Horizontal continuous casting device and method for high-conductivity and high-strength copper alloy round bar

An alloy rod and horizontal technology, which is applied in the field of preparing chromium-zirconium copper alloy, can solve problems such as cracks in billet and inability to cast chromium-zirconium-copper alloy billet, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

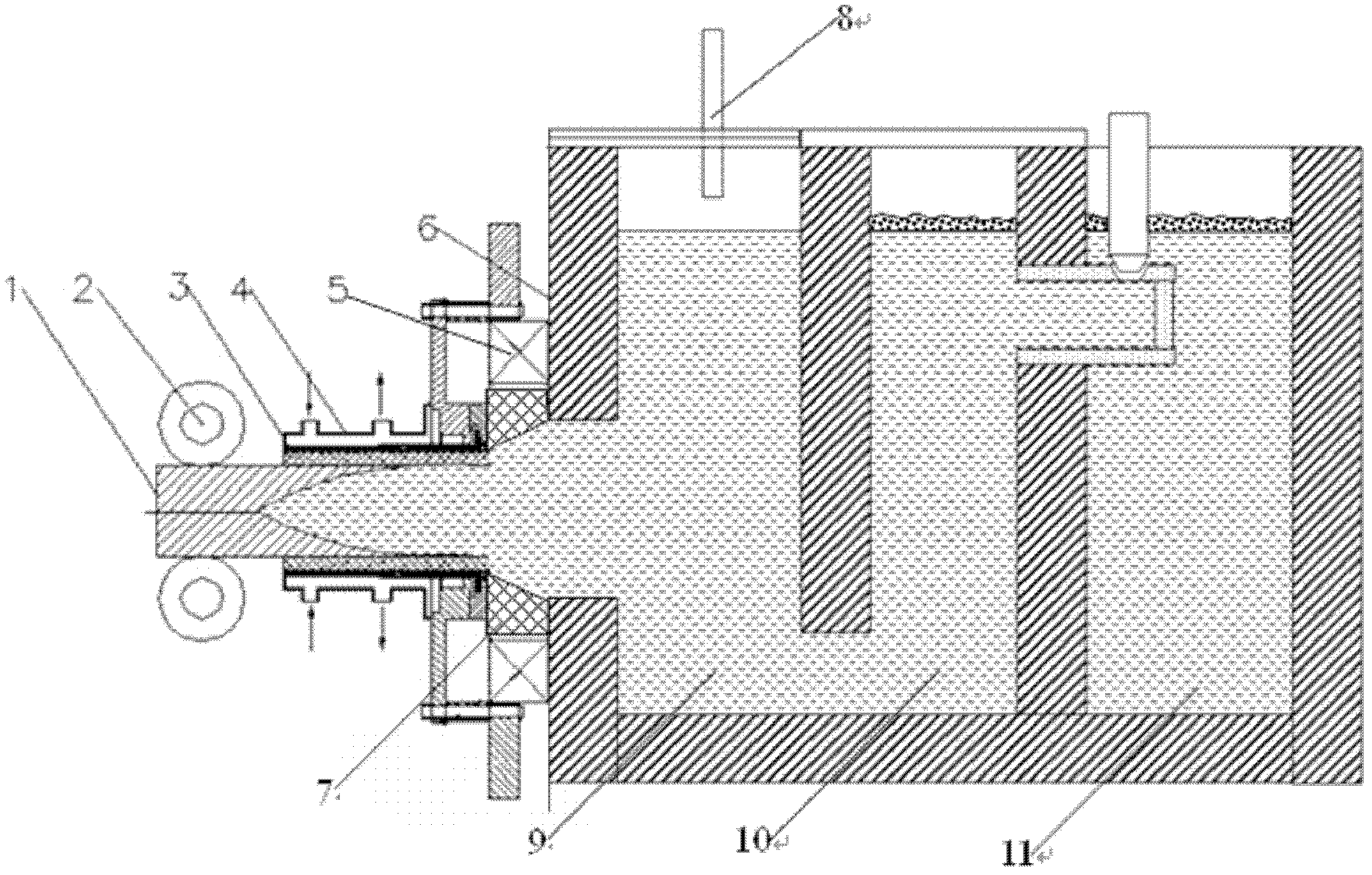

[0019] The casting crystallizer is installed on the horizontal continuous casting holding furnace 6, and the graphite lining 3 is a hollow mold to realize the shape casting of the billet. After the industrial copper plate is melted in the smelting furnace 11, appropriate alloys are added, and it flows into the refining furnace 10. After adjusting the chemical composition in the refining furnace 10, it enters the holding furnace 9. When the melt temperature reaches 1255-1260 ° C, it starts casting and controls the cooling device. The flow in 4 reaches 1.9m 3 / h, control the traction system 2 so that the casting speed is 108mm / min, and the electromagnetic parameters are 50A, 30Hz. In the normal production process, chromium and zirconium master alloys need to be added regularly and quantitatively. Using this process, it is possible to continuously and stably produce chrome-zirconium copper billets with a diameter of Φ87mm and a length of 45m. There are no cracks on the surface, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com