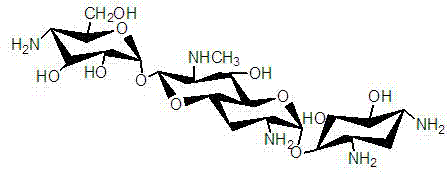

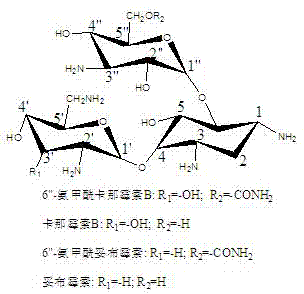

Engineering bacterium for generating carbamoyl tobramycin and application thereof

A carbamoyl tobramycin and engineering bacteria technology, applied in bacteria, microorganisms, biochemical equipment and methods, etc., can solve problems such as pollution, environmental pollution, difficulties, etc., to reduce environmental pollution, reduce production costs, and simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Source of reagents: pMD19-T and restriction endonucleases were purchased from TaKaRa Company, plasmid pAGe (containing resistance gene ermE) was donated by Dr. Shao Lei of Shanghai Institute of Pharmaceutical Industry, and plasmid pBR322 (containing tetracycline resistance gene) was provided by our laboratory save.

[0030] The present invention mainly comprises following major steps:

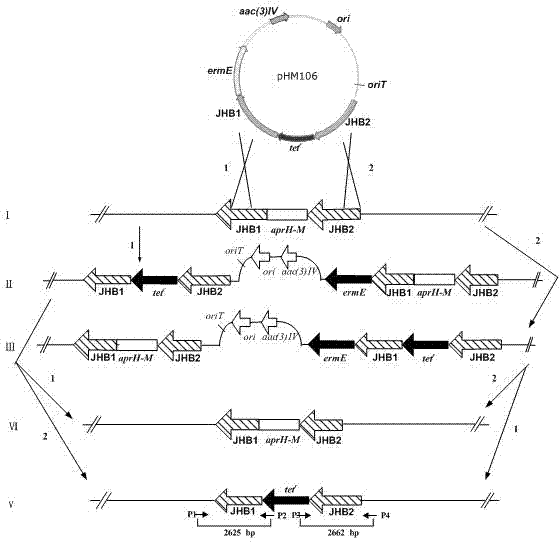

[0031] 1. Construct aprH-M gene replacement plasmid

[0032] Using the apramycin (also known as abramycin) biosynthetic gene cluster sequence (GenBank Accession Number AJ629123) published by Piepersberg et al. Breeding of carbamoyl tobramycin high-yielding strains and their fermentation characteristics [J]. Chinese Journal of Antibiotics, 2008, 33 (7): 442-445) Existence of abramycin biosynthetic gene clusters on chromosomal DNA. and then respectively in aprH-M Two pairs of primers SD1 / SD2 and SD3 / SD4 were designed for the upstream and downstream of the gene to extract the tot...

Embodiment 2

[0044] Embodiment 2: Preparation of tobramycin, a metabolite of Streptomyces melanogaster HM106

[0045] The engineering bacterium HM106 provided by the invention can be directly used to produce tobramycin, and the engineering bacterium is fermented to extract metabolites to prepare tobramycin as an antibacterial drug.

[0046] 1. Fermentation and cultivation of Streptomyces melanogaster HM106 engineering bacteria

[0047] Seed medium: glucose 5g, cornstarch 10g, soybean meal 15g, potassium dihydrogen phosphate 0.5g, potassium chloride 1g, calcium chloride 0.25g, magnesium sulfate 5g, add tap water to 1L.

[0048] Fermentation medium: glucose 15g, corn flour 20g, soybean cake powder 35g, magnesium sulfate 11g, calcium carbonate 7g, fish meal 6g, zinc sulfate 0.1g, ammonium sulfate 7g, cornstarch 20g, amylase 0.5g, add tap water to 1L, The pH was adjusted to 7.0-7.2 with sodium hydroxide solution.

[0049] The genetically engineered bacterium Streptomyces melanogaster HM106 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com