Petroleum drilling additive high temperature-resistant filtrate reducer and preparation method thereof

A technology of oil drilling and fluid loss control agent, which is applied in the field of oil drilling additives and fluid loss control agents for drilling fluids. It can solve the problems of reducing the fluid loss of drilling mud and achieve low fluid loss and good temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

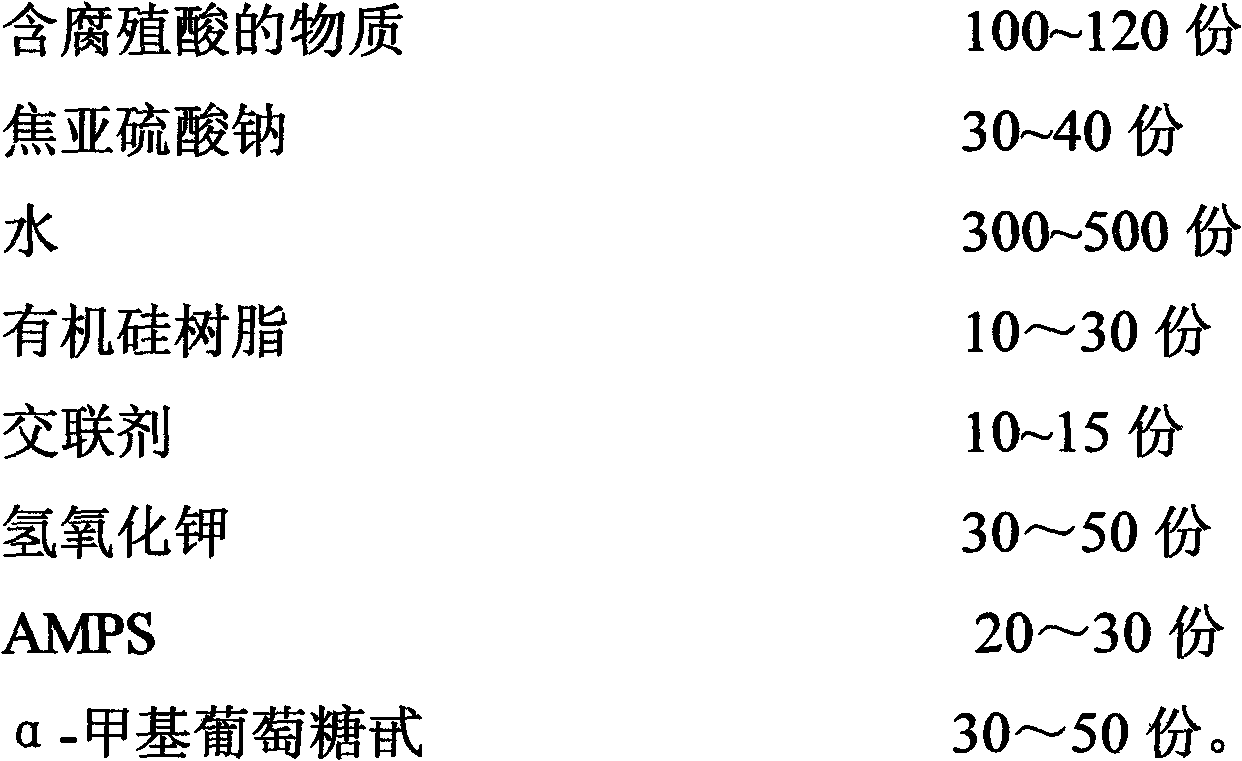

[0023] Embodiment 1: the fluid loss reducer of the present invention (the described petroleum drilling aid anti-high temperature fluid loss reducer) is made from the raw materials of following weight ratio:

[0024] Lignite (or peat or weathered coal, that is, substances containing humic acid) 360 kg, sodium metabisulfite 90 kg, water 1500 kg, silicone resin 60 kg, crosslinking agent (formaldehyde) 45 kg, potassium hydroxide 90 kg, AMPS (2-acrylamido-2-methylpropanesulfonic acid) 90 kg, α-methyl glucoside (methyl glucoside) 150 kg.

[0025] The preparation method of the described petroleum drilling aid anti-high temperature fluid loss reducer, it (sequentially) comprises the following steps: (1), water, potassium hydroxide, lignite (or peat or weathered coal), sodium pyrosulfite Add it into the stirred reactor, seal it, raise the temperature to 160°C, react for 2 hours, and cool down to below 60°C (such as 55°C). This step improves the temperature resistance and viscosity redu...

Embodiment 2

[0026] Embodiment 2: the fluid loss reducer of the present invention (the described petroleum drilling aid anti-high temperature fluid loss reducer) is made from the raw materials of following weight ratio:

[0027] lignite or peat or weathered coal (substances containing humic acid) 240 kg or 300 kg, sodium metabisulfite 150 kg or 240 kg, water 900 kg or 1200 kg, silicone resin 30 kg or 150 kg, crosslinking agent (formaldehyde ) 6 kg or 30 kg, potassium hydroxide 120 kg or 150 kg, AMPS (2-acrylamido-2-methylpropanesulfonic acid) 30 kg or 120 kg, α-methyl glucoside (methyl glucoside) 60kg or 240kg.

[0028] The preparation method of the described petroleum drilling aid anti-high temperature fluid loss reducer, it (sequentially) comprises the following steps: (1), add water, potassium hydroxide, lignite or peat or weathered coal, sodium pyrosulfite according to the above weight and stir In a reaction kettle, seal it, heat up to 165°C (or 155°C), react for 3 hours (or 2.5 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com