Compound Omeprazole tablets and preparation method thereof

A technology of omeprazole tablets and omeprazole, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, pill delivery, etc., can solve the problem of high energy consumption and unsuitable Large-scale industrial production, large amount of antacids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Prescription:

[0023] Omeprazole

2kg

75kg

34.3kg

Titanium dioxide

1kg

5% sodium carboxymethylcellulose solution

50L

Crospovidone

2kg

Sodium stearyl fumarate

0.5g

A total of 100,000 pieces were made

[0024] 2. Process steps:

[0025] Omeprazole and titanium dioxide powder are dispersed in 5% sodium carboxymethylcellulose aqueous solution, after stirring evenly, carry out spray drying with spray drier, obtain dry omeprazole polymer material fusion, standby (spray condition: Inlet air temperature: 125°C; outlet air temperature: 76°C; feeding rate: 0.5L / min). Mix omeprazole polymer material fusion, sodium bicarbonate, magnesium hydroxide, croscarmellose sodium and sodium stearyl fumarate through a 100-mesh sieve, mix evenly and directly compress into tablets with a hardness of 10 -16kg.

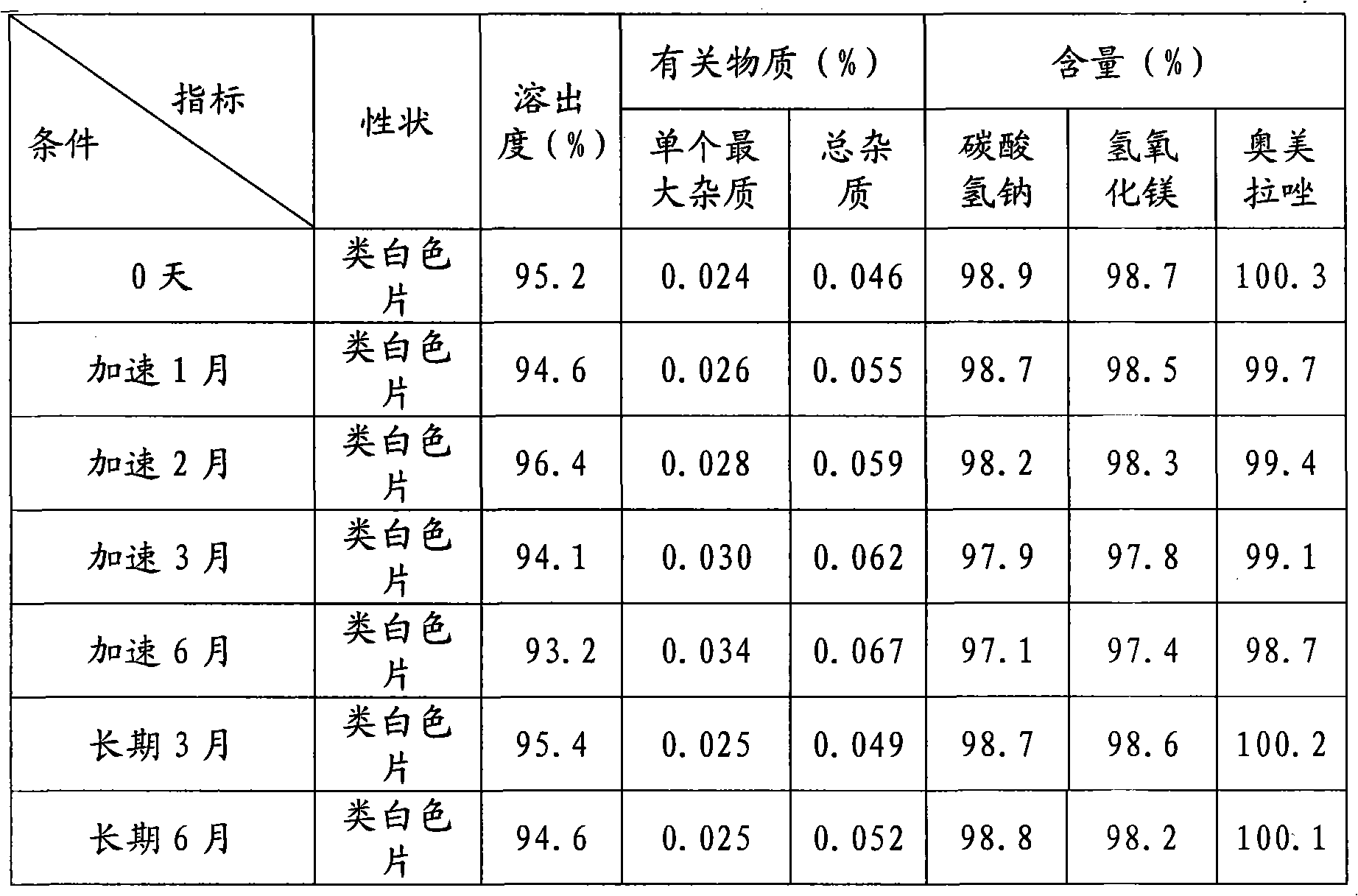

[0026] Influencing factors and stability...

Embodiment 2

[0041] 1. Prescription:

[0042] Omeprazole

2kg

100kg

magnesium hydroxide

20kg

Titanium dioxide

1kg

8% hypromellose solution

50L

2kg

Sodium stearyl fumarate

0.5g

A total of 100,000 pieces were made

[0043] 2. Process steps:

[0044] Omeprazole and titanium dioxide powder are dispersed in 5% hypromellose aqueous solution, after stirring evenly, carry out spray drying with spray drier, promptly obtain dry omeprazole polymer material fusion, standby (spray condition: advance Air temperature: 125°C; outlet air temperature: 76°C; feeding rate: 0.5L / min). Mix omeprazole polymer material fusion, sodium bicarbonate, magnesium hydroxide, croscarmellose sodium starch sodium and sodium stearyl fumarate through a 100-mesh sieve, mix evenly and directly compress into tablets with a hardness of 10- 16kg.

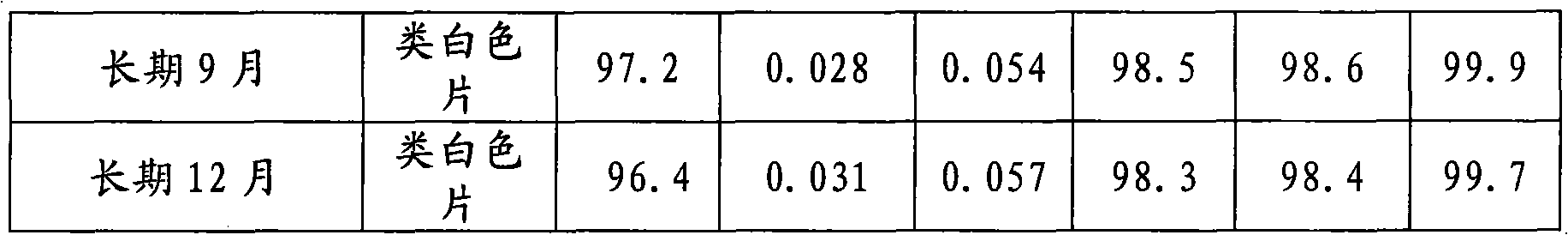

[0045] Investigation of influencin...

Embodiment 3

[0055] 1. Prescription:

[0056] Omeprazole 4kg

[0057] Sodium bicarbonate 500kg

[0058] Magnesium hydroxide 650kg

[0059] Titanium dioxide 3kg

[0060] 8% hydroxypropyl cellulose solution 25L

[0061] Croscarmellose Sodium 4kg

[0062] Sodium stearyl fumarate 1kg

[0063]

[0064] A total of 100,000 pieces were made

[0065] 2. Process steps:

[0066] Omeprazole and titanium dioxide powder are dispersed in 8% hydroxypropyl cellulose aqueous solution, carry out spray drying with spray drier after stirring, obtain dry omeprazole polymer material fusion (spray condition: inlet air temperature: 125°C; air outlet temperature: 76°C; feeding rate: 0.5L / min), for standby. Mix omeprazole polymer material fusion, sodium bicarbonate, magnesium hydroxide, croscarmellose sodium starch sodium and sodium stearyl fumarate through a 100-mesh sieve, mix evenly and directly compress into tablets with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com