Gate drive thyristor circuit and electrostatic protection circuit

An electrostatic protection and thyristor technology, which is applied in the field of integrated circuit electrostatic protection circuit design, can solve problems such as the inability to meet the needs of long pulse width ESD electrostatic pulse discharge, achieve strong electrostatic discharge capability, and promote the effect of triggering conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

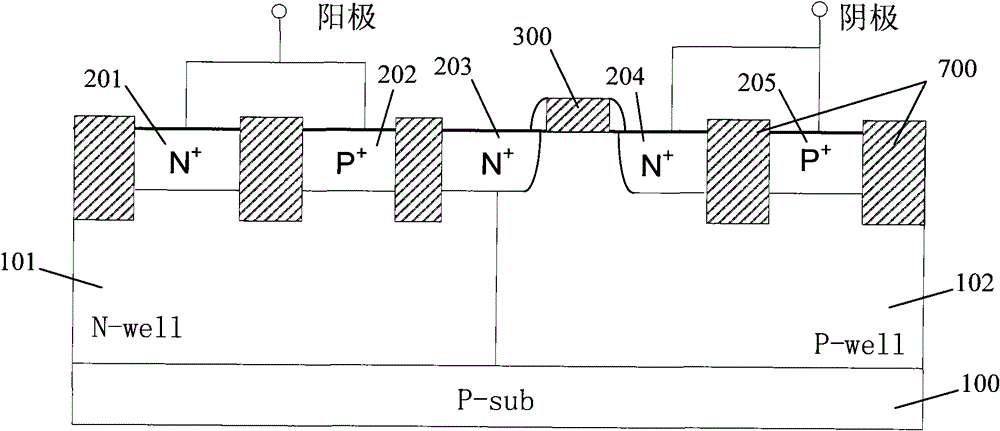

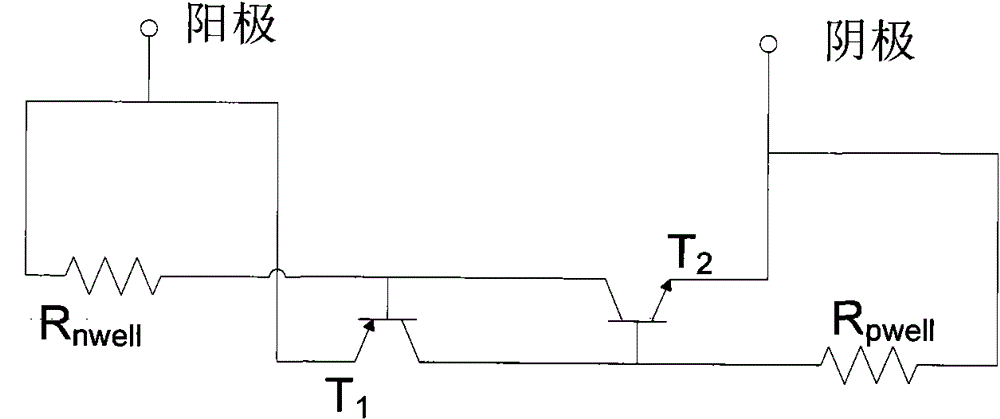

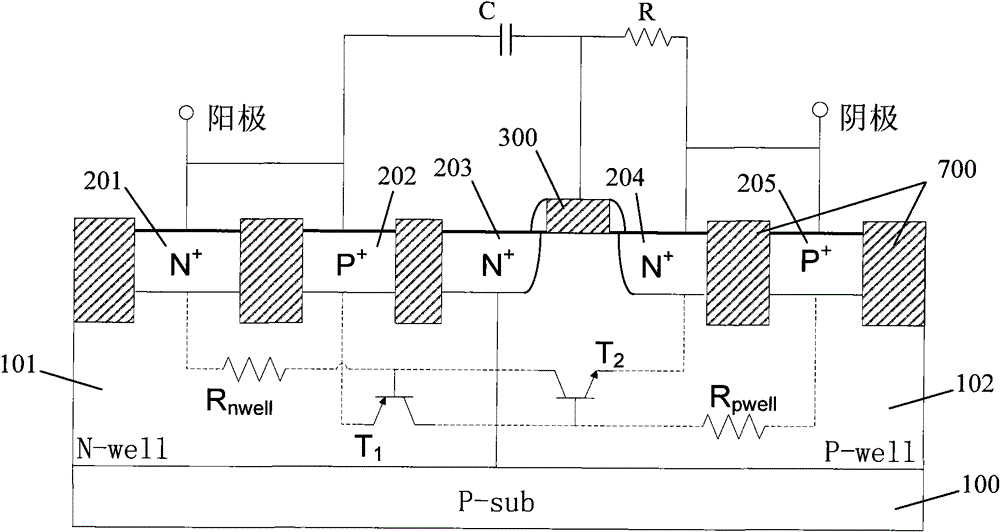

[0040] The existing gate-driven thyristor circuit utilizes the coupling effect of the RC coupling loop to couple the potential of the anode to the control grid to achieve the purpose of reducing the trigger voltage of the thyristor. However, since the coupling effect is not continuous, the potential on the control grid will quickly hysteresis for a long-pulse ESD pulse, and the effect of reducing the trigger voltage of the thyristor is limited. Therefore, it does not meet the requirement of long-term electrostatic discharge. In the gate-driven thyristor circuit provided by the present invention, a forwardly connected diode path is formed between the base (N well) of the parasitic PNP transistor in the PMOS transistor and the control grid, and between the control grid and the cathode (the said between two poles) Connecting diodes in the forward direction refers to connecting the positive end of the diode to the previous pole, and the negative end to the next pole, which is here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com