Method for manufacturing semiconductor integrated device

A technology of integrated devices and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of waste of materials, process steps, and low process integration, so as to improve process integration, prevent over-polishing, and save Effect of process steps and consumption of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

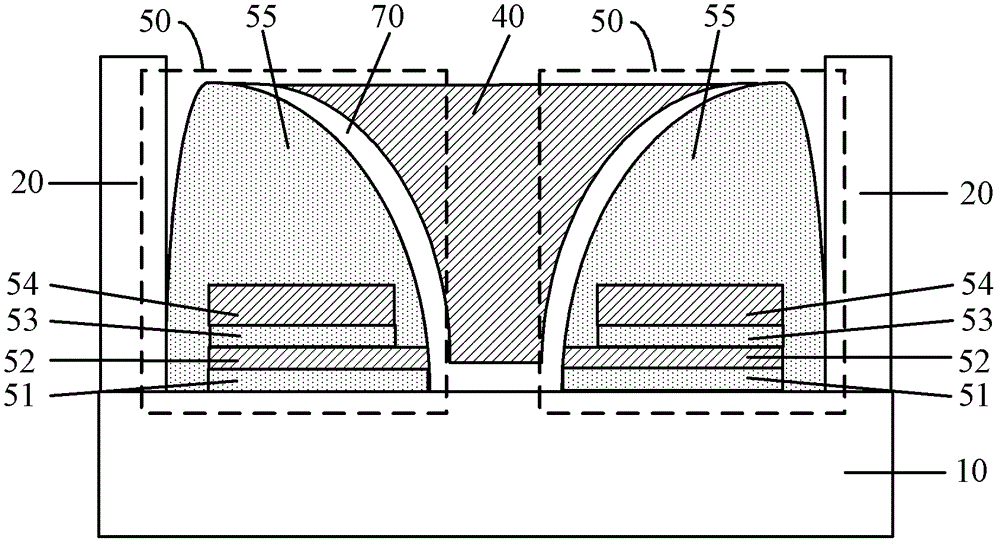

[0030] When forming split-gate flash memory and other semiconductor devices such as MOS transistors, polysilicon resistors, and polysilicon capacitors on the same semiconductor substrate, the manufacturing process of the formed MOS transistors, polysilicon resistors, capacitors and other devices includes the formation of polysilicon layers. The polysilicon layer is etched. If the polysilicon layer deposited in the process of forming the split-gate flash memory is etched away, another layer of polysilicon layer is deposited to form devices such as MOS transistors, polysilicon resistors, and polysilicon capacitors. steps and waste the raw materials for polysilicon deposition.

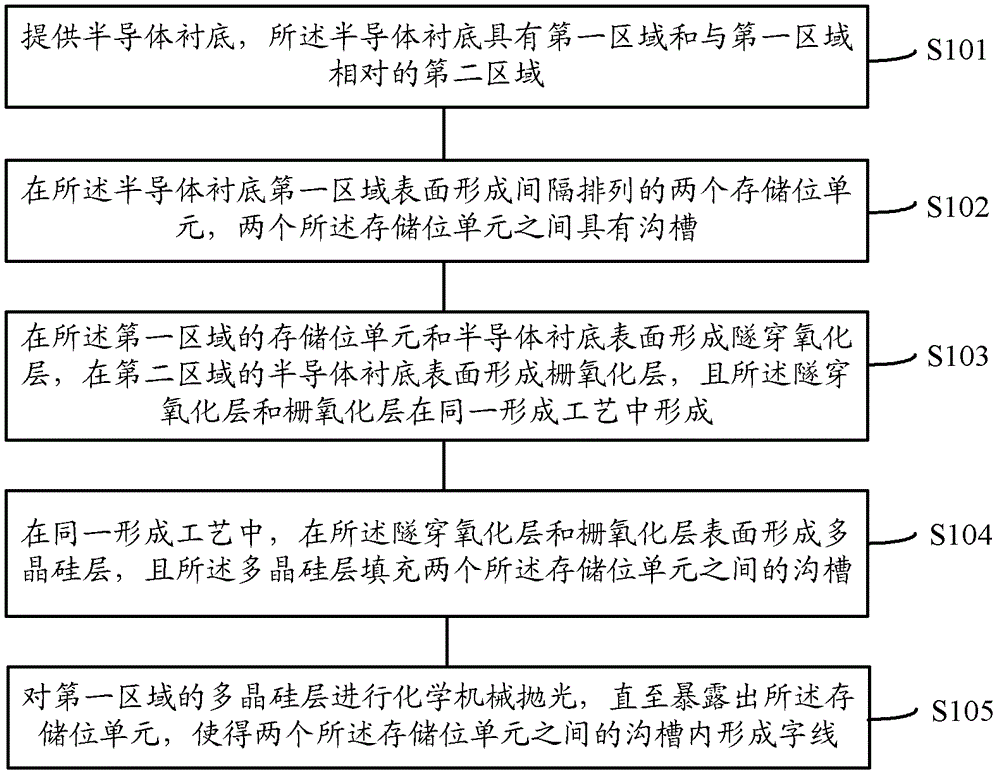

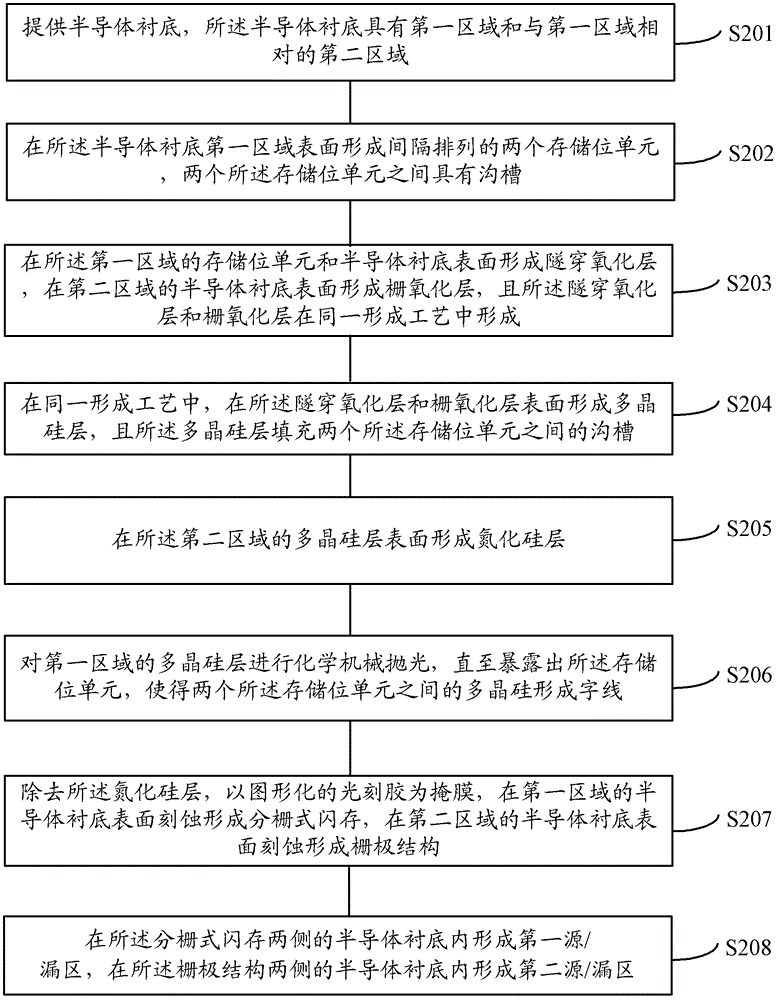

[0031] For this reason, the inventor proposes a kind of semiconductor integrated device manufacturing method through research, please refer to figure 2 ,include:

[0032] Step S101, providing a semiconductor substrate, the semiconductor substrate has a first region and a second region opposite to the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com