Method for controlling growth of pipeline biological film by utilizing bromine chlorine hydantoin liposome

A technology of bromochlorohydantoin and liposomes, which is applied in the field of water treatment, can solve the problems of patent and research without pipeline microbial stripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

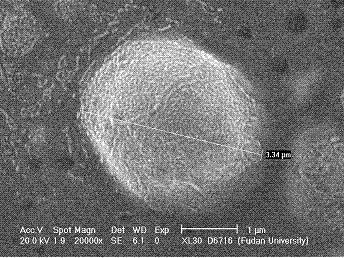

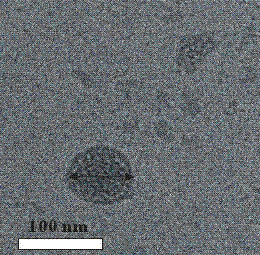

[0034] Accurately weigh 1.2g soybean lecithin and 0.6g cholesterol, dissolve in 10mL chloroform and 15 mL diethyl ether mixed solvent, add 6mL 2 g / L BCDMH phosphate buffer solution (PBS, pH=6.8, filter to remove suspended matter), Sonicate in a water bath for 0.5 min to form an emulsion. The emulsion was poured into an eggplant-shaped bottle and placed on a rotary evaporator. After the pressure was reduced to 0.02 MPa, the emulsion was evaporated at 30 °C for 8 h to remove the organic solvent. The rotation speed of the eggplant-shaped bottle was 100 r / min. Remove the eggplant-shaped bottle and blow off with nitrogen to remove the hard-volatile ether present in the emulsion. After continuing to evaporate for 8 hours, a uniform lipid film was formed on the wall of the bottle. Add 40 mL, 2 g / L PBS (pH=6.8) and continue to rotate for 6-9 hours. white) liposome suspension. The microporous membrane (particle size: 0.8 μm) soaked in PBS (pH=6.8) was used to filter and remove large ...

Embodiment 2

[0037] Weigh 1g soybean lecithin and 0.4g cholesterol, dissolve in 5mL chloroform and 10mL diethyl ether mixed solvent, add 8mL 2 g / L BCDMH phosphate buffer solution (PBS, pH=6.8, filter to remove suspended matter), water bath ultrasonic Treat for 1 min to form an emulsion. The emulsion was poured into an eggplant-shaped bottle and placed on a rotary evaporator. After the pressure was reduced to 0.04 MPa, the emulsion was evaporated at 37.5 °C for 12 h to remove the organic solvent. The rotation speed of the eggplant-shaped bottle was 135 r / min. Remove the eggplant-shaped bottle and blow off with nitrogen to remove the hard-volatile ether present in the emulsion. After continuing to evaporate for 12 hours, a uniform lipid film was formed on the wall of the bottle. Add 60mL, 2 g / L PBS (pH=6.8) and continue to rotate for 7.5 hours. liposome suspension. The microporous membrane (particle size: 0.8 μm) soaked in PBS (pH=6.8) was used to filter and remove large particles of impur...

Embodiment 3

[0040]Weigh 1.4 g soybean lecithin and 0.8 g cholesterol, dissolve in 15 mL chloroform and 20 mL diethyl ether mixed solvent, add 10 mL 2 g / L BCDMH phosphate buffer solution (PBS, pH=6.8, filter to remove suspended matter) , ultrasonically treated in a water bath for 2 min to form a stable emulsion. The emulsion was put into an eggplant-shaped bottle and placed on a rotary evaporator. After the pressure was reduced to 0.06 MPa, the emulsion was evaporated at 45 °C for 16 h to remove the organic solvent. The rotation speed of the eggplant-shaped bottle was 165 r / min. Remove the eggplant-shaped bottle and blow off with nitrogen to remove the hard-volatile ether present in the emulsion. After continuing to evaporate for 16 hours, a uniform lipid film was formed on the wall of the bottle. Add 80 mL, 2 g / L PBS (pH=6.8) and continue to rotate for 9 hours. liposome suspension. The microporous membrane (particle size: 0.8 μm) soaked in PBS (pH=6.8) was used to filter and remove larg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com