mill or a large-tonnage press to prepare a sandwich panel blank; polish and clean the parts to be welded, and then clamp and position them in the center, using laser The welding equipment is used for welding, and then put into a heating furnace for heating. The temperature is slowly raised from 300°C to 600°C, kept for 20 minutes, and then the power is turned off quickly, thereby preparing the aluminum foam sandwich panel.

Embodiment 3

[0028] Embodiment three: technology is similar to embodiment one.

[0029] Take stainless steel as the panel, coat the powder and carry out large deformation pressing on a large rolling mill or a large tonnage press to prepare a sandwich panel blank; polish and clean the parts to be welded, and then clamp and position them in the center, using argon arc The welding equipment is used for welding, and then put into a heating furnace for heating. The temperature is slowly raised from 300°C to 600°C, kept for 40 minutes, and then the power is turned off quickly, thereby preparing the aluminum foam sandwich panel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com