Method for testing melting speed of continuous casting powder

A technology of continuous casting mold flux and melting rate, applied in the field of steelmaking, can solve problems such as difference in measurement results, and achieve the effect of low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

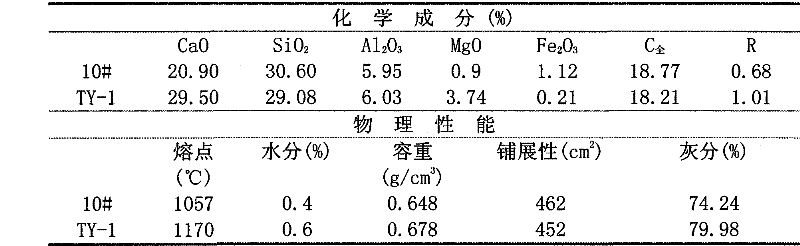

Method used

Image

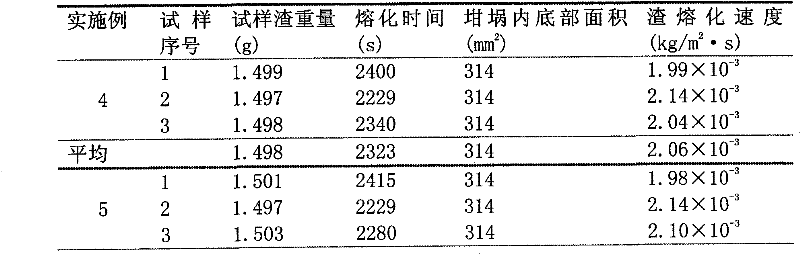

Examples

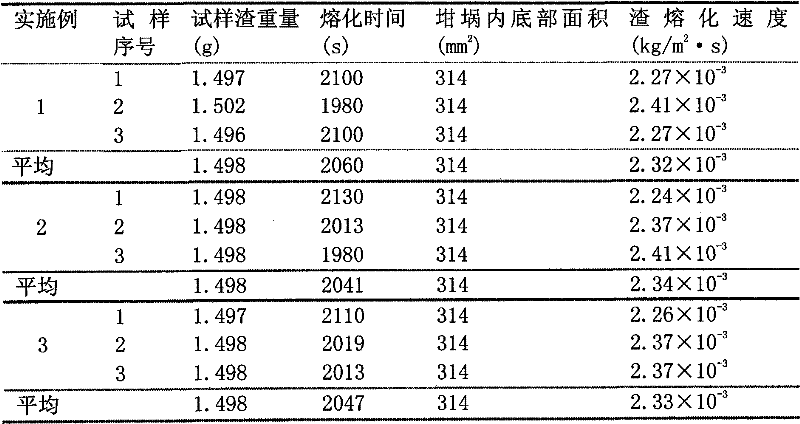

Embodiment 1

[0024] A method for testing the melting rate of continuous casting mold flux, characterized in that:

[0025] (a) Use a balance to weigh three mold powder samples, each of which is: 1.497 grams, 1.502 grams, and 1.496 grams;

[0026] (b) When heating up, put the crucible into the furnace, raise the temperature of the furnace to 1350°C, the temperature fluctuation error is ±20°C, and keep the temperature constant for 20 minutes;

[0027] (c) Take out the crucible from the furnace, quickly add a sample of the mold flux to be tested into the crucible and put it into the furnace together, and start the stopwatch at the same time to mark the time, that is, from the time when the sample is put into the furnace to when the last dark spot of the sample turns bright The time required to record the complete melting of the sample is 2100 seconds;

[0028] (d) Measure and calculate the surface area of the inner bottom of the crucible to be 314mm 2 , according to the formula MR=W / τ·A, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com