Multi-port continuous casting equipment

A technology with multiple nozzles and equipment, which is applied in the field of metallurgical continuous casting, can solve problems such as increased equipment cost, difficulty in controlling the flow of molten steel, and complex flow control equipment in the tundish, and achieves the effects of simple equipment, convenient control, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

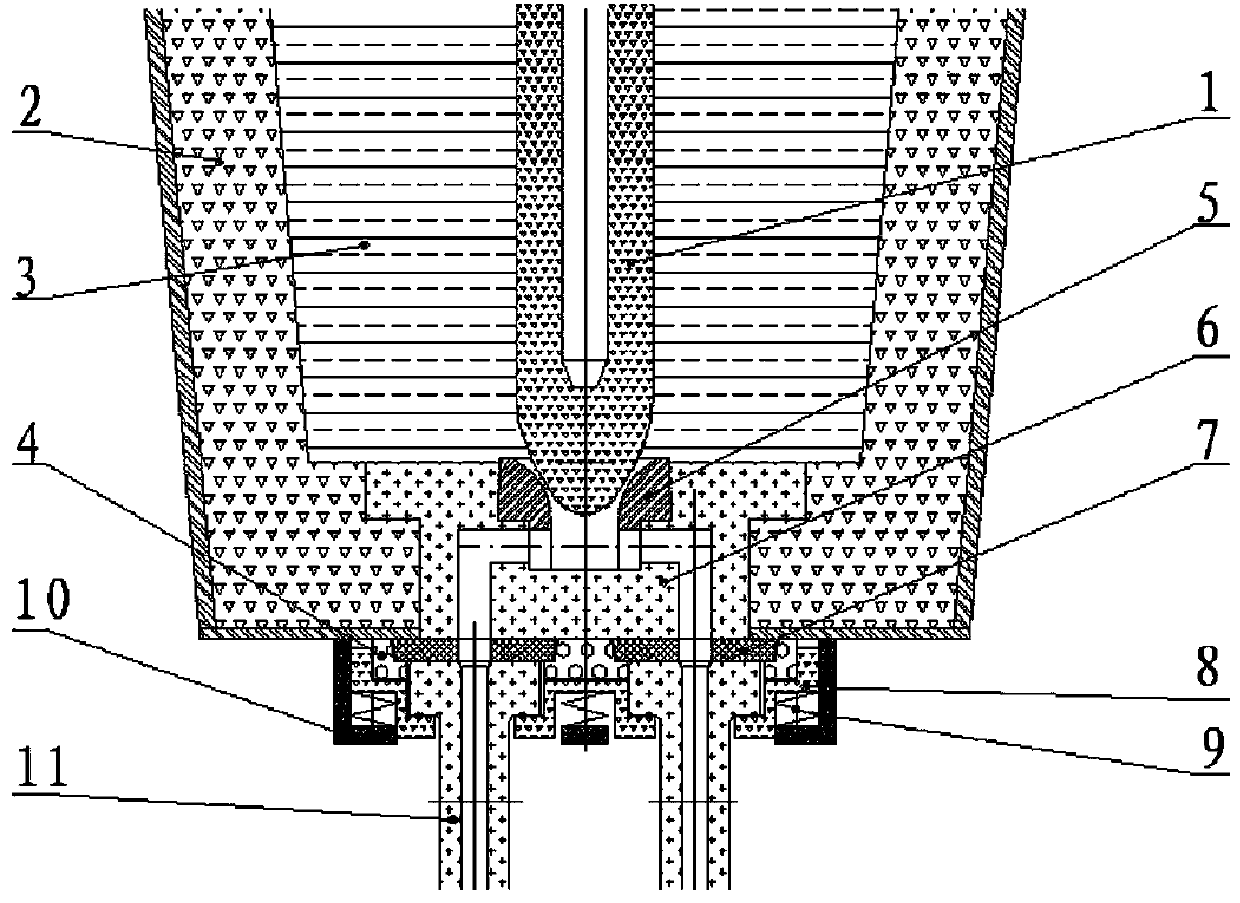

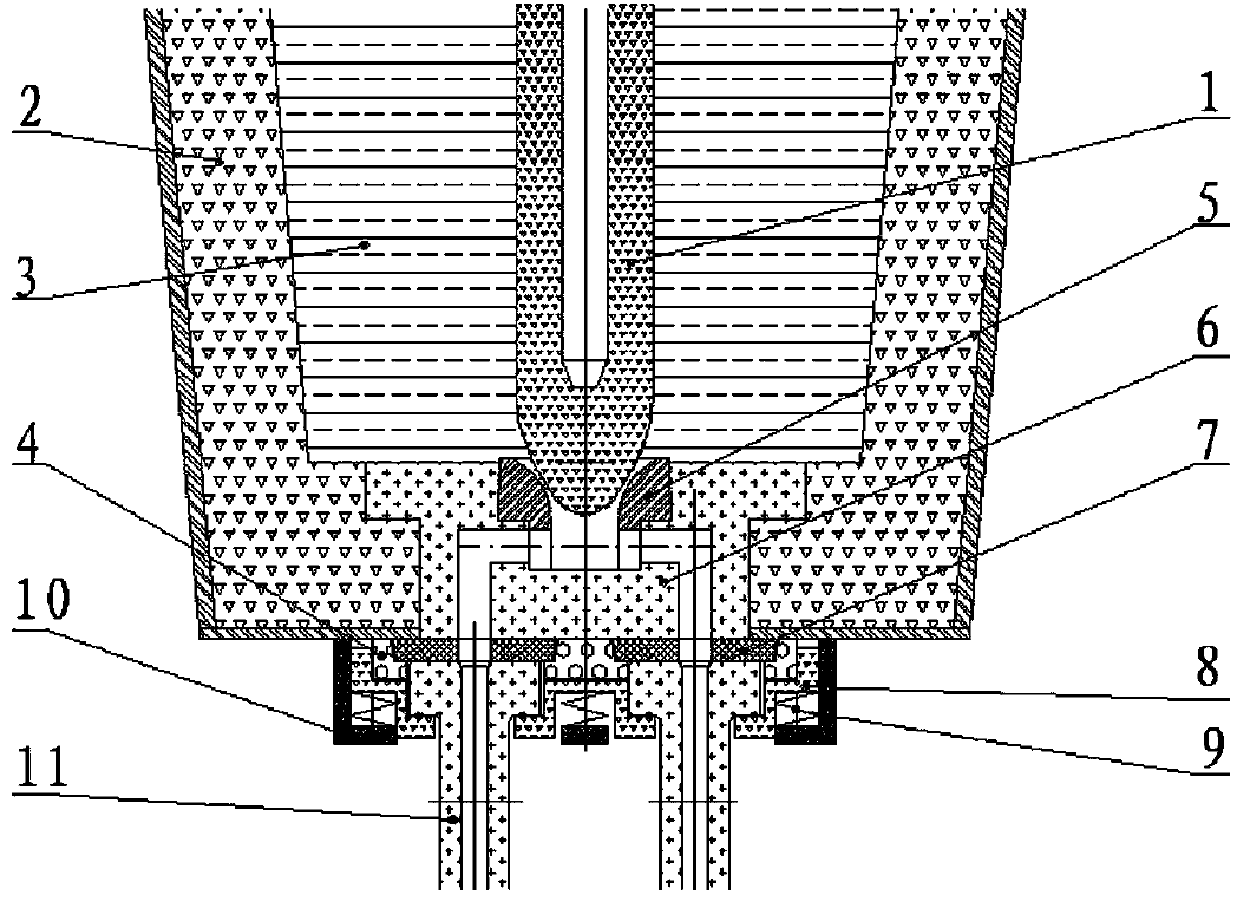

[0028] The present invention is a multi-nozzle casting equipment for a continuous casting machine, comprising a stopper 1, a tundish 2, molten steel 3, an inner bracket 4, an upper nozzle 5, a porous brick 6, a movable insert plate 7, a lifting bracket 8, and a compression spring 9 , Outer support 10, nozzle 11.

[0029] The tundish 2 contains liquid steel 3. The stopper rod 1 is inserted into the tundish, located on the upper part of the upper nozzle 5. The bottom of the stopper rod 1 matches the contact surface of the upper nozzle 5. The lower stopper rod 1 can completely block the upper nozzle. The nozzle is used to cooperate with the upper nozzle 5 to control the flow of molten steel. Have the embedding hole that cooperates with upper nozzle 5 above the perforated brick 6, make it fixed. The porous brick 6 is embedded in the bottom of the tundish, and is integrated with the tundish through a refractory material. A molten steel channel is provided in the porous brick 6 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com