Chromium-free passivation liquid applied to surface of zinc-coated layer

A technology of chromium-free passivation and galvanized layer, applied in the direction of metal material coating process, etc., can solve problems such as biological toxicity, and achieve the effect of simple passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The mixture of 20g cerium nitrate and ammonium phosphomolybdate (weight ratio is 1: 1.7), 2g phytic acid, 2g ammonium persulfate, 50g aminopropyltriethoxysilane modified nano-silica, 10g vinyltrimethoxy Silane, 10g epoxypropyltriethoxysilane, 50g silicone modified acrylate emulsion, add water to prepare 1 liter of passivation solution, adjust pH to 1 with 6M nitric acid, to obtain light red passivation solution.

[0032] When in use, it is diluted with deionized water according to the ratio (volume ratio passivation solution: water=1:5-10) to obtain the passivation solution working solution.

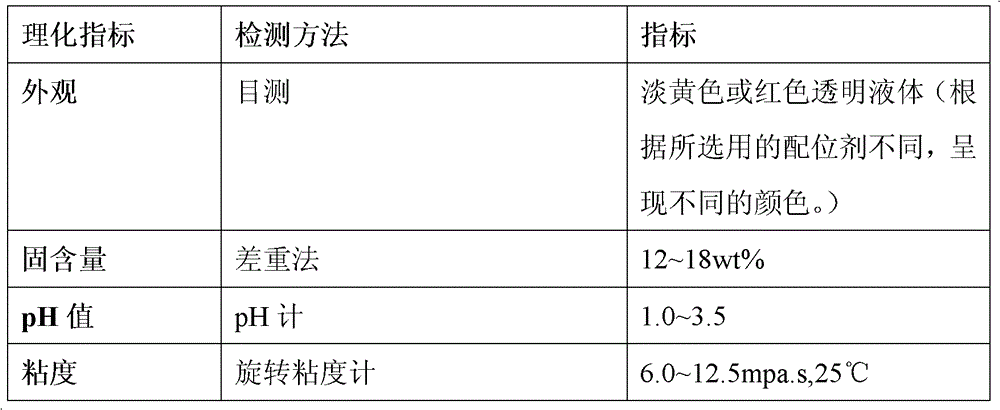

[0033] Take the galvanized parts out of the electroplating tank, rinse them in 3wt% dilute nitric acid, rinse twice in deionized water, and then put them into the prepared passivation working solution. The passivation time is 20-60s , after leaving the tank, dry it at 100°C for 5-15 minutes. The properties of the passivated galvanized layer are as follows:

[0034]

[0035] U...

Embodiment 2

[0037] 35g mixture of cerium nitrate and ammonium phosphomolybdate (weight ratio is 1:1.9), 4g tartaric acid, 3.5g ammonium persulfate, 40g aminopropyltriethoxysilane modified nano-zirconia, 20g aminopropyltriethoxy Base silane, 5g epoxypropyltriethoxysilane, 40g silicone-modified acrylic emulsion, add water to prepare 1 liter of passivation solution, adjust the pH to 1 with 6M nitric acid, and obtain a light red passivation solution. The using method of passivation solution is the same as embodiment 1. The properties of the passivated galvanized layer are as follows:

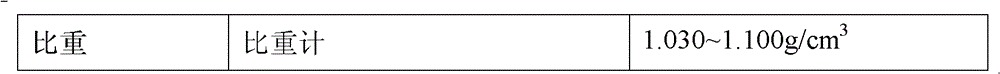

[0038] performance item

[0039] (white rust area)

[0040] Use hexavalent chromium passivation solution and trivalent chromium passivation solution to directly passivate the same object as a control.

Embodiment 3

[0042] The mixture of 50g lanthanum nitrate and ammonium phosphomolybdate (weight ratio 1: 2), 5g phytic acid, 4g ammonium persulfate, 30g ureidopropyltrimethoxysilane modified nano-silica and epoxypropyltriethyl The mixture of oxysilane-modified nano-zirconia (weight ratio is 2:1), 25g epoxypropyltriethoxysilane, 30g organic silicon-modified acrylate emulsion, add water to prepare 1 liter, and use 6M nitric acid Adjust the pH to 1 to obtain a light yellow passivation solution. The using method of passivation solution is the same as embodiment 1. The properties of the passivated galvanized layer are as follows:

[0043]

[0044] Use hexavalent chromium passivation solution and trivalent chromium passivation solution to directly passivate the same object as a control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com