Environmentally-friendly storage-stable polyurethane composition for reaction injection molding and preparation method thereof

A technology of injection molding and composition, which is applied in the field of polyurethane, can solve the problems that the molding cycle is less than 1 minute, and the tin catalyst is difficult to meet the environmental protection index, and achieve the effect of short curing and demolding time, good compactness and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

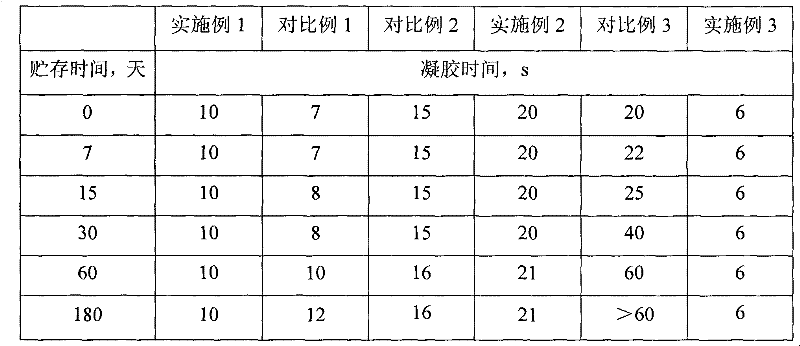

Examples

preparation example Construction

[0032] Examples The preparation method of the delayed amine catalyst is as follows: mix 1 part of triethylenediamine with 2 parts of ethylene glycol or diethylene glycol, heat to 70-80 ° C and stir to dissolve, then add 20% by mass of salicylic acid , After heating at 80°C and stirring for 1 h, the delayed catalyst was obtained.

[0033] The concrete process of embodiment composition A, B component preparing PU-RIM material by RIM machine is as follows:

[0034] ①Feeding: according to the formula, premix component A of the composition evenly and add it to the storage tank of component A of the high-pressure injection machine, and then weigh a certain amount of component B of the composition and add it to the storage tank of component B;

[0035] ②Injection: Set the material temperature of component A to 20-40°C, component B at 20-40°C, and the injection pressure at 15±3MPa. After starting the injection, inject the reaction material, which has been preheated to 50-50°C, through...

Embodiment 1

[0039] Component A: 330N: 79.6 parts; 1,4-butanediol: 13.4 parts; carbon black: 2 parts; 2-(2'-hydroxy-5'-methylphenyl) benzotriazole: 3.6 parts ; Parts of bis(3,5-di-tert-butyl-4-hydroxyphenyl)sulfide: 1.2 parts; Bismuth neodecanoate: 0.09 parts; Delayed amine catalyst: 0.1 parts. Add each component into the reaction vessel, stir evenly and then discharge.

[0040]Component B: carbodiimide-modified diphenylmethane diisocyanate (NCO mass fraction 29%-30%): 90 parts; polyoxypropylene diol with a molecular weight of 2000: 10 parts. NCO mass fraction is 26.2%.

[0041] The reaction ratio of A and B is 100:58.5.

Embodiment 2

[0051] Component A: 330N: 77.35 parts; Ethylene glycol: 20.5 parts; Carbon black: 2 parts; Bismuth neodecanoate: 0.06 parts; Delayed amine catalyst: 0.08 parts. Add each component into the reaction vessel, stir evenly and then discharge.

[0052] Component B: uretonimine modified diphenylmethane diisocyanate (NCO mass fraction: 29-30%): 90 parts; polyoxypropylene diol with a molecular weight of 2000: 10 parts. NCO mass fraction is 26.4%.

[0053] A, B reaction ratio is 100:120.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com