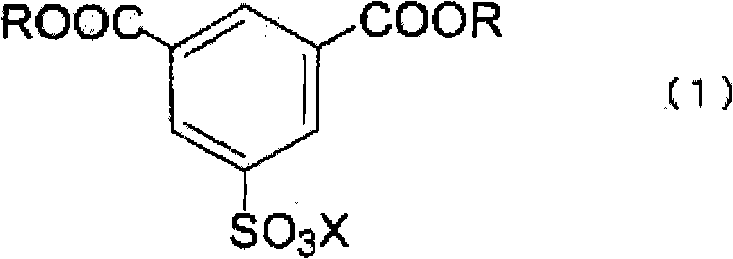

Cationic dyeable polyester and application thereof

A cationic dye and polyester technology, applied in the direction of conjugated synthetic polymer artificial filament, etc., can solve the problems of low physical properties of polyester masterbatch and polyester, low production efficiency of dyeable polyester, etc., and achieve low production cost, Excellent dyeing performance and high flexibility of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

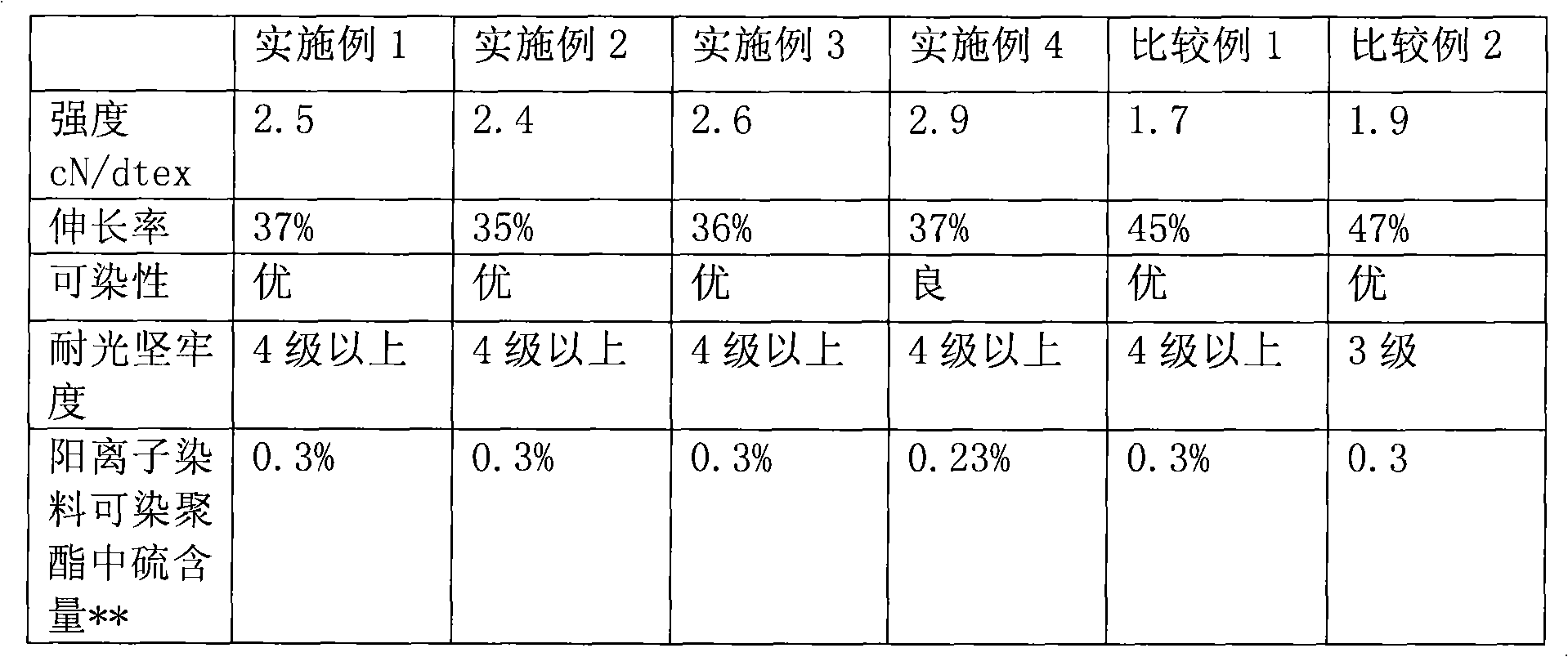

Embodiment 1

[0030] Take 13.9 parts by weight of dimethyl terephthalate, 10.4 parts by weight of ethylene glycol and 1.2 parts by weight of dimethyl isophthalate-5-sodium sulfonate, add them to the reaction kettle with heating and stirring, and then add After 0.3% by weight of manganese acetate and 2.4% by weight of lithium acetate relative to the polyester, the temperature is gradually raised to carry out the transesterification reaction, and methanol is gradually distilled out. When the distilled methanol amount reaches more than 95% of the theoretical amount, the transesterification reaction is completed. , move the reaction product to a polymerization kettle, add 0.45 parts by weight of polyethylene glycol with a molecular weight of 1000, and add phosphorus compound trimethyl phosphate, antioxidant IR1010, antifoaming agent silicone oil, etc., and then gradually heat up to 280-290 degree, and reduce the pressure to below 100Pa for 1 to 3 hours to react for 1 to 3 hours. After reaching t...

Embodiment 2

[0033] During the preparation of cationic dye-dyeable polyester masterbatch, the content of sulfur element in the polyester masterbatch was increased to 1.5wt% by changing the amount of dimethyl isophthalate-5-sodium sulfonate, and polyethylene was no longer added. Diol, but add 3wt% sodium dodecylbenzene sulfonate as a compatibilizer, in the process of blending the polyester masterbatch and the matrix polyester, the ratio of the polyester masterbatch to the matrix polyester is 1 : 4 to carry out, other steps are with embodiment 1.

Embodiment 3

[0035] During the preparation of cationic dye-dyeable polyester masterbatch, the content of sulfur element in the polyester masterbatch was increased to 1.2wt% by changing the amount of dimethyl isophthalate-5-sodium sulfonate, and polyethylene Glycol, but add the sodium dodecylbenzenesulfonate of 2.8wt% as compatibilizer, in the process that polyester masterbatch and matrix polyester are blended, the ratio of masterbatch and matrix polyester is 1: 3, other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com