Device and method for preparing biomass carbon-based demercuration adsorbents

A biomass carbon and preparation device technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve the problems of shortening biomass carbon-based mercury removal adsorbents, difficult large-scale production, and large heat consumption. Achieve the effects of improving practicability and economy, efficient removal, and optimizing overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

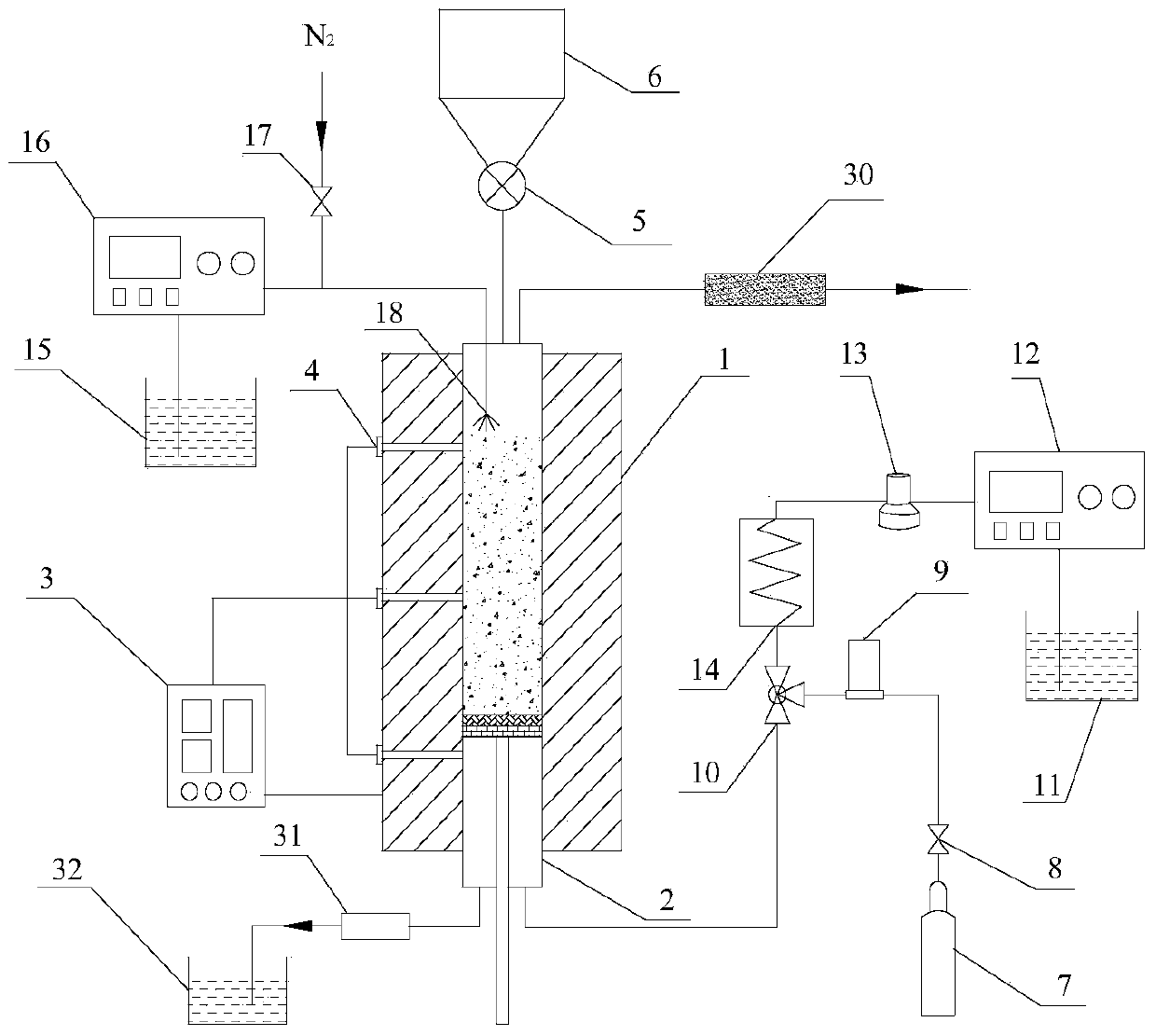

[0035] A method for preparing a biomass carbon-based mercury-removing adsorbent. In this embodiment, peanut shells (PS) are used as raw materials, which are air-dried, crushed and sieved to produce peanut shell particles with a particle size of less than 1 mm.

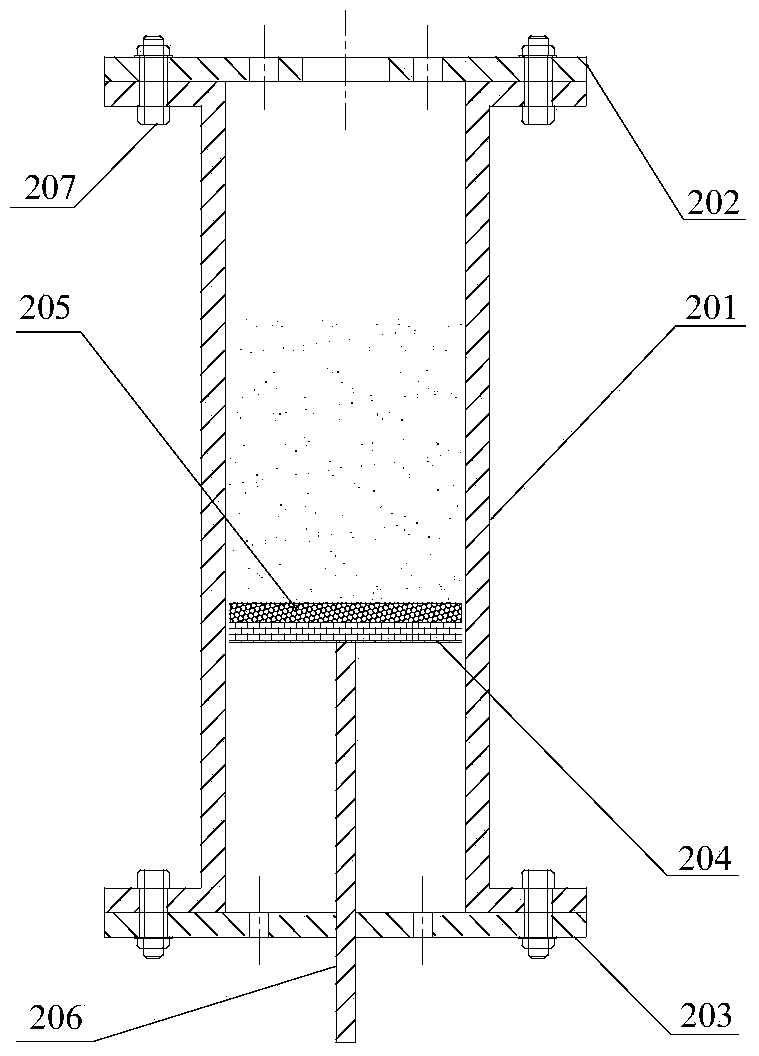

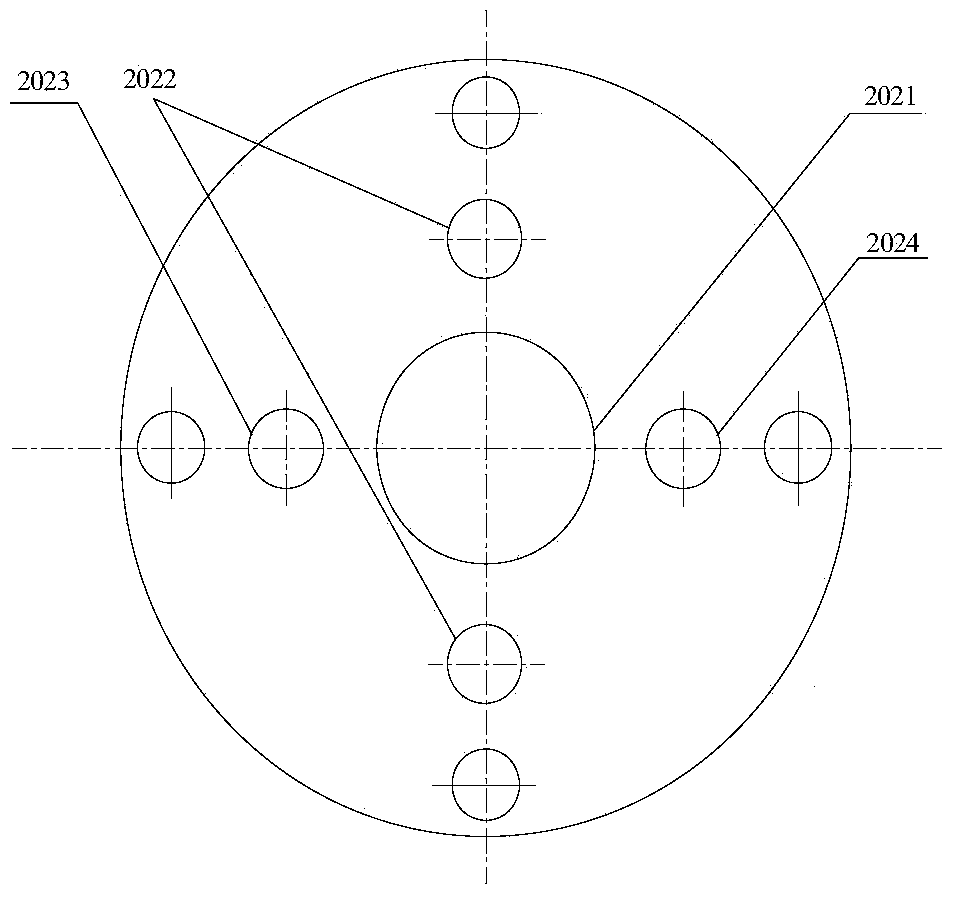

[0036] Take by weighing about 50g peanut shell particle raw material and add to feeding bin 6, in N 2 Under the atmosphere, the temperature of the fixed bed body 2 was raised to 600°C, and then the feeding valve 5 was opened, and the raw material of peanut shell particles was quickly added into the fixed bed, and pyrolyzed for 10 min; Into N 2 , and use a telescopic rake to loosen the pyrolysis of the peanut shells, allow to cool to room temperature, turn off N 2 ; If it is taken out and dried (90°C) and crushed to less than 0.5 mm, the required peanut shell pyrolysis coke (PS600) can be obtained.

[0037] Turn on the constant flow pump 16, deliver the 3% KI modifier solution to the atomizing spray gun 18, and spray ...

Embodiment 2

[0040] The peanut shell pyrolysis coke (PS600), peanut shell impregnated coke (PS600-3%KI) and peanut shell steam activated coke (PS600-3%KI-A) obtained in Example 1 were selected for use in a fixed bed mercury adsorption test device To test its mercury adsorption performance. In the experiment, use N 2 To simulate flue gas, the total flow rate is 2 L / min, and the initial concentration of mercury is 30.2 μg / m 3 , the adsorption temperature is 140 °C, the adsorption time is 160 min, the adsorbent loading is 300 mg, and the superficial velocity is 19108 h -1 . The test results show that the unit mercury adsorption capacity of peanut shell steam activated coke (PS600-3%KI-A) and peanut shell impregnated coke (PS600-3%KI) in Example 1 are 29.14 μg / g and 27.42 μg / g respectively , which are 4.47 times and 4.22 times that of peanut shell pyrolysis (PS600), respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com