Preparation method of hollow-structured micro-array electrode

A micro-array electrode, micro-electrode technology, applied in the directions of micro-structure technology, micro-structure device, manufacturing micro-structure device, etc., can solve problems such as difficulty, difficulty in realizing micro-electrode array heterogeneity, and inability to prepare micro-electrode array, etc. Achieve the effect of low cost, rich structural forms and diverse shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

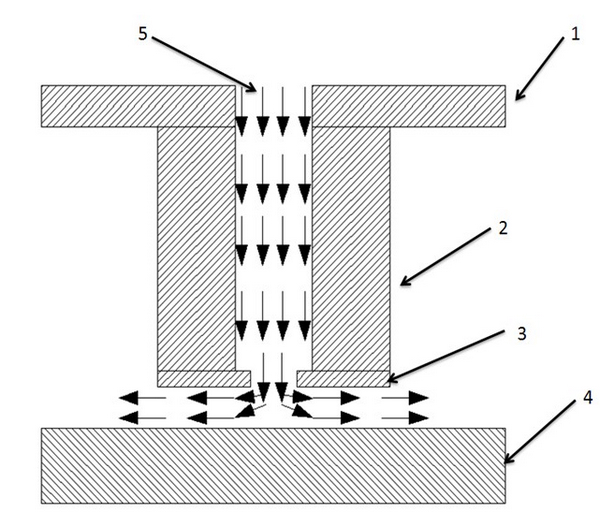

[0035] 1) Make mask plate;

[0036] The production of the electrode is divided into three layers. The mask plate of the first layer can be a film plate, and the mask plate of the second and third layers can be made of a high-precision chromium plate. The mask on the second and third layers of the mask plate is rectangular. ;

[0037] 2) On a 3-inch glass slide, 1um Ti was sputtered at 65°C in a mass fraction of 2% NaOH and 1% H 2 O 2 Oxidation in the mixed solution for 3min to form uniform and dense black TiO 2 To ensure good adhesion between the substrate and the photoresist, dry it at 180°C for 4 hours, then throw the SU-8-50 negative photoresist 300um, and then perform pre-baking, exposure for 180s, and middle-baking in sequence , Development, according to the shape of the electrode designed by the mask plate, the patterning of the support layer of the micro-electrode array bottom plate is realized;

[0038] 3) After removing the residual negative gel...

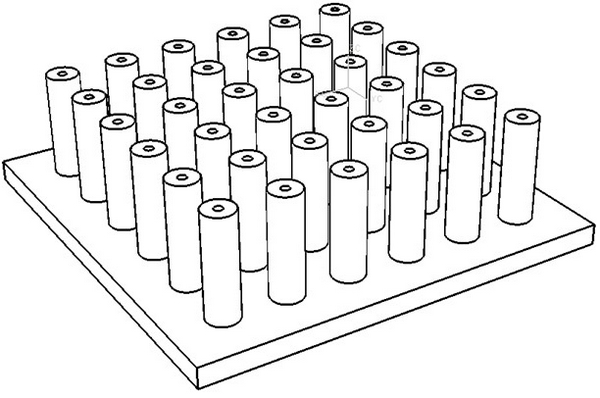

Embodiment 2

[0046] 1) Make a mask; the production of the electrode is divided into three layers, the mask of the first layer can be a film plate, the mask of the second and third layers is a chrome plate with high precision, the second and third layers of masks The mask on the stencil is a triangle;

[0047] 2) On a 4 inch piece of glass, sputter 800 Ti, then repeat step 2) of Example 1 to realize the patterning of the support layer of the microelectrode array bottom plate;

[0048] 3) After removing the residual negative glue on the sheet with a glue remover, perform activation cleaning, and deposit Ni by electrodeposition, and the plating solution is the same as step 3) of Example 1. At a temperature of 45°C, a pH of 4, and a current density of 15mA / cm2, electroplating for 16 hours to obtain a bright, uniform microarray electrode base plate with a thickness of about 300um;

[0049] 4) After flattening the nickel microarray electrode base plate obtained by electroplating wit...

Embodiment 3

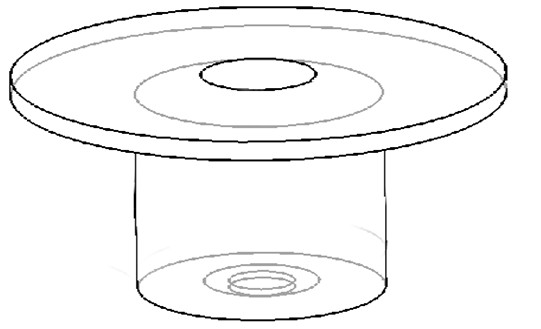

[0056] 1) Make a mask; the production of the electrode is divided into three layers, the mask of the first layer can be a film plate, the mask of the second and third layers is a chrome plate with high precision, the second and third layers of masks The mask on the stencil is circular;

[0057] 2) On a 6-inch piece of glass, sputter 900 Ti, then repeat step 2) of Example 1 to realize the patterning of the support layer of the microelectrode array bottom plate;

[0058] 3) After removing the residual negative glue on the sheet with a glue remover, perform activation cleaning, and deposit Ni by electrodeposition, and the plating solution is the same as step 3) of Example 1. At a temperature of 45°C, a pH of 4, and a current density of 20mA / cm2, electroplating for 12 hours to obtain a bright, uniform microarray electrode base plate with a thickness of about 300um;

[0059] 4) Planarize the nickel microarray electrode bottom plate obtained by electroplating with plana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com