Production method for solution type acrylic solution slurry

A production method and a solution-type technology, applied in the field of solution-type acrylic solution slurry production, can solve the problems of complicated operation, complicated process, low safety, etc., and achieve good biodegradability, low process condition requirements, and high safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

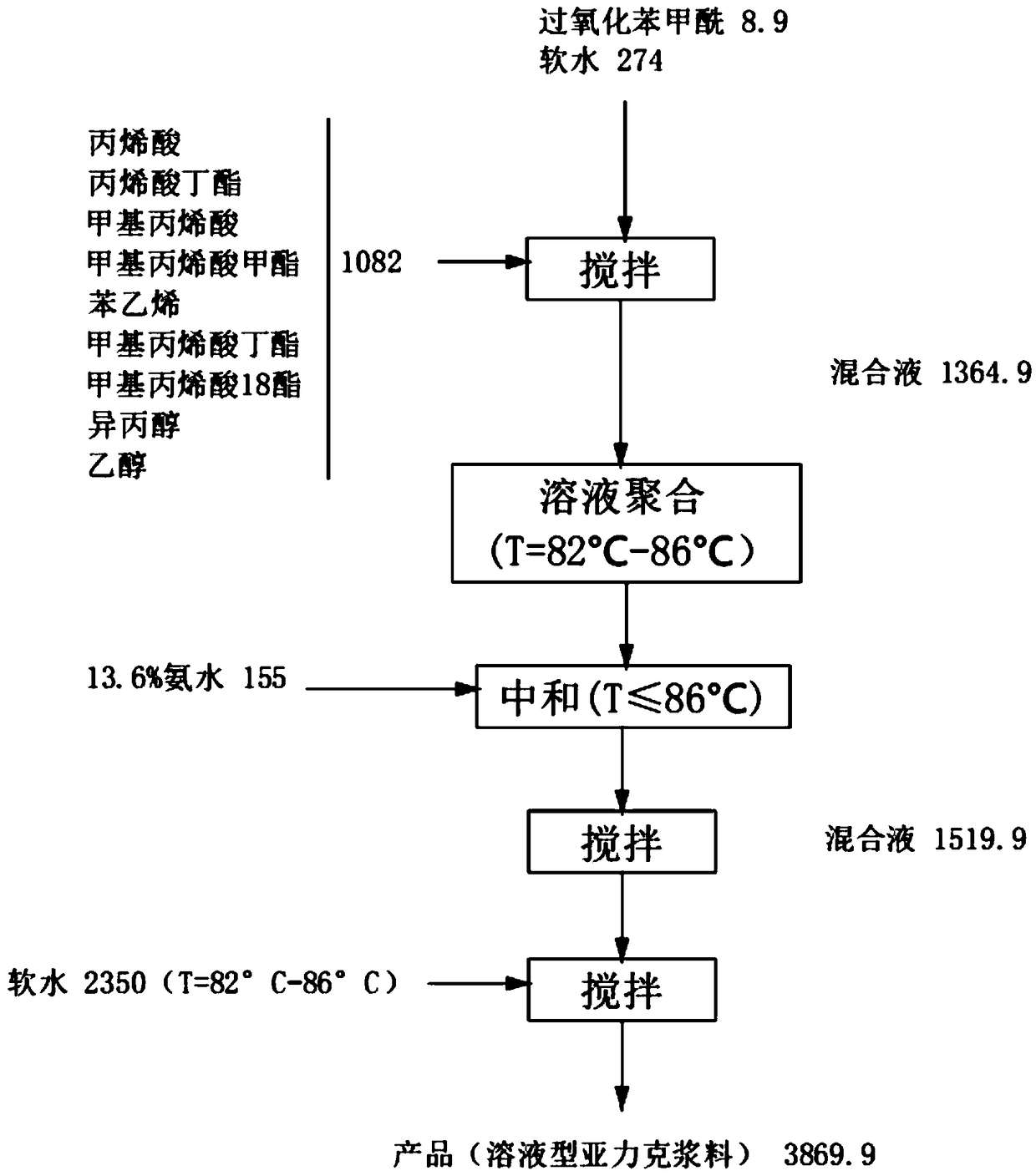

Method used

Image

Examples

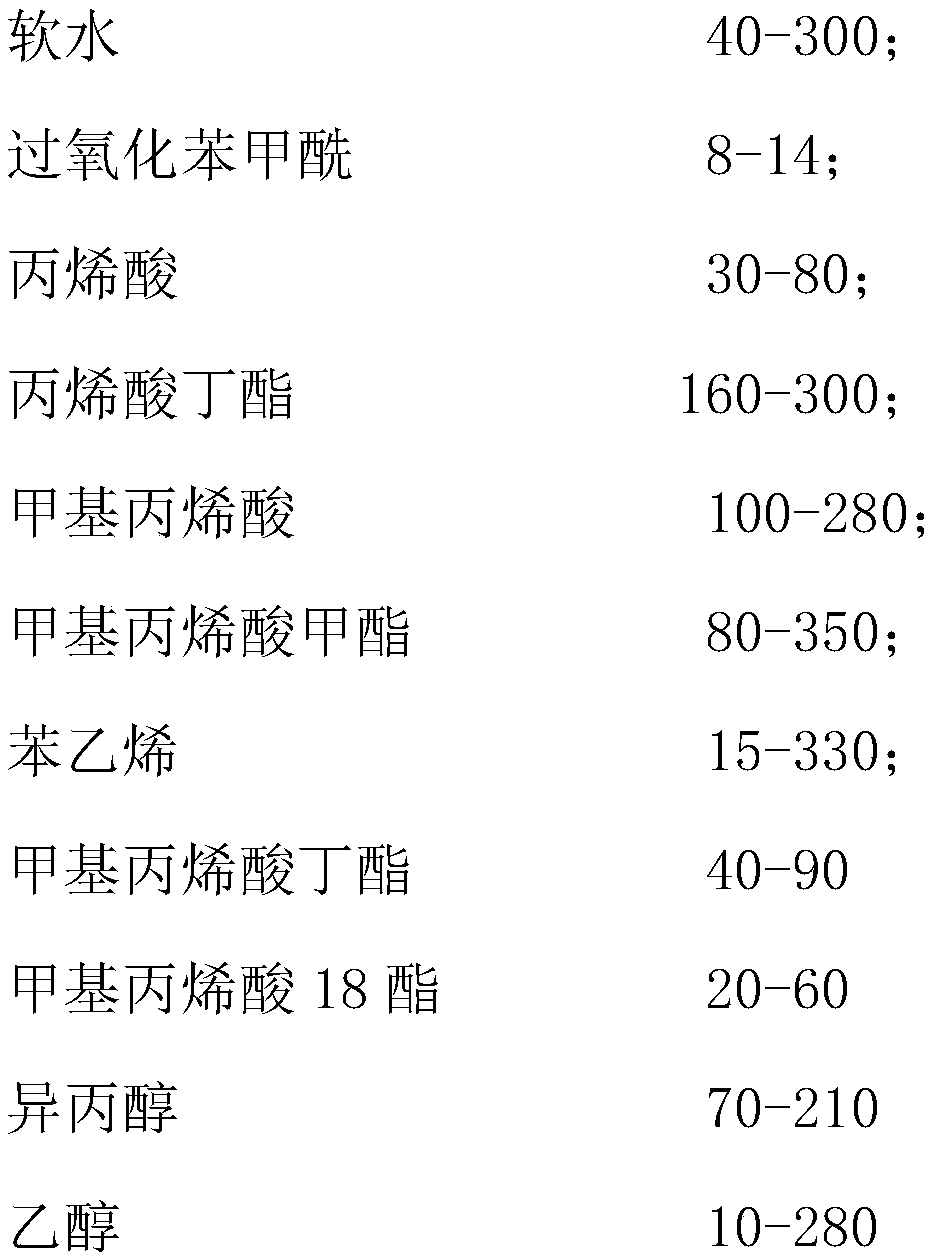

Embodiment 1

[0026] Soft water 40kg, benzoyl peroxide 14kg, acrylic acid 80kg, butyl acrylate 160kg, methacrylic acid 280kg, methyl methacrylate 80kg, styrene 330kg, butyl methacrylate 90kg, 18 methacrylate 20kg, iso Put 70kg of propanol and 280kg of ethanol into the reactor and stir, raise the temperature and control the temperature at 82-86°C, if the temperature does not rise after 4-5 hours of constant temperature, the polymerization reaction will end; then cool down, and when the temperature is below 86°C, use 140 parts by weight of ammonia water with a concentration of 12.4% is used to neutralize and adjust the pH value, then put into soft water with a temperature of 70-80° C., and stir evenly to obtain a slightly blue transparent liquid with a solid content of 26.8%-28.8% and a pH value of 6.5-7.8 finished product.

Embodiment 2

[0028] Soft water 57kg, benzoyl peroxide 11.8kg, acrylic acid 72.6kg, butyl acrylate 172kg, methacrylic acid 269.4kg, methyl methacrylate 90.6kg, styrene 312.4kg, butyl methacrylate 80.8kg, methyl Put 28kg of 18 acrylate, 85.6kg of isopropanol and 257kg of ethanol into the reactor and stir, heat up and control the temperature at 82-86°C. After 4-5 hours of constant temperature, the polymerization reaction will end if the temperature does not rise; When the temperature is below 86°C, use 152 parts by weight of 12.4% ammonia water to neutralize and adjust the pH value, then put in soft water with a temperature of 70-80°C, stir evenly to obtain a bluish transparent liquid with a solid content of 24.8%-25.8% , The finished product with a pH value of 6.6-8.0.

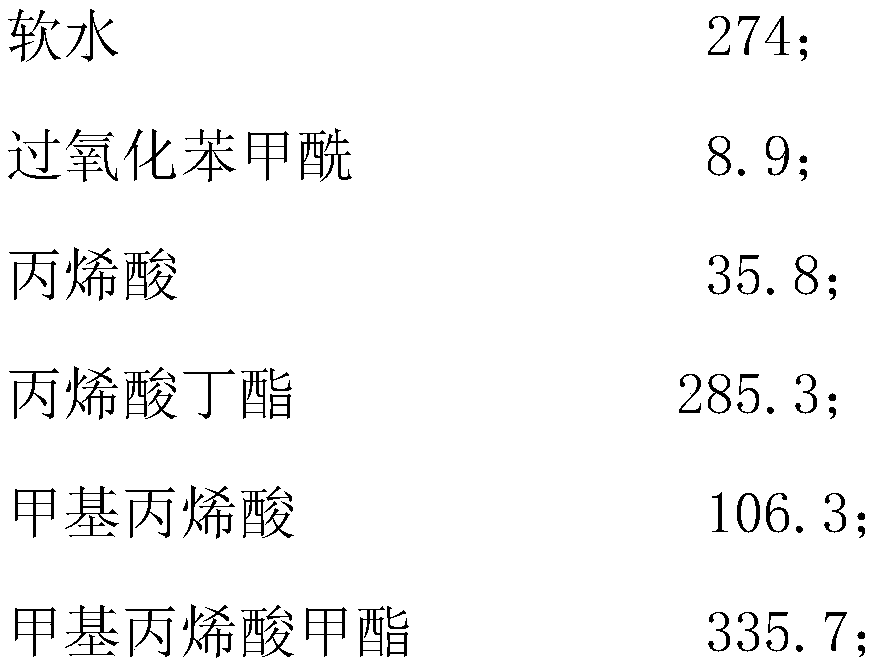

Embodiment 3

[0030] Soft water 274kg, benzoyl peroxide 9.1kg, acrylic acid 35.8kg, butyl acrylate 285.3kg, methacrylic acid 106.3kg, methyl methacrylate 335.7kg, styrene 18.1kg, butyl methacrylate 44.8kg, methyl Put 46.7kg of 18-acrylic acid ester, 192.5kg of isopropanol and 16.8kg of ethanol into the reaction kettle to stir, raise the temperature and control the temperature at 82-86°C, if the temperature does not rise after 4-5 hours of constant temperature, the polymerization reaction ends; then cool Cool down, when the temperature is below 86°C, use 140 parts by weight of 12.4% ammonia water to neutralize and adjust the pH value, then put in soft water with a temperature of 70-80°C, stir evenly to obtain a slightly yellowish transparent liquid with a solid content of 22.6% -23.6%, finished product with a pH value of 8.0-9.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com