Polyvinyl alcohol with advantages of defoaming function and low alcoholysis degree, and preparation method thereof

A technology of polyvinyl alcohol and alcoholysis degree, applied in the field of preparation of polyvinyl alcohol, can solve the problems of SPVC quality decline, environmental pollution, high organic content in mother liquor, and achieve the effect of cost economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

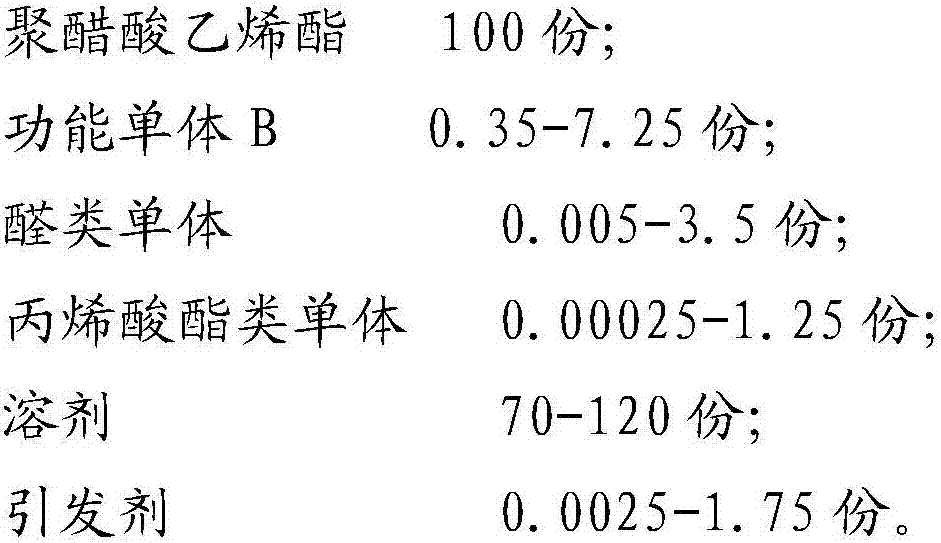

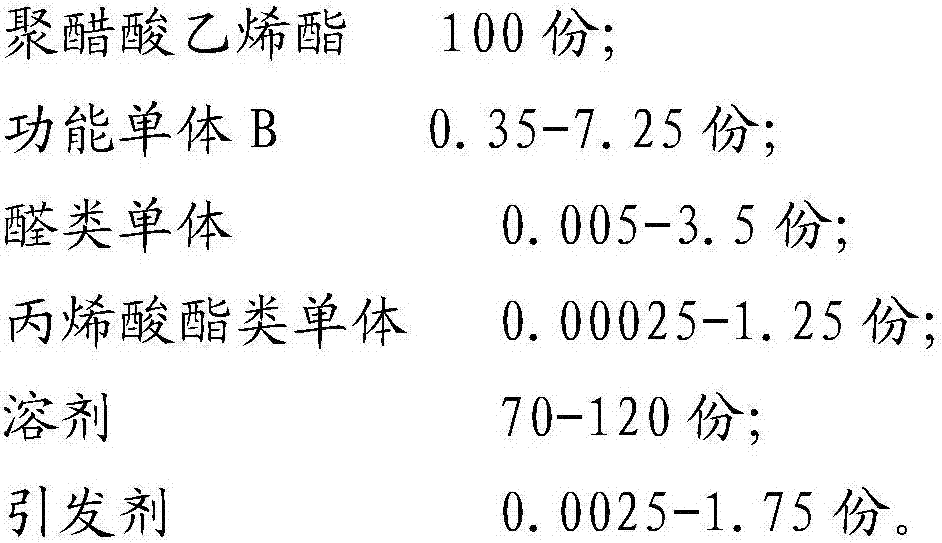

Method used

Image

Examples

Embodiment 1

[0034] a): In a 1-liter airtight normal-pressure polymerization kettle, feed nitrogen to replace the air, then add 100g vinyl acetate, 100g methanol solvent, and then add functional monomer B 1.75g sodium methallyl sulfonate And 0.35g of tert-butyl acrylate, 3.5g of acetaldehyde, and finally 1.75g of dibenzoyl peroxide. Heat the reactor, raise the temperature to 50°C and react for 10 minutes, then continue to raise the temperature to 65°C to start calculating the polymerization time. After the total reaction time is 12 hours, add 10 g of methyl acetate to terminate the polymerization. After the polymerization, the temperature was raised to 70° C. for 45 minutes under reduced pressure and the residual monomer was recovered to obtain a polyvinyl acetate solution. Adding methanol to the polyvinyl acetate polymer, diluting the solid content to 45wt%;

[0035] b): Then add 100 g of diluted polymer in a 1 liter alcoholysis tank, add 70 g of sodium hydroxide methanol solution wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com