Calibration target device and calibration method for three-dimensional ice-shaped digital image system

A digital image and calibration target technology, which is applied in measuring devices, image analysis, image data processing, etc., can solve the problems of measurement error, camera lens distortion, etc., and achieve the effects of improving experimental efficiency, stable performance, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings.

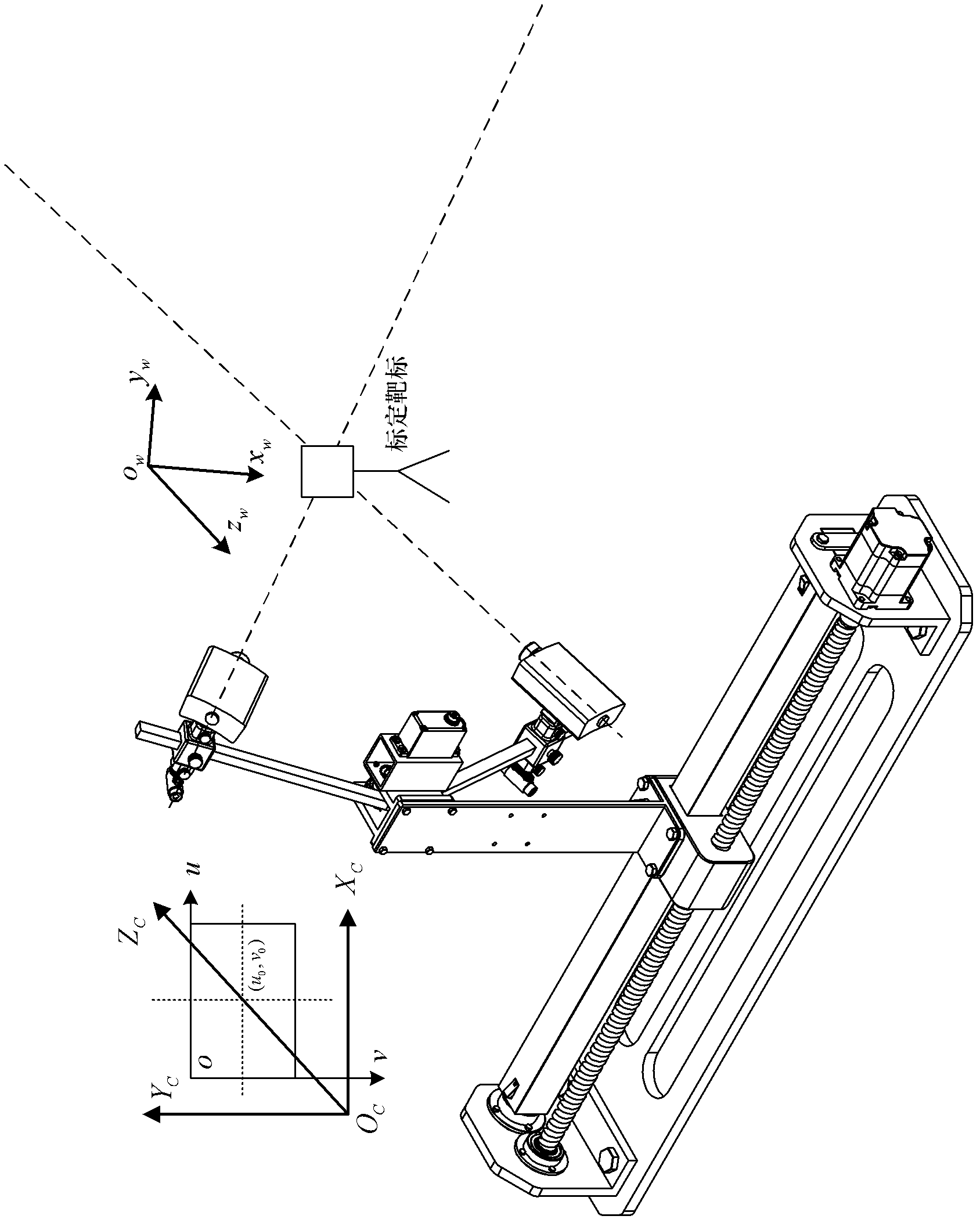

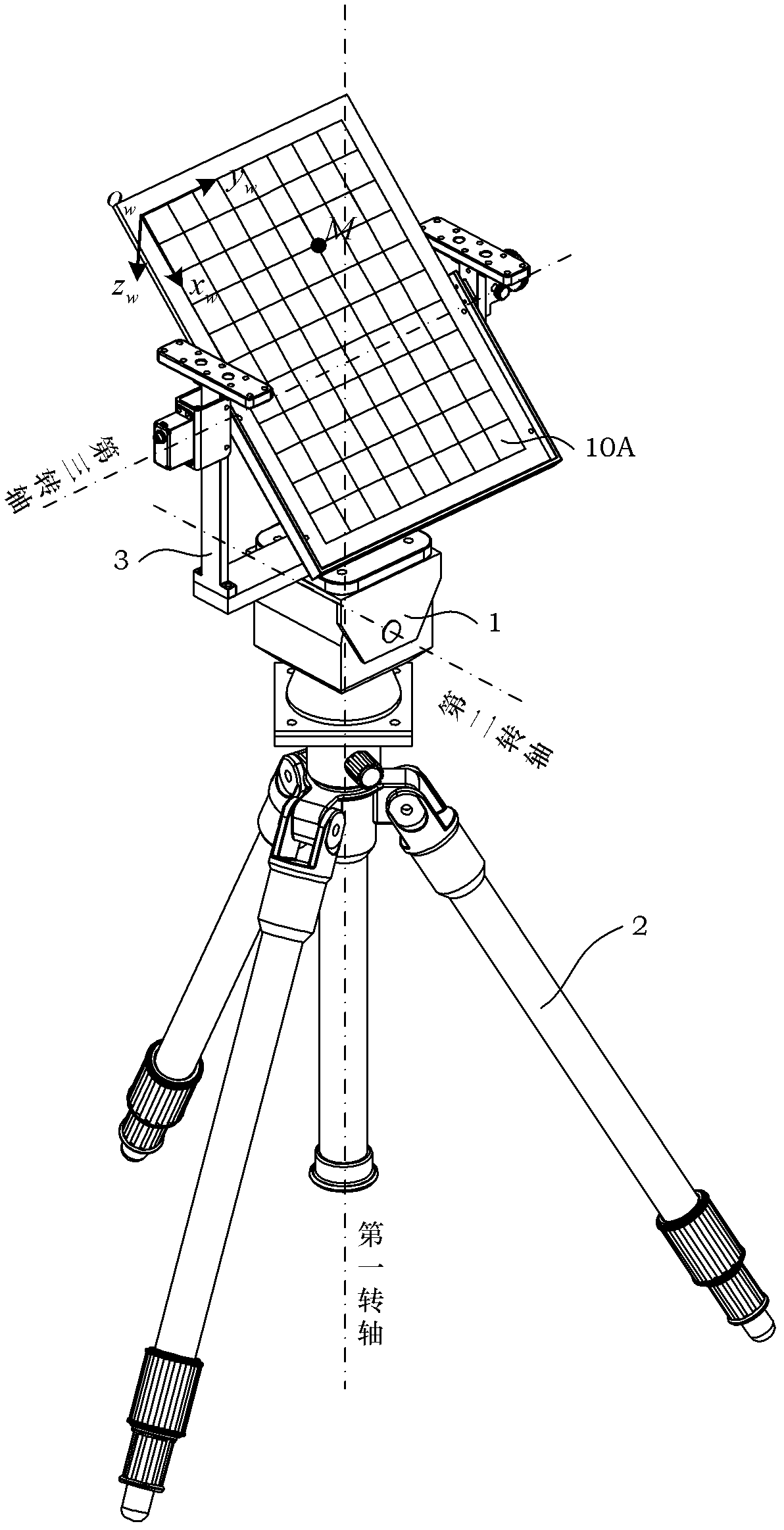

[0030] The three-dimensional ice shape detector (its structure refers to the content disclosed in the patent application No. 201010159240.8) needs to calibrate its camera before use, so as to determine the mapping relationship between the shape and distance of the measured object and the camera image. In order to convert image information in multiple camera coordinate systems in the image processing computer to achieve data splicing and obtain a complete three-dimensional ice-shaped digital image in one image, the relative positional relationship of multiple cameras must be calibrated.

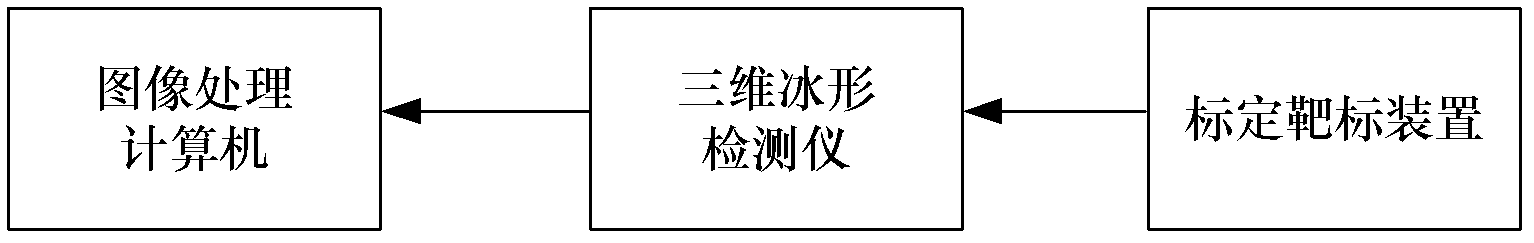

[0031] see figure 1 , Figure 1A As shown, a three-dimensional ice shape digital image system includes an image processing computer, a three-dimensional ice shape detector and a calibration target assembly.

[0032] An image calibration method is run in the image computer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com