Method for preparing tin-copper alloy materials and carbon covered tin-copper alloy materials

A technology of tin-copper alloy and carbon coating, which is applied in metal material coating process, liquid chemical plating, coating, etc., can solve the problems of harsh preparation conditions, difficulty in large-scale production, complex process, etc., and achieve stable performance, The effect of high capacity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

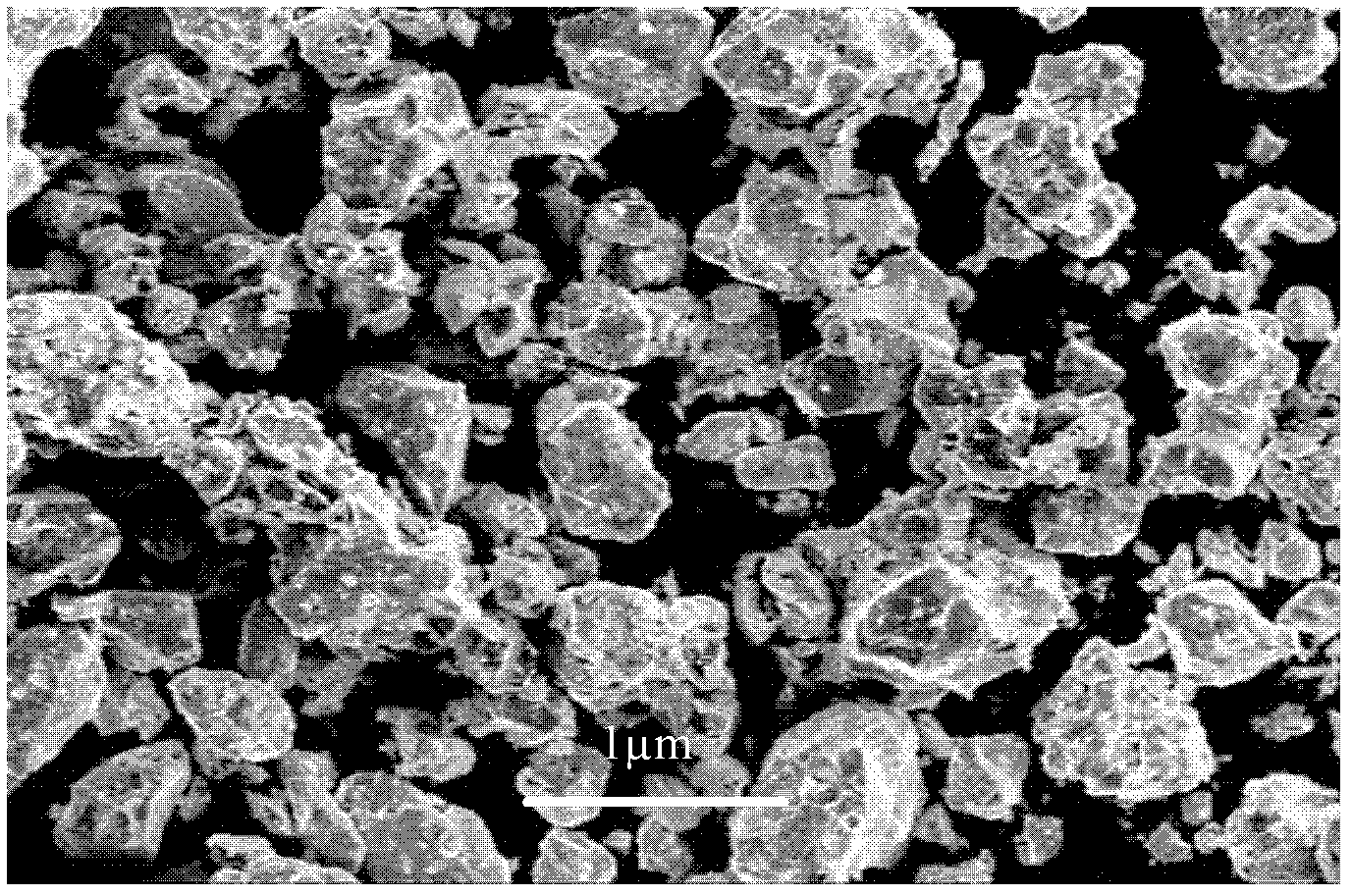

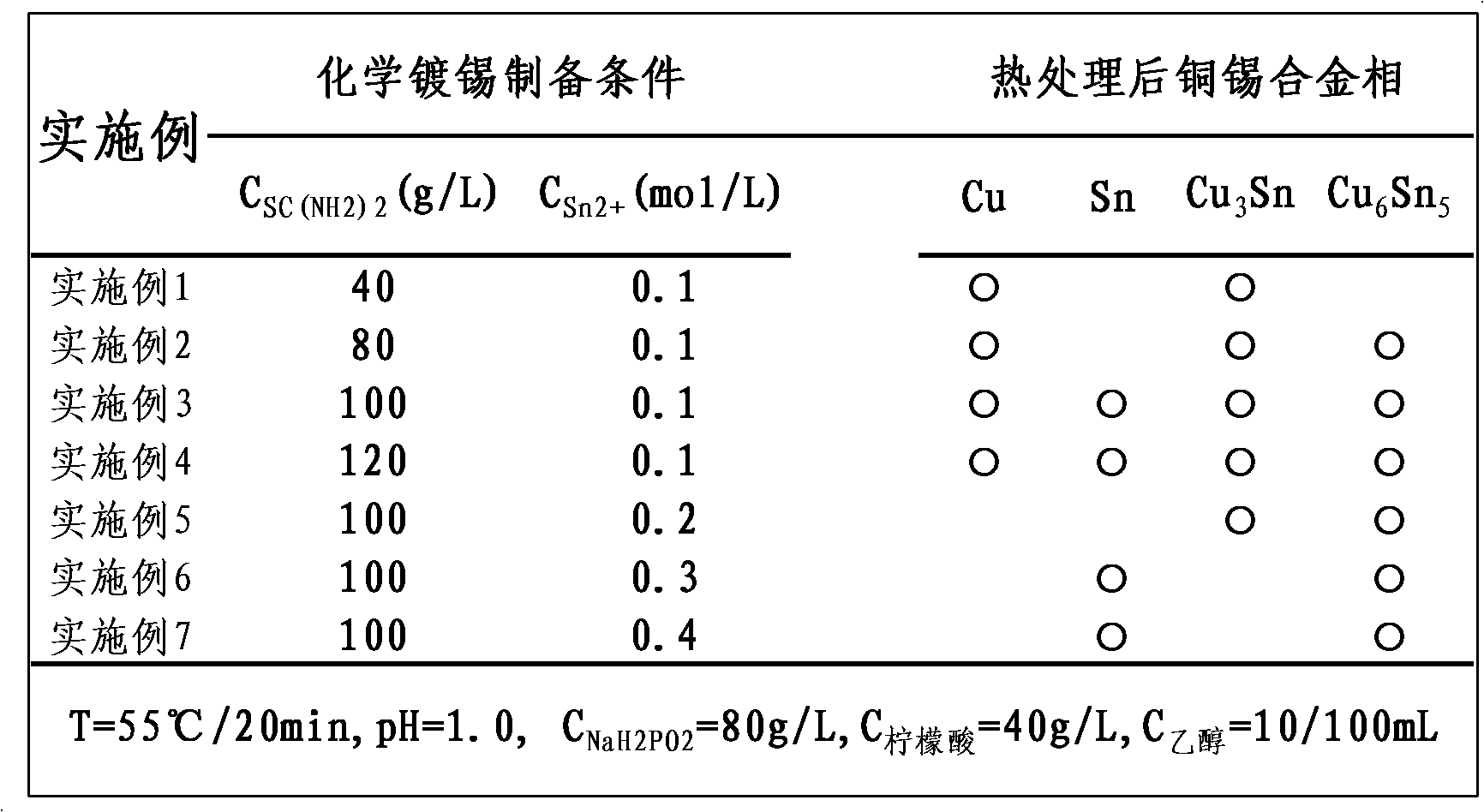

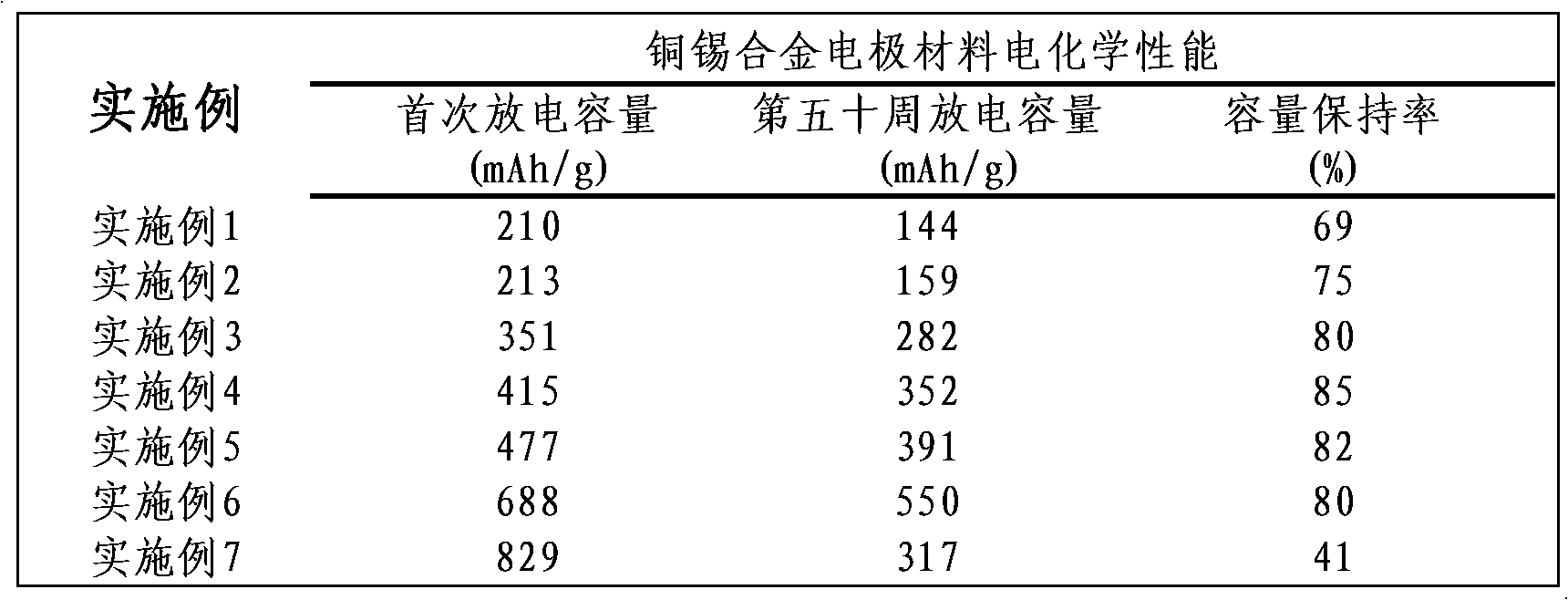

[0045] Put 100ml of distilled water into a 250ml beaker, add 4g of citric acid, 8g of sodium hypophosphite, 4g of thiourea, 0.01mol of stannous sulfate in sequence, add concentrated sulfuric acid dropwise to control the pH of the plating solution within 1.0, and heat the plating solution to 55°C . 1g of 0.1 micron copper powder was stirred and dispersed in 10ml of ethanol to prepare a copper powder suspension. Then, the suspension of copper powder is added into the electroless plating solution, and the reaction time is 20 minutes. After drying, copper-tin core-shell structure powder is obtained. The obtained tin-plated copper powder was heat-treated at 200° C. for 20 h to prepare copper-tin alloy powder.

Embodiment 2

[0047] Add 100ml of distilled water into a 250ml beaker, add 4g of citric acid, 8g of sodium hypophosphite, 8g of thiourea, 0.01mol of stannous sulfate in sequence, add concentrated sulfuric acid dropwise to control the pH of the plating solution within 1.0, and heat the plating solution to 55°C . 1g of 0.1 micron copper powder was stirred and dispersed in 10ml of ethanol to prepare a copper powder suspension. Then, the suspension of copper powder is added into the electroless plating solution, and the reaction time is 20 minutes. After drying, copper-tin core-shell structure powder is obtained. The obtained tin-plated copper powder was heat-treated at 200° C. for 20 h to prepare copper-tin alloy powder.

Embodiment 3

[0049] Put 100ml of distilled water into a 250ml beaker, add 4g of citric acid, 8g of sodium hypophosphite, 10g of thiourea, 0.01mol of stannous sulfate in sequence, add concentrated sulfuric acid dropwise to control the pH of the plating solution within 1.0, and heat the plating solution to 55°C . 1g of 0.1 micron copper powder was stirred and dispersed in 10ml of ethanol to prepare a copper powder suspension. Next, the suspension of copper powder was added into the electroless plating solution, and the reaction time was 10 minutes. After drying, copper-tin core-shell structure powder is obtained. The obtained tin-plated copper powder was heat-treated at 200° C. for 20 h to prepare copper-tin alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com