Method suitable for continuously preparing high-temperature superconductive belt material

A high-temperature superconducting strip and superconducting layer technology, which is applied in the manufacture/processing of superconductor devices, the plating of superimposed layers, and the coating process of metal materials, can solve the problem of reducing laser utilization, strip preparation speed, and raw materials. High cost, barriers to cost performance, etc., to achieve the effect of improving laser utilization and strip preparation speed, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

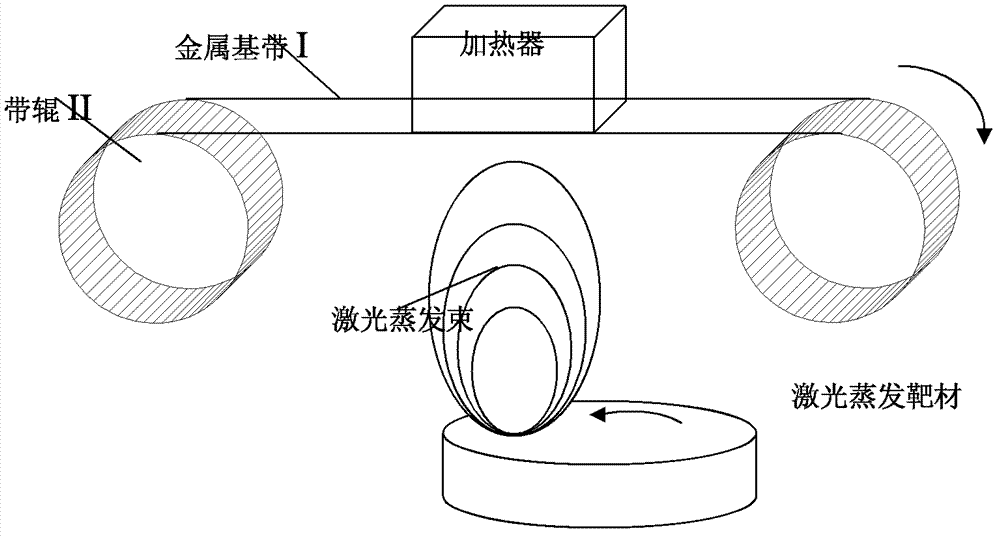

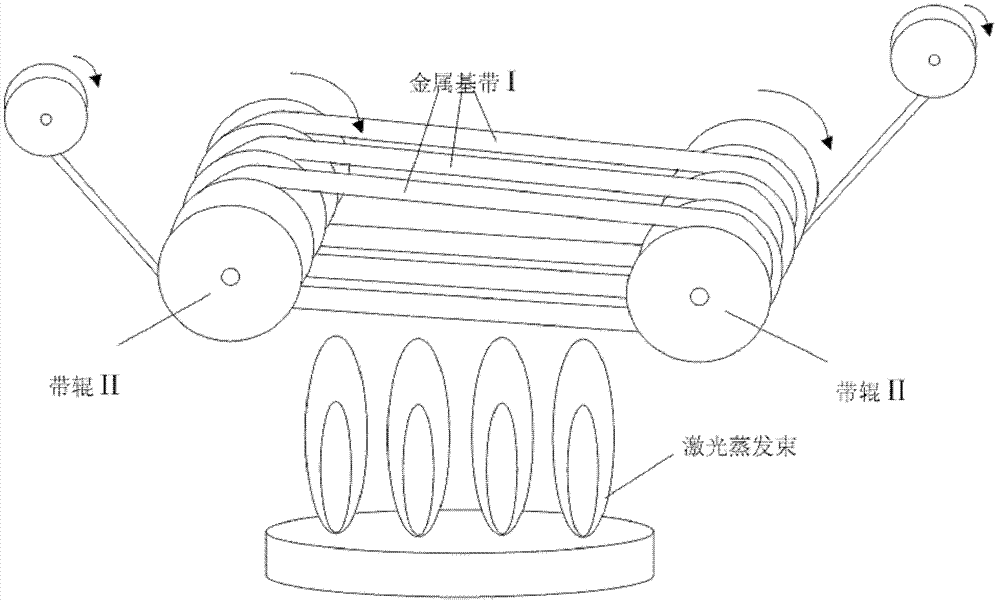

[0024] Such as image 3 As shown, this embodiment includes the following steps:

[0025] Step 1, preparation of metal baseband;

[0026] The metal substrate adopts a biaxially textured nickel-tungsten alloy strip (Rolled Assisted Biaxially Textured Substrates, abbreviated as RABiTS), Ni-5%W alloy; or an ion beam assisted deposition method (Ion Beam Assisted Deposition, abbreviated as IBAD) The prepared metal alloy strip with biaxial texture structure, such as Hastelloy strip (C-276), or stainless steel strip, etc.

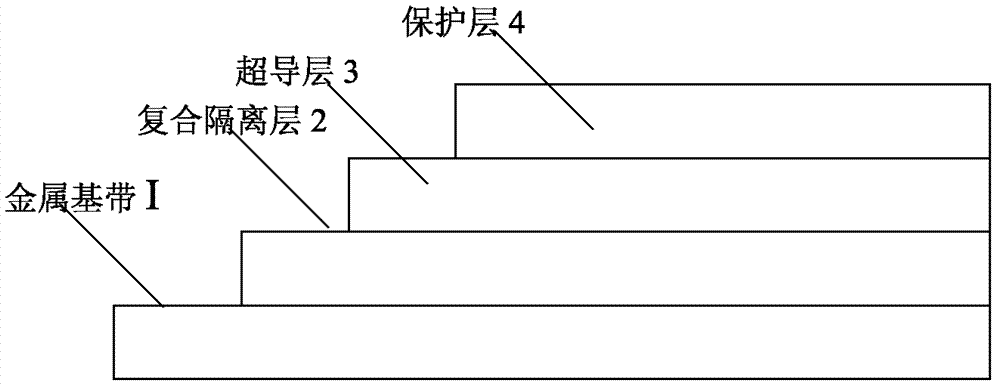

[0027] Step 2, using a laser coating method to grow a composite isolation layer on the metal substrate;

[0028] The composite isolation layer can adopt CeO 2 , or YSZ, or Y 2 o 3 , or SrTiO 2 , or La 2 Zr 2 o 7 , or LaMnO 3 , or MgO, or NiO, or oxide composite multilayer structure, such as metal substrate / CeO 2 / YSZ / CeO 2 , or metal baseband / Y 2 o 3 / YSZ / CeO 2 , or metal baseband / CeO 2 / SrTiO 3 , or metal baseband / CeO 2 / La 2 Zr 2 o 7 , CeO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com