Spraying and washing process of ammonium sulfate crystallizer by non-saturator method

A crystallizer and saturator technology, applied in the field of coking, can solve the problems of increasing raw material consumption, unfavorable energy saving and consumption reduction, increasing energy consumption, etc., and achieves the effects of reducing energy consumption and operating cost, reducing the number of start-up and shutdown, and prolonging the operation period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

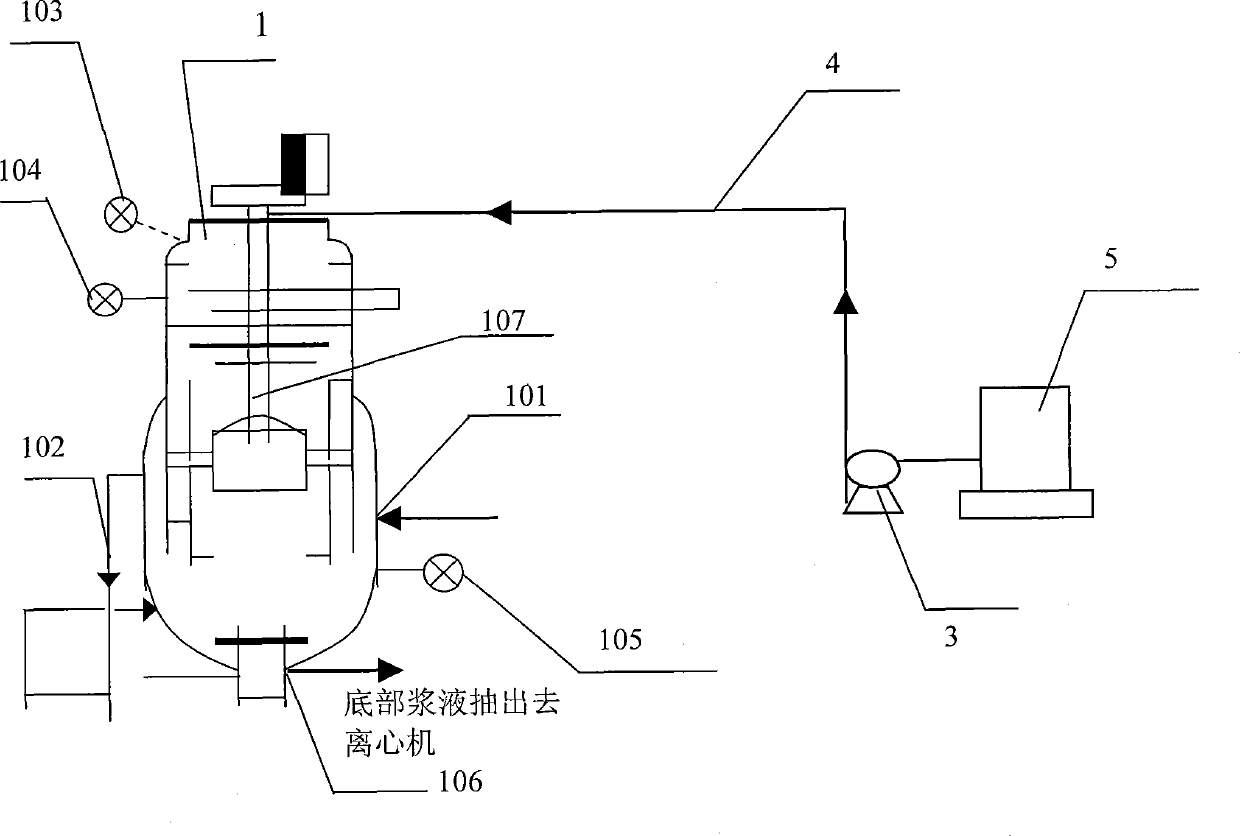

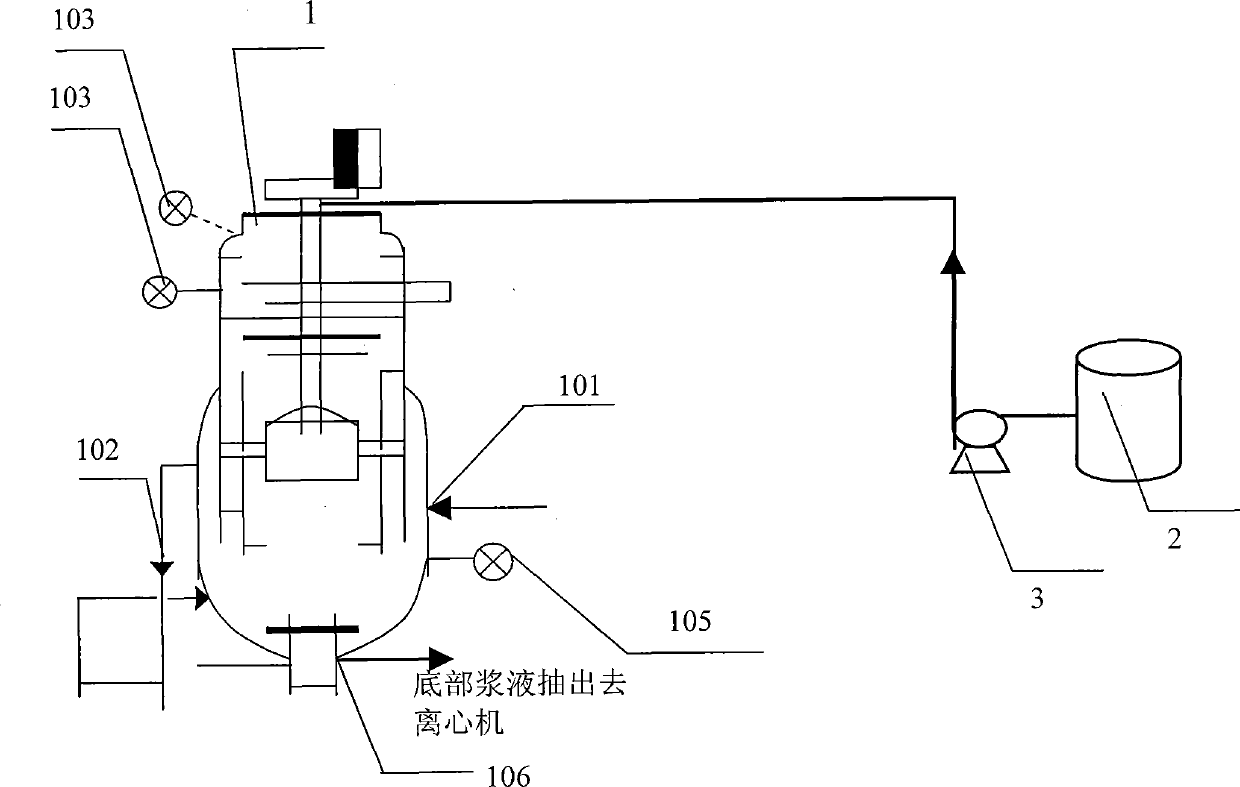

[0019] Such as figure 2 As shown, ammonium sulfate crystallizer 1 is provided with ammonium sulfate mother liquor inlet 101, ammonium sulfate mother liquor circulation heating system 102, crystallizer pressure control device 103, crystallizer top temperature control device 104, crystallizer bottom temperature control device 105 and slurry extraction Mouth 106. Simultaneously, the ammonium sulfate crystallizer is also provided with a washing pipeline 4.

[0020] There is also a volume of 10m 3 The distilled ammonia concentrated ammonia water storage tank 2 is used to collect the distilled ammonia concentrated ammonia water produced by the distillation of ammonia water, and is connected to the washing pipeline through the delivery pump 3, and the original separated water or condensed water pipe is cut off.

[0021] The concentration of the distilled concentrated ammonia water in the distilled ammonia concentrated ammonia water storage tank 2 is 5wt%, and the temperature is 45...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com