Method for preparing PVA (polyvinyl alcohol) assisted dispersant for manufacturing polyvinyl chloride by using suspension method

A polyvinyl alcohol and polyvinyl chloride technology, which is applied in the field of preparation of polyvinyl alcohol auxiliary dispersants, can solve problems such as inability to meet customer requirements more efficiently, low porosity efficiency of polyvinyl chloride resin, and post-processing difficulties. Achieve the effects of high absorption value, easier removal, and increased porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

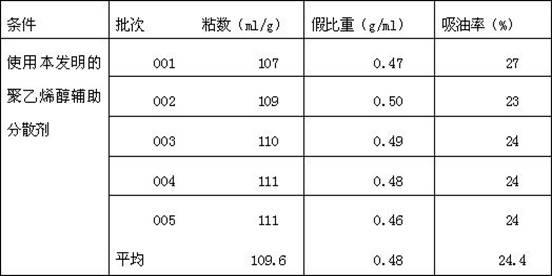

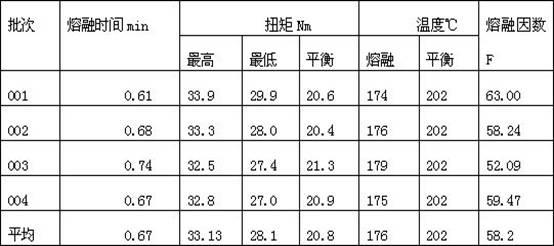

Examples

Embodiment 1

[0048] In the closed autoclave, feed nitrogen to replace the air, then add 100 parts by weight of vinyl acetate monomer, 100 parts by weight of methanol, 3.75 parts by weight of sodium methallylsulfonate, 3.5 parts by weight of ethyl Aldehyde and benzoyl peroxide based on 1.8 parts by weight of vinyl acetate monomers, heating the reactor, heating up to 40°C, and after 10 minutes, continuing to heat up to 65°C for polymerization, after the total polymerization time of 12 hours, when When the conversion rate of vinyl acetate is greater than 92%, add 10 parts by weight of methyl acetate terminator to terminate the polymerization reaction. After the polymerization reaction is completed, heat up to 70°C and distill under reduced pressure for 20 minutes to recover the residual monomers to obtain a copolymer solution for future use. ;

[0049] Add methanol to the standby copolymer solution, dilute to a solid content of 50wt%, to obtain a diluted copolymer solution, take 100 parts by ...

Embodiment 2

[0052] In the autoclave, feed nitrogen to replace the air, add 100 parts by weight of vinyl acetate monomer, 80 parts by weight of ethanol, 1.3 parts by weight of methyl vinyl ether, 0.8 parts by weight of benzaldehyde, then add 0.85 parts by weight Azobisisobutyronitrile, then warming up to 40°C for 10 minutes and then continue to heat up to 62°C for polymerization, the total reaction time is 12 hours, when the conversion rate of vinyl acetate is greater than 92%, add 15 parts by weight of terminator Methanol was used to terminate the polymerization reaction, and the temperature was raised to 70° C. for 20 minutes under reduced pressure to distill the residual monomers to obtain a polymerization solution.

[0053] Methanol was added to the polymer solution, and diluted to a solid content of 40 wt%, to obtain a diluted polymer solution. Take 100 parts by weight of the diluted polymer solution and add it to the alcoholysis tank, add 3.5 parts by weight of 98% concentrated sulfu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Sticky number | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com