Production method of pearlite filter element

A production method, the perlite technology, is applied in the production field of perlite filter element, which can solve the problems such as the production cost of organic polymer materials which are not environmentally friendly, and achieve the effects of low production cost, good filtering effect and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

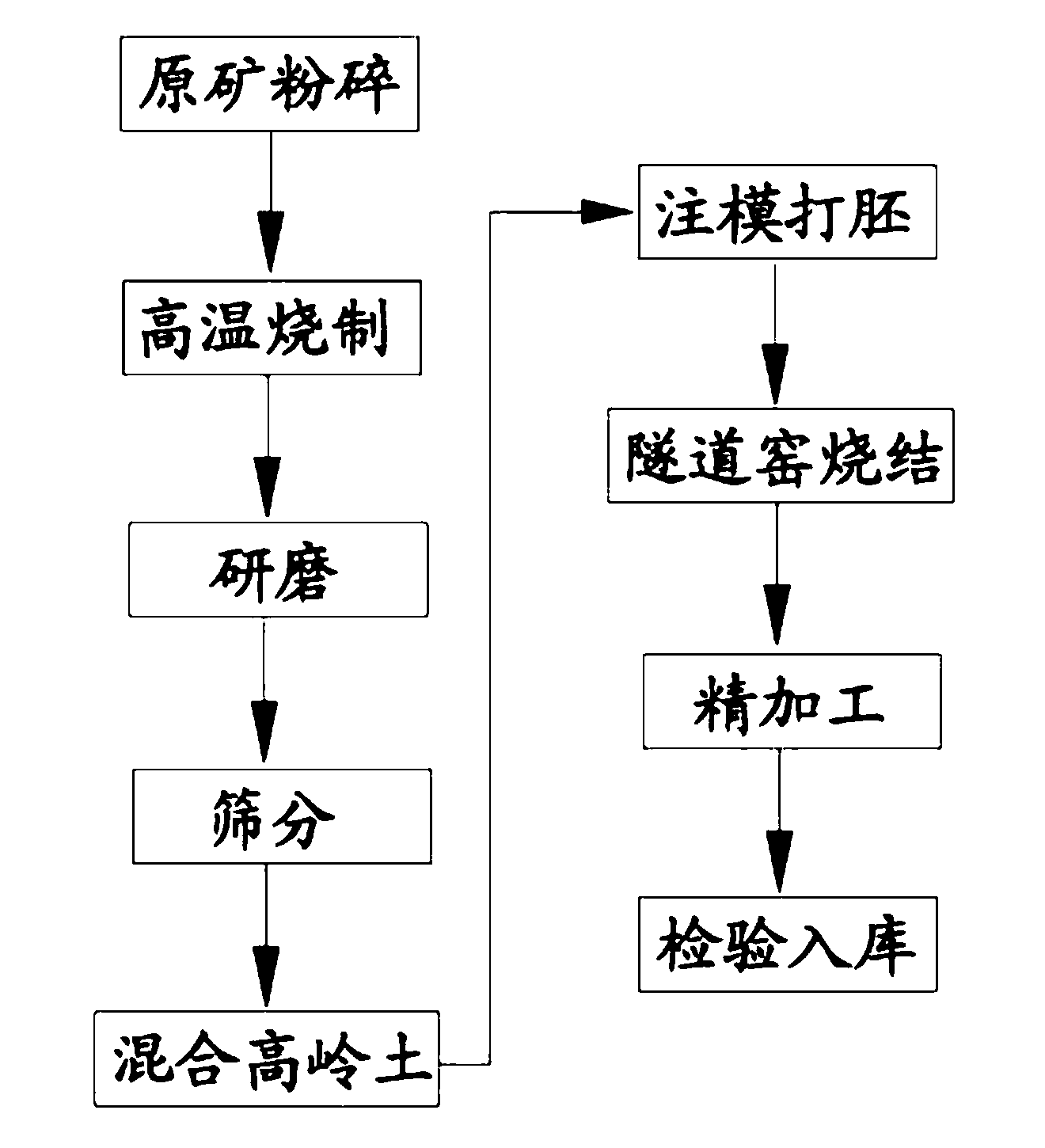

[0026] refer to figure 1 with 2 , the perlite filter element of the present embodiment is circular tube shape, and the whole filter element is formed by one-time processing of perlite and a certain proportion of kaolin, and its specific manufacturing process is as follows:

[0027] (1) Raw ore crushing: Perlite raw ore is a solid shale-like ore, which is collected by the mine and stored in a centralized manner. The collected perlite raw ore is sent to a crusher for crushing to obtain pearls with a particle size of 0.05-0.2 mm rock powder;

[0028] (2) High-temperature firing: The perlite powder obtained in step (1) is fired at a high temperature at 800-1000°C to expand the perlite powder;

[0029] (3) Grinding: send the perlite powder fired and expanded in step (2) into a grinder for grinding until the particle size is

[0030] (4) Sieving: Sieve the perlite powder after step (3), and take the perlite powder with a particle size between 0.001 and 0.01 mm for us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com