Method for processing waste liquid containing calcium citrate

A technology of calcium citrate and treatment method, applied in flocculation/precipitation water/sewage treatment, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problem of affecting the neutralization yield, difficulty in sedimentation and recovery, and increasing the burden of environmental protection treatment And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

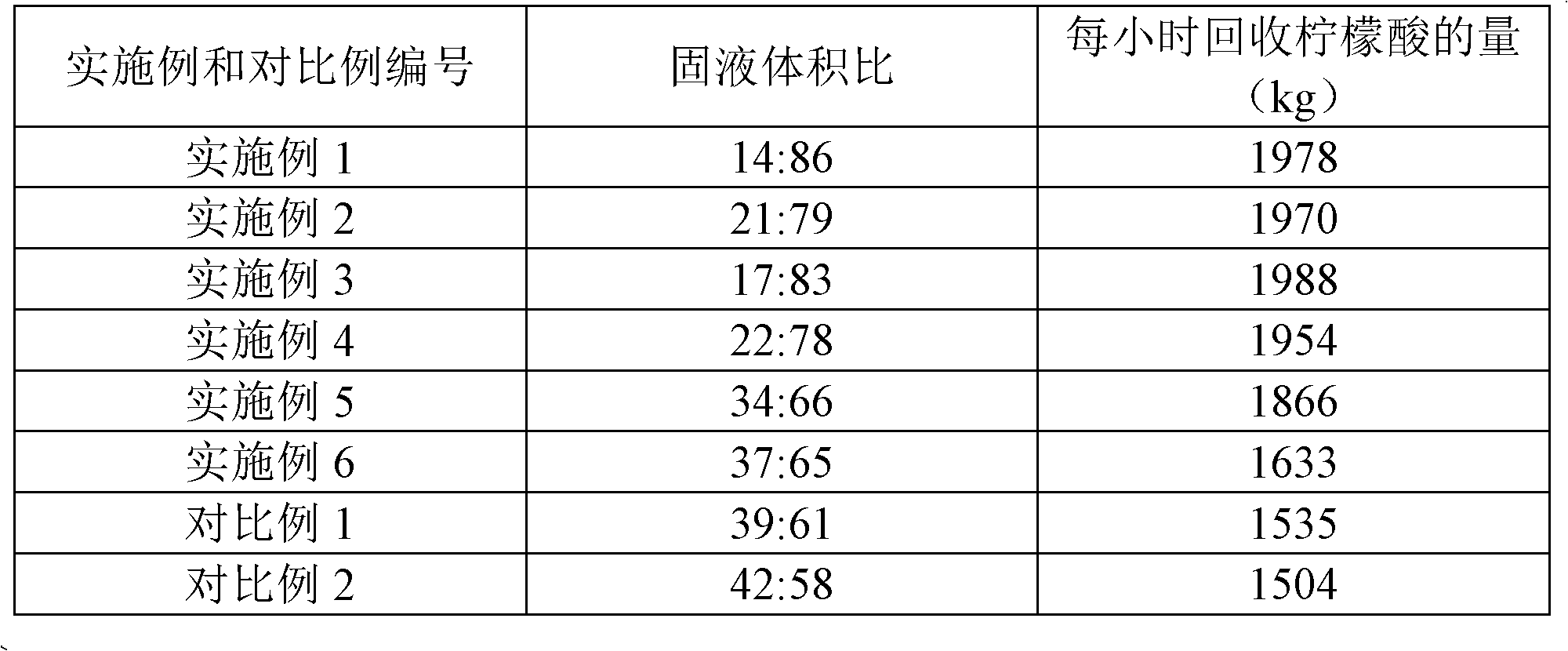

Examples

Embodiment 1

[0026]This embodiment is used to illustrate the treatment method of the wastewater containing calcium citrate provided by the invention.

[0027] (1) 500mL of waste liquid containing calcium citrate is placed in a settling tank, and the waste liquid is heated to 50°C;

[0028] (2) Sodium alginate with a number average molecular weight of 32000 is dissolved in water to obtain a sodium alginate aqueous solution with a concentration of 15 ppm; and under stirring, the waste liquid obtained in step (1) is mixed with the sodium alginate aqueous solution ; Based on the waste liquid containing calcium citrate per cubic meter, the addition of the sodium alginate aqueous solution makes the consumption of sodium alginate be 0.15 kilograms, and flocs appear after stirring and mixing for 5 minutes;

[0029] (3) Add 4 kilograms of perlite (purchased from Linglong Thermal Insulation Material Factory, Pingqiao District, Xinyang City, Henan Province) to the mixed solution obtained in step (1),...

Embodiment 2

[0031] This embodiment is used to illustrate the treatment method of the wastewater containing calcium citrate provided by the invention.

[0032] (1) 500mL of waste liquid containing calcium citrate is placed in a settling tank, and the waste liquid is heated to 70°C;

[0033] (2) Potassium alginate with a number average molecular weight of 32000 is dissolved in water to obtain a potassium alginate aqueous solution with a concentration of 10 ppm; and under stirring, the waste liquid obtained in step (1) is mixed with the potassium alginate aqueous solution ; Based on the waste liquid containing calcium citrate per cubic meter, the addition of the potassium alginate aqueous solution makes the consumption of potassium alginate be 0.1 kilogram, and flocs appear after stirring and mixing for 0.5 minutes;

[0034] (3) Add 3 kilograms of activated carbon (purchased from Beijing Guanghua Jingke Co., Ltd.) into the mixed solution obtained in step (1), after stirring for 10 seconds, s...

Embodiment 3

[0036] This embodiment is used to illustrate the treatment method of the wastewater containing calcium citrate provided by the invention.

[0037] (1) 500mL of waste liquid containing calcium citrate is placed in a settling tank, and the waste liquid is heated to 60°C;

[0038] (2) dissolving sodium alginate with a number average molecular weight of 200,000 in water to obtain a sodium alginate aqueous solution with a concentration of 5 ppm; and mixing the waste liquid obtained in step (1) with the sodium alginate aqueous solution under stirring ; Based on the waste liquid containing calcium citrate per cubic meter, the addition of the sodium alginate aqueous solution makes the consumption of sodium alginate be 0.05 kg, and flocs appear after stirring and mixing for 2 minutes;

[0039] (3) 2 kilograms of diatomite (purchased from Linjiang Sailit Company) are added to the mixed solution obtained in step (1), after stirring for 20 seconds, stop stirring, and after standing for 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com